Tungsten Carbide Button Bits - China

price: contact company for price

Tungsten Carbide Button Bits JIMS CARBIDE is one of the premier carbide manufacturing companies.

We offer world class carbide miling for hard rock mining bits, DTH hammer bits, O&G roller cone bits, polycrystalline diamond substrates and cone picks.

Through years of technical improvements and equipment optimization, JIMS CARBIDE has developed the GM, KM and JCK series carbide grades with an annual production capacity of over 800 metric tons/year.

In a wide range of geological formations, JIMS CARBIDE has proven to be a strong performer against competitors around the world.

As a result of our consistently high quality standards, JIMS CARBIDE has received several certified supplier awards from internationally recognized companies.

Carbide Grades

Grade Co(%) Hardness

[HRA) TRS

(Nmm) Recommended Use

GM06 6 90.3 2800 DTH hammer, medium

to hard rock

KM65 6.5 90 3000 GM08 8 88.7 3200 J510 10 88.1 3300 Roller cone dril bit

J411 11 88.8 3200 J512 12 87.3 3200 JCK 1 10 85.7 2400 Road milling, mining

JCK 3-S 6.5 87.5 2200 YH13 13 88.7 3500 PDC Substrate

YH16 16 86.6 3200

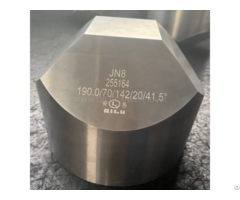

Type Dimensions(mm) D H h R e

Q0810 8 10 7.1 4.2 1

Q0812 8 12 9.1 4.2 1.0

Q1010 10 10 6.3 5.2 1.5

Q1012 10 12 8.3 5.2 1.5

Q1014 10 14 10.3 5.2 1.5

Q1214 12 14 9.4 6.2 1.5

Q1216 12 16 11.4 6.2 1.5

Q1218 12 18 13.4 6.2 1.5

Q1416 14 16 10.5 6.2 1.5

Q1422 14 22 16.5 7.2 1.5

Q1625 16 25 18.6 8.2 1.5

Q1827 18 27 19.8 9.2 1.5

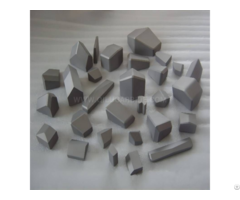

Tungsten Carbide Bits/Button/Drill Bits

Tungsten carbide button bits are drilling tools used in the mining and construction industries for drilling through hard rock formations.

They are made of a composite material consisting of tungsten carbide grains, which are cemented together with a metallic binder such as cobalt or nickel.

The resulting material is extremely hard and wear-resistant, making it ideal for use in drilling applications.

The button bits themselves consist of a bit body and a series of tungsten carbide buttons arranged in a specific pattern on the face of the bit.

The buttons are the primary cutting elements and are designed to fracture the rock as the bit is rotated and forced into the formation.

There are several different types of tungsten carbide button bits, each designed for specific drilling applications.

For example, conical button bits have a tapered shape and are ideal for drilling in soft to medium-hard formations, while chisel bits have a flat shape and are used for drilling in harder formations.

The design and arrangement of the tungsten carbide buttons on the bit face can also vary depending on the specific drilling application.

For example, cross-shaped button arrangements are commonly used for drilling in harder formations, while dome-shaped button arrangements are used for drilling in softer formations.

Tungsten carbide button bits are typically used in conjunction with rotary drilling equipment, which provides the rotational force needed to turn the bit and penetrate the rock formation.

The bit is attached to the end of a drill string and lowered into the borehole, where it is rotated at high speed while being pushed into the formation.

As the buttons on the bit face make contact with the rock, they fracture it into small pieces, which are then removed from the borehole by a drilling fluid such as mud or air.

Tungsten carbide button bits are essential tools for drilling through hard rock formations in mining and construction applications.

They are made of a composite material consisting of tungsten carbide grains and a metallic binder, and feature tungsten carbide buttons arranged in a specific pattern on the bit face for efficient rock penetration.

Company Contact:

- Phone: 15216418689

- Address: No. 18111, Jingshi East Road, Zhangqiu City, Shandong Province, China

- Email:

Published date: April 14, 2023

- Business Description: JINAN INSTITUTE OF METALLURGICAL SCIENCE CO., LTD. is a premier cemented carbide manufacturing company.

JIMS CARBIDE is an industry leader with over 40 years of carbide manufacturing experience and is actively engaged in the research and development of advanced tungsten carbide products that we supply to our customers globally.

To continually drive Innovation, Product Development and Process Improvement over 35% of our total 600 member team are Engineers.

JIMS CARBIDE has invested in state of the art production equipment throughout our operations and has a world class quality management system In 2005, JIMS CARBIDE received IS09001 Quality Management System Certification.

Our Products:

- Cemented Carbide Anvil

- Tungsten Carbide Tbm Shield Cutter Teeth

- Customized Cemented Carbide Plate Sheet Flat

- Tungsten Carbide Button Bits

- Tungsten Carbide Solid

Related listings

-

Customized Cemented Carbide Plate Sheet FlatAdvertising - Jinan Institute of Metallurgical Science Co., Ltd. - China - April 14, 2023 - contact company for price

Customized Cemented Carbide Plate Sheet FlatAdvertising - Jinan Institute of Metallurgical Science Co., Ltd. - China - April 14, 2023 - contact company for priceCustomized Cemented Carbide Plate/Sheet/Flat Carbide Plate is a high-quality, durable material that is used in a wide range of industrial applications. Made from tungsten carbide, this flat stock material is known for its exceptional hardness and str...

-

Tungsten Carbide Tbm Shield Cutter TeethAdvertising - Jinan Institute of Metallurgical Science Co., Ltd. - China - April 14, 2023 - contact company for price

Tungsten Carbide Tbm Shield Cutter TeethAdvertising - Jinan Institute of Metallurgical Science Co., Ltd. - China - April 14, 2023 - contact company for priceTungsten Carbide TBM Shield Cutter Teeth JIMS CARBIDE is one of the first carbide manufactures to invest in Research & Development and commercial production of Geological Carbide Inserts used in the Drilling and Tunneling markets. Through years o...

-

Cemented Carbide AnvilAdvertising - Jinan Institute of Metallurgical Science Co., Ltd. - China - April 14, 2023 - contact company for price

Cemented Carbide AnvilAdvertising - Jinan Institute of Metallurgical Science Co., Ltd. - China - April 14, 2023 - contact company for priceCemented Carbide Anvil Product Description: Summation of All Advanced Technology and Precised Production Experience. >Ultimate Tungsten Carbide Technology and Experience >Durable to Extreme High Temperature and Pressure >Precise Machining fo...

Safe Trade Tips

- Ask for business references and check them

- Use a payment method that offers better protection for all such as Letters of credit and verified professional escrow services. Avoid payments in advance such as money transfers

- Verify their business via their local Chamber of Commerce

- Search the internet using their website address, their business name, their phone and fax numbers, and their email addresses to see if you can find any feedback about them.

- Get to know more about scams and fraud to avoid: Internet Crime Complaint Center - Consumer Financial Protection Bureau

- This site is never involved in any transaction, and does not handle payments, shipping, guarantee transactions, provide escrow services, or offer "buyer protection" or "seller certification"