Glucose Syrup Production Line Equipment Plant - China

price: 12036800.00 Dollar US$

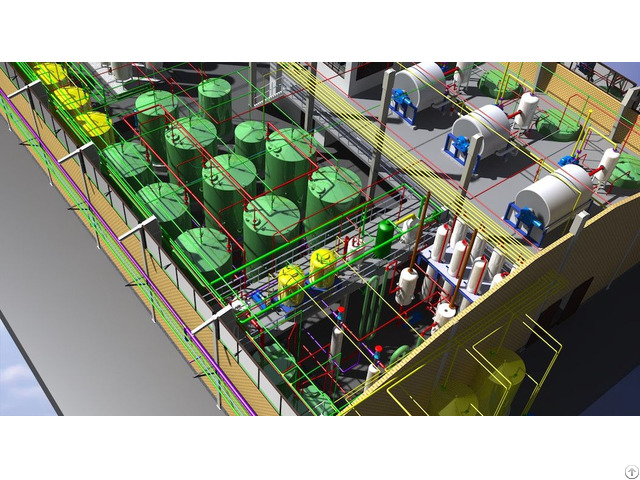

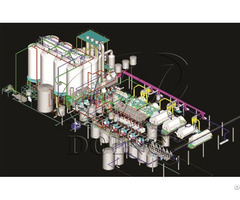

Glucose Syrup Production Line/Equipment/Plant Our production line 1 - Advanced and reliable glucose processing technology.

2 - Energy-saving, water-saving, labor-saving and little pollution.

hot recycling close type production and the process water will be recycled .

3 - Mostly machinery with fully stainless steel to be sure these is no corrosion.

4 - Advanced surface treatment craft.

Oil and dirty resisting.

5 - Many various capacity option from 0.5 tph to 20 tph.

Process description (1) Starch milk adjustment: Raw broken rice is unloaded to rice tank.

With water’s adding, it is sent to steeping tanks for softening.

Dipped rice is pumped to crashing stage, sending to rice storage after de-stone, de-iron and milling.

Starch milk coming from storage tank is adjusted to DS28-32% and proper PH and temperature.

(2) Liquefaction: Starch milk is sent to buffer tank then liquefied by jet cooker with the aid of liquefaction enzyme.

2 times jet cooking is needed for better reaction.

Then the material is sent to the flash for cooling then to the neutralization tank for suitable PH value.

(3) Rice gluten feed making: The mixed syrup goes to filter press for removing the protein residues, fiber, etc.

This dreg can be washed via process water to recover glucose.

Then it is sent to bundle dryer for gluten feed making.

(4) Saccharification: The temperature and PH value of liquefied material are adjusted and it is sent to saccharification tanks for reaction.

After being kept in saccharification tank, the required DE value of the glucose will be reached.

(5) Filtration and decoloring: Active carbon is needed for decoloring at proper temperature.

The active carbon will adsorb the color material from the glucose.

After that, the glucose and active carbon are sent to the filter press to filter the active carbon.

The cleaned glucose is sent to the next section.

(6) Ion exchange: Tiny foreign items and bad odor is removed via ion exchanger.

This equipment is used for high quality product.

(7) Evaporation: The glucose is totally cleaned through safety filter then sent to evaporator for concentrating to reach the required DS as final product.

Our team 1 - Strong and vigorous technological force member.

2 - Abundant theory and practical experience.

3 - The zealous service and fast reply.

4 - The scientific management system.

Company Contact:

- Posted By: Jiaozuo Doing Machanical Equipment Co., Ltd

- Phone: 0086 135 2661 5783

- Address: www.cassavaprocessingmach ine.com Zhengzhou,Henan,China, zhengzhou , Henan province, China

- Email:

Published date: September 25, 2017 - Modified date: September 25, 2017

- Business Description: Spontaneous research and development the following product:

cassava machine, cassava starch machine, cassva processing machine, cassava starch processing machine, gluten syrup machine from statch

Potato, sweet potato and cassava starch production plant

Glucose syrup & Maltose syrup processing plant

Corn syrup & high fructose processing plant

Air flow clash dyer

Drum rotary dehydration machine .

Related listings

-

Rice Glucose Syrup Processing MachineManufacturing technologies - Jiaozuo Doing Machanical Equipment Co., Ltd - China - September 25, 2017 - 10230000.00 Dollar US$

Rice Glucose Syrup Processing MachineManufacturing technologies - Jiaozuo Doing Machanical Equipment Co., Ltd - China - September 25, 2017 - 10230000.00 Dollar US$Description of rice glucose syrup processing machine (1) Starch milk adjustment: Raw broken rice is unloaded to rice tank. With water’s adding, it is sent to steeping tanks for softening. Dipped rice is pumped to crashing stage, sending to rice stora...

-

Cassava Starch PlantManufacturing technologies - Jiaozuo Doing Machanical Equipment Co., Ltd - China - September 18, 2017 - 223500.00 Dollar US$

Cassava Starch PlantManufacturing technologies - Jiaozuo Doing Machanical Equipment Co., Ltd - China - September 18, 2017 - 223500.00 Dollar US$Cassava starch plant producing pharmaceutical and food grade starch Cassava proliferates in tropical and sub tropical regions and will readily grow on marginal and low nutrient terrain. Cassava is grown throughout sub-Saharan Africa and is mostly use...

-

Stainless Steel Gluten WasherManufacturing technologies - Jiaozuo Doing Machanical Equipment Co., Ltd - China - September 18, 2017 - 8500.00 Dollar US$

Stainless Steel Gluten WasherManufacturing technologies - Jiaozuo Doing Machanical Equipment Co., Ltd - China - September 18, 2017 - 8500.00 Dollar US$Application of Stainless steel gluten washer 1.Wheat gluten production line 2.Wheat starch production line Brief Introduction of the Stainless steel gluten washer This Stainless steel gluten washer is the latest energy-saving equipment, is a professi...

Safe Trade Tips

- Ask for business references and check them

- Use a payment method that offers better protection for all such as Letters of credit and verified professional escrow services. Avoid payments in advance such as money transfers

- Verify their business via their local Chamber of Commerce

- Search the internet using their website address, their business name, their phone and fax numbers, and their email addresses to see if you can find any feedback about them.

- Get to know more about scams and fraud to avoid: Internet Crime Complaint Center - Consumer Financial Protection Bureau

- This site is never involved in any transaction, and does not handle payments, shipping, guarantee transactions, provide escrow services, or offer "buyer protection" or "seller certification"