Hitachi Sigma G5 Pick And Place Machine - China

price: 65000.00 Dollar US$

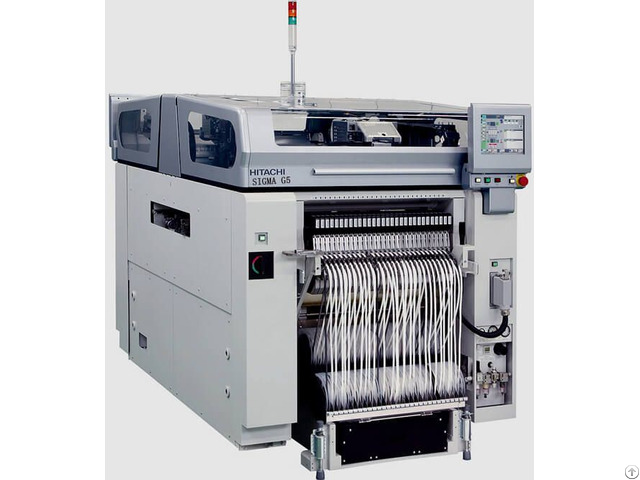

Hitachi SIGMA G5 Pick and Place Machine

Mounting Speed: 84500chip

Placement range 1005 (0402) -32mmIC

Placement accuracy: 0.03mm

Product description: Hitachi SIGMA G5 Pick and Place Machine INQUIRY

Hitachi SIGMA G5 pick and place machine Products Description:

suctioned and installed for high throughput By matching the head module to the parts supply module, a device that conforms to the production mode can be configured on any two of the two processing zones By using gull-wing covers and securing the working area between the devices when connecting, an excellent working environment is achieved Front and rear equipped with a large touch panel monitor, thereby enhancing the operating performance 2 - Mounting head module of the stress

According to production patterns for high-speed placement head, multi-functional placement of the first free combination of configuration.

High-speed placement head through the replacement nozzle to achieve a variety of parts 0402 ~ 44mm stress Parts with a maximum of 55 mm, connectors with a maximum length of 100 × 26 mm, and parts with a thickness up to 25.4 can be produced using the multi-purpose mounting head.

3 - Linear motor drives XY axes

Equipped with a fully enclosed linear scale control

Equipped with an intermeshing control device that can monitor two Y axes with each other, a rigid dual drive is achieved, enabling high-speed, high-precision positioning.

Through the use of linear motors, to simplify the structure, resulting in long-term maintenance-free

4 - Module placement machine equipped with a direct drive head

Hitachi alone direct drive head servo motor, so as to achieve a higher accuracy

Each drive head can suck up to 15 suction nozzle, through the adsorption of 15 components, reducing the number of XY axis reciprocation, enabling high productivity Nozzle holder can be easily removed, you can replace the nozzle outside the placement machine

5 - Achieve high speed through non-stop batch identification

Each processing area equipped with component recognition camera

Through the XY axis synchronization control, high-intensity strobe flash and the establishment of telecentric lens, to achieve the highest speed camera A one-time video capture of 15 components was achieved

6 - Each placement head is equipped with a laser sensor to check the number of components (whether the erection, the level of absorption) for a full inspection, and the stable mounting of a very small patch by feedback of the pickup height.

7 - Enables high-throughput substrate Y position adjustment

The Y position of the substrate can be adjusted to the optimum position according to the size of the substrate and the number of mounting components between the front and rear axles.

This adjustment can improve the balance of the coordinated actions of the front and rear axles to achieve high output.

8 - High intelligent feeding system

8mm double belt feeder can carry up to 120 varieties.

Tracking pitch can be changed by program setting.

Through the splicing of the belt, components can be supplied during operation to reduce the non-working time

One-time change of trolleys by the feeders makes it possible to change one feeder to another one at a time.

