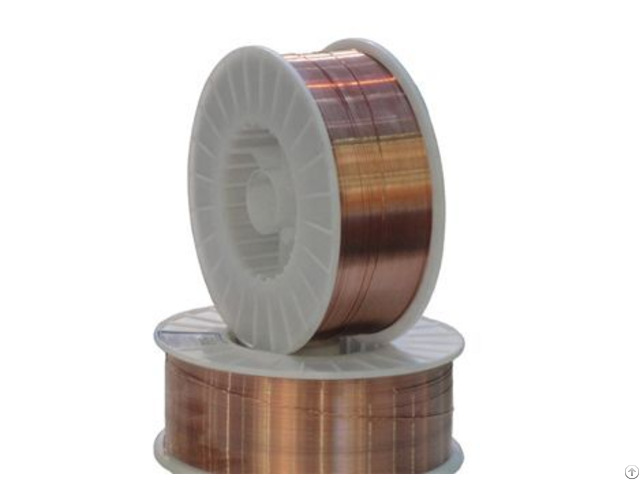

Mig And Tig Wires - China

price: 1.00 Dollar US$

MIG and TIG wires are integral components in the welding processes known as MIG (Metal Inert Gas) and TIG (Tungsten Inert Gas) welding, respectively.

MIG wire is commonly used in welding applications requiring higher temperatures, such as aluminum and steel welding.

TIG wire, such as stainless steel and copper, is commonly used for welding at lower temperatures.

Each type of wire serves a distinct purpose and is designed for specific applications.

What is the Difference Between MIG and TIG Wires?

MIG and TIG wires are essential components in their respective welding processes, each with unique characteristics and applications.

Understanding the differences between them can help in selecting the appropriate method for specific projects.

Differences Between MIG and TIG Wires 1 - Welding Process MIG Wire: Used in MIG welding (Gas Metal Arc Welding), where a continuous feed of consumable wire acts as both the electrode and filler material.

The process is semi-automatic or automatic, making it faster and suitable for larger production runs.

TIG Wire: Utilized in TIG welding (Gas Tungsten Arc Welding), where a non-consumable tungsten electrode creates the arc.

A separate filler rod is manually fed into the weld pool, allowing for greater control but requiring more skill and time.

2 - Weld Quality and Strength MIG Welding: Produces strong welds suitable for thicker materials, but may have more defects due to its faster process.

The welds are generally less aesthetically pleasing compared to TIG welds.

TIG Welding: Known for producing high-quality, clean, and aesthetically pleasing welds.

TIG welds are often stronger due to better penetration and fewer defects, making this method ideal for thin materials.

3 - Speed and Efficiency MIG Welding: Significantly faster than TIG welding because of its continuous wire feed system.

This efficiency makes it preferable for large-scale projects or when speed is critical.

TIG Welding: Slower due to the manual feeding of filler rods and the requirement for precise control.

This method is better suited for detailed work where quality is paramount.

4 - Material Compatibility MIG Wire: Commonly used for welding thicker metals such as steel and aluminum, making it versatile for various industrial applications.

TIG Wire: Often preferred for thinner materials, including stainless steel and aluminum, due to its ability to control heat input more effectively.

5 - Ease of Use MIG Welding: Generally easier to learn, making it accessible for beginners.

The automated feeding mechanism reduces the complexity of the operation.

TIG Welding: Requires more skill and practice due to the need to manage both the tungsten electrode and filler material simultaneously.

This complexity can make it challenging for new welders.

Company Contact:

- Posted By: Hebei Machinery Import & Export Co.,Ltd.

- Phone: 18032253719

- Address: 181 Taihua St, Shijiazhuang Shi, Hebei Sheng, China

- Email:

- Website: https://www.sino-welding.com/

Published date: October 29, 2024

- Business Description: Hebei Machinery manufactory and export Welding Machinery, Welding Consumable and Welding Component for more than 20 years.

The products including Welding Electrodes Production Line, Welding Machine, Plasma Welding Machine, Cutting Machine, Welding Torch, Cutting Torch, Welding Wire, Welding Electrodes, and relative Welding products.

It is our great honor to satisfy your requirements on welding products.

Any requirement from you will be maximized by us.

Related listings

-

Ge Is230srtdh2a Terminal BoardElectrical equipment and components - Anonymous - China - October 29, 2024 - 12000.00 Dollar US$

Ge Is230srtdh2a Terminal BoardElectrical equipment and components - Anonymous - China - October 29, 2024 - 12000.00 Dollar US$GE IS230SRTDH2A Terminal Board DESCRIPTION The GE IS230SRTDH2A Terminal Board (or GE IS230SRTDH2A) is a high-performance, high-reliability redundancy module for a variety of industrial applications that require very high system availability. Through ...

-

Ge Is230tcish6c Din Rail I O ModuleElectrical equipment and components - Anonymous - China - October 29, 2024 - 12000.00 Dollar US$

Ge Is230tcish6c Din Rail I O ModuleElectrical equipment and components - Anonymous - China - October 29, 2024 - 12000.00 Dollar US$GE IS230TCISH6C DIN Rail I/O Module Product Overview The IS230TCISH6C module is an important part of GE Electric's IS230 series, which is designed for DIN rail mounting and is compact and powerful. The module can be used in a variety of industrial au...

-

Filter Element Rp8314f0339z Sf For Bangladesh Power SystemElectrical equipment and components - DONGFANG YOYIK (DEYANG) ENGNIEERING CO; LTD - China - October 28, 2024 - 385.00 Dollar US$

Filter Element Rp8314f0339z Sf For Bangladesh Power SystemElectrical equipment and components - DONGFANG YOYIK (DEYANG) ENGNIEERING CO; LTD - China - October 28, 2024 - 385.00 Dollar US$"filter element RP8314F0339Z-SF for Bangladesh power system Main: hydraulic machinery and components, hydroelectric generating units; coal-fired generating units; generating units; electrical and electronic products processing; mechanical parts proce...

Safe Trade Tips

- Ask for business references and check them

- Use a payment method that offers better protection for all such as Letters of credit and verified professional escrow services. Avoid payments in advance such as money transfers

- Verify their business via their local Chamber of Commerce

- Search the internet using their website address, their business name, their phone and fax numbers, and their email addresses to see if you can find any feedback about them.

- Get to know more about scams and fraud to avoid: Internet Crime Complaint Center - Consumer Financial Protection Bureau

- This site is never involved in any transaction, and does not handle payments, shipping, guarantee transactions, provide escrow services, or offer "buyer protection" or "seller certification"