Automatic Potato Starch Design Processing Production Line Making Machines With Good Quality - China

price: contact company for price

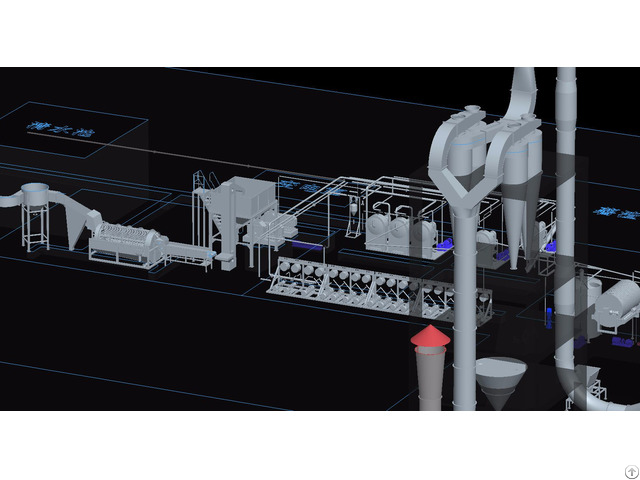

(1) Raw material receiving unit: The potato is carried besides the storage pool after weighing.

Firstly, it goes through the vibration sieve for removing the stones and sand.

Then the pre-cleaned potato falls on the belt conveyer and enters into the storage pool, and the rubbish will be carried away by truck.

(2) Water transport unit: The exit of the storage pool is water transportation channel.

The potato will be sent by water force into de-stone machine.

Meanwhile, the remaining sand and dirt will be again cleaned out by rolling and friction.

(3) De-stone and washing unit: Potato is transferred into the screw destone machine to be cleaned by water flow.

The small sand and stone go through the rotary screen then meet with bigger size stone which was stopped and sent back to the entrance of de-stone machine.

Most of sand and stone are removed out of de-stone machine.

The potato then goes into rotary cleaning machine for further removing of dirt and broken chips.

Cleaned potato falls on a checking conveying belt equipped with nozzles for washing the surface of potato.

Workers can manually take out the rotten potatos, wooden and plastic items.

At the end of belt, the iron remover is installed for removing metal impurities.

Then the potato is sent by bulk elevator into temporary storage in which it can stay 2 hours.

(4) Milling unit: The milling unit is the most important step for extracting potato starch.

The feeding screw combined at bottom of the storage tank pumped the clean potato into milling machine.

Highly-efficient milling machine will release the starch in potato at most.

(5) De-sanding cyclone unit: After milling, the starch milk is transferred to de-sanding cyclone by fiber pump.

The hydro-cyclone divide the milk into two parts: the light part which contains the mixture of starch and residue will go out from top of the cyclone, and the heavy part which contains the sand will be discharged out of the system.

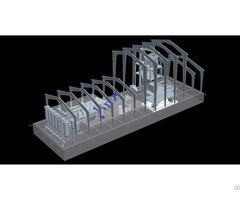

(6) Centrifugal extracting unit: The mixture is transferred to the 3 stage centrifugal sieves, each sieve works with a fiber pump and a defoam pump.

The mixture enters into each sieve to separate residue and starch.

After 3 stages continuous washing and separation, the filtrate is sent to concentration and refining unit, and the residue is sent to the residue dewatering unit.

(7) Potato residue dewatering unit: The potato residue will be pumped to the centrifugal sieve for dewatering, the centrifugal sieve works like the extraction sieve.

Then the screw conveyor discharges the residue out of the process, and the water will go back to the process water system.

(8) Concentration and refining unit

The starch milk from centrifugal sieve goes into the 16 stages of refining hydro-cyclone, and fresh water comes into the cyclone from the end of system.

Firstly, starch milk is pumped into 3 stages of concentration unit to remove the water, then the condensed starch milk enter the next 13 stages of washing unit, and the overflow enters into another 2 stages of recycle unit to recycle starch.

Most of the effluent with fiber is discharged out of the process, and a little part goes back to the process water system.

Finally, the condensed starch slurry is pumped into the starch slurry storage tank.

(9) Vacuum dewatering unit: The starch slurry is pumped into inlet tank of vacuum dewatering machine.

Then the vacuum rotary drum will adsorb the starch on the drum surface and the filtrate is transferred out of the system by filtrate pump.

The filter cake on the drum will be peeled off by peeler and then transferred to the air dryer by screw conveyor.

(10) Air drying unit: After dewatering process, the air dryer will dry the starch to the required moisture of the commercial starch.

Then starch goes into the screw conveyor.

(11) Sieving and storage unit: The starch