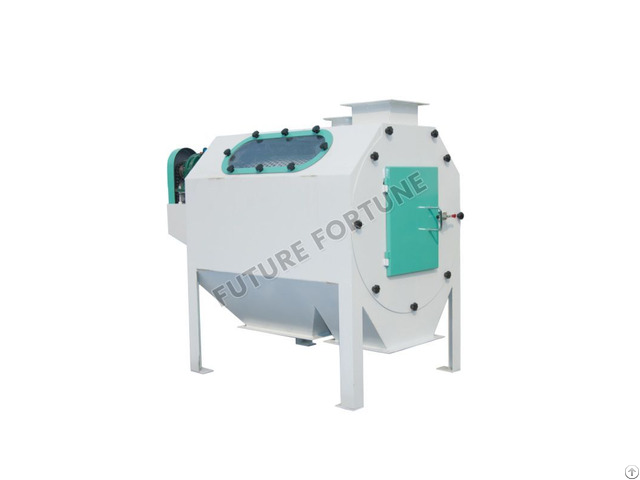

Animal Feed Processing Equipment - China

price: 1.00 Dollar US$

Future Fortune is a leader in the design and manufacture of milling equipment for feed and grain processing, with thousands of installations to date.

We optimize the performance of our equipment to meet the unique needs of feed processors, and we can produce the most tightly distributed uniform particle size with the least amount of dust.

All equipment is available in carbon or stainless steel construction and can be custom configured to meet your material and production goals.

Animal Feed Processing Equipment

The main components of the feed mill equipment in the feed pellet factory are a feed mill, feed mixer, feed pellet machine, feed pellet cooler and feed pellet packaging machine.

The auxiliary equipment of the feed factory includes conveyors, control cabinets, storage bins, dust collectors, fire-fighting equipment, etc.

Equipment for Animal Feed

Basic feed mill equipment operations to produce animal or poultry feed pellets include raw material receiving, grinding, batching, mixing, pelleting, cooling, screening, packaging and warehousing.

Raw material receiving

Feed mills are often equipped to receive grain and other raw materials for rail and truck shipments.

Natural materials such as meat, fishmeal, fat, molasses and premixes are transported by truck, while grain and soybean meal are often fascinated by rail.

Dry ingredients are received in bulk or in bags; liquid ingredients such as fat and molasses are pumped directly into storage tanks in the feed mill; elements such as bulk grain are conveyed by conveyors or bucket elevators to the cleaning machine to remove non-metallic foreign matter and metal impurities material, and then stored in the storage bin.

Grinding

Whole grains require a feed hammer mill before being mixed with other feed ingredients grind.

Batching According to the feed formula, it is necessary to quantitatively weigh various feed materials with a batching scale.

The quantity of various ingredients fed into the scale hopper is manually or automatically controlled by the central control panel.

Mix

Each batch of feed ingredients is mixed evenly in the feed mixer.

The mixing time depends on the feed formula and the characteristics of the feed ingredients and feed mixer.

Pellet

Send the evenly mixed feed raw materials into the feed pellet machine.

The granulation process involves several steps.

First, the mixed raw materials are sent to the feeder of the pellet mill, and the feeder is used to control the rate at which the raw materials are conveyed to the feed pelletizing equipment; secondly, the dry blended materials and added steam are mixed together in the conditioner, A wet paste is formed, which is then fed by gravity or forced feeding system into the granulation chamber where the hot, moist paste is pushed through the granulator die and converted to particle size and shape.

Cooling, sieving

The hot feed pellets are gravity-fed into a pellet cooler, resulting in durable, hard pellets.

The cooled granules flow directly into a screening machine to remove granular paste and fines.

Packaging and storage

The finished pellet feed is weighed, packed and sealed by the pellet packaging machine and then transported into the warehouse.

Company Contact:

- Posted By: Future Fortune International Trading (Shanghai) Co., Ltd.,Future Fortune Industry Co.,Ltd.

- Phone: 13817519738

- Address: 20, No.1-42 Of Lane 83, Hongxiang North Road, Pudong New District, Shanghai , Shanghai , China

- Email:

Published date: October 20, 2023

- Business Description: Future Fortune is a leading manufacturer and professional supplier of animal nutrition equipment and accessories.

With excellent technology and advanced equipment, strict quality control management, and more than twenty experienced experts in aliment nutrition field, our products Aliment security controller, Auto-weighing, Mixer, Grinding, Pelletizing, Hammer Mill, Extruder, Dryer, Cooler, Conveyors, Stabilizer.

are exported to many countries.

Future Fortune is not only dedicated to provide high-quality spare parts & machinery and reliable service to customers, but also aims to be the professional partner who can provide technical solutions, and production & management suggestions and ideas in designing, installation, training and guiding which assures customers operative production.

Future Fortune is turning to be your one stop feed machinery partner.

Our Products:

- Granule And Cylinder Precleaner

- Grinding Pelletfeed

- Impeller Feeder Twly Series

- Mixing Pelletfeed

- Pelleting Pelletfeed

Related listings

-

Perlove Medical With Fast Shipments Pl300bPrefabricated buildings and structures - Nanjing Perlove Medical Equipment Co.,ltd - China - October 17, 2023 - 40000.00 Dollar US$

Perlove Medical With Fast Shipments Pl300bPrefabricated buildings and structures - Nanjing Perlove Medical Equipment Co.,ltd - China - October 17, 2023 - 40000.00 Dollar US$Perlove, a leading name in advanced medical technology, is thrilled to announce its participation in the upcoming Medic West Africa 2023 exhibition. As the premier healthcare event in the region, Medic West Africa provides an exceptional platform for...

-

Perlove Medical With Fast Shipments Plx5200a 50kwPrefabricated buildings and structures - Nanjing Perlove Medical Equipment Co.,ltd - China - October 17, 2023 - 40000.00 Dollar US$

Perlove Medical With Fast Shipments Plx5200a 50kwPrefabricated buildings and structures - Nanjing Perlove Medical Equipment Co.,ltd - China - October 17, 2023 - 40000.00 Dollar US$Perlove is thrilled to announce our participation in the highly anticipated Philippines Medical Expo . As a leading provider of cutting-edge medical equipment, we are excited to showcase our latest innovations and connect with healthcare professional...

-

Perlove Medical With Fast Shipments Plx116bPrefabricated buildings and structures - Nanjing Perlove Medical Equipment Co.,ltd - China - October 17, 2023 - 40000.00 Dollar US$

Perlove Medical With Fast Shipments Plx116bPrefabricated buildings and structures - Nanjing Perlove Medical Equipment Co.,ltd - China - October 17, 2023 - 40000.00 Dollar US$(2) The incision during the operation is 5 mm. With the high -definition image of the large field of view of the PLX119C, the direction of the needle and the depth of the needle are determined. Put the vertebral root of the vertebral bow to the verte...

Safe Trade Tips

- Ask for business references and check them

- Use a payment method that offers better protection for all such as Letters of credit and verified professional escrow services. Avoid payments in advance such as money transfers

- Verify their business via their local Chamber of Commerce

- Search the internet using their website address, their business name, their phone and fax numbers, and their email addresses to see if you can find any feedback about them.

- Get to know more about scams and fraud to avoid: Internet Crime Complaint Center - Consumer Financial Protection Bureau

- This site is never involved in any transaction, and does not handle payments, shipping, guarantee transactions, provide escrow services, or offer "buyer protection" or "seller certification"