9 - Multi-section pallet feeders can be set up anywhere in the entire processing area

Keywords: China reflow oven, Pick and place machine factory, China chip mounter, SMT chip mounter Manufacturer, Lead Free Reflow Oven factory, wave soldering machine manufacturer, pick and place machine supplier.

Flason Electronic Co., ltd provide a full smt assembly line solutions, including Lead free reflow oven, wave soldering machine, SMT pick and place machine, smt stencil printer, PCB conveyor manufacturer, PCB unloader, chip mounter, SMT AOI machine, SMT SPI machine, SMT X-Ray machine, SMT assembly line equipment, PCB production Equipment smt spare parts etc any kind SMT machines you may need, please contact us for more information: wechat whatsapp: 008613691605420, Skype: flasonsmt, Email: sales@flason-smt.

com

Company Contact:

- Posted By: flason electronic co.,ltd

- Phone: 86 755 85225569

- Address: flason industry park shajing town baoan district shenzhen china, shenzhen , guangdong , China

- Email:

- Website: https://www.flason-smt.com

Published date: August 24, 2018

- Business Description: Flason Electronic Co., ltd provide a full SMT assembly line solutions, including SMT reflow oven, THT wave soldering machine, pick and place machine, solder paste printer, PCB loader, PCB unloader, chip mounter, SMT AOI machine, SMT SPI machine, SMT X-Ray machine, SMT assembly line equipment, PCB production Equipment etc any kind SMT machines you may need, please contact us for more information: wechat whatsapp: 008613691605420, Skype: flasonsmt, Email: sales@flason-smt.

com

Related listings

-

Hitachi Sigma G4 Pick And Place MachineElectrical equipment and components - flason electronic co.,ltd - China - August 24, 2018 - 9300.00 Dollar US$

Hitachi Sigma G4 Pick And Place MachineElectrical equipment and components - flason electronic co.,ltd - China - August 24, 2018 - 9300.00 Dollar US$Hitachi SIGMA G4 Pick and Place Machine Quick exchange Super wide range DDH Product description: Hitachi SIGMA G4 Pick and Place Machine INQUIRY Hitachi SIGMA G4 pick and place machine Products Description: A. Wide range of direct drive is type mount...

-

Juki Ke 760 Pick And Place MachineElectrical equipment and components - flason electronic co.,ltd - China - August 24, 2018 - 65000.00 Dollar US$

Juki Ke 760 Pick And Place MachineElectrical equipment and components - flason electronic co.,ltd - China - August 24, 2018 - 65000.00 Dollar US$JUKI KE-760 Pick and Place Machine 1400 × 1300 × 1551㎜ Component range: 0402 ㎜ Weight: 1150㎏ Product description: JUKI KE-760 Pick and Place Machine INQUIRY juki KE-760 pick and place machine Products Description: Used JUKI760 placement machine is a ...

-

Yamaha Ys88 Pick And Place MachineElectrical equipment and components - flason electronic co.,ltd - China - August 24, 2018 - 45000.00 Dollar US$

Yamaha Ys88 Pick And Place MachineElectrical equipment and components - flason electronic co.,ltd - China - August 24, 2018 - 45000.00 Dollar US$Yamaha ys88 Pick and Place Machine components heights up to 25.5mm +/-30μm QFP mounting 8, 400CPH Product description: Yamaha ys88 Pick and Place Machine INQUIRY yamaha ys88 pick and place machine Products Description: By holding up to 119 feeding po...

Safe Trade Tips

- Ask for business references and check them

- Use a payment method that offers better protection for all such as Letters of credit and verified professional escrow services. Avoid payments in advance such as money transfers

- Verify their business via their local Chamber of Commerce

- Search the internet using their website address, their business name, their phone and fax numbers, and their email addresses to see if you can find any feedback about them.

- Get to know more about scams and fraud to avoid: Internet Crime Complaint Center - Consumer Financial Protection Bureau

- This site is never involved in any transaction, and does not handle payments, shipping, guarantee transactions, provide escrow services, or offer "buyer protection" or "seller certification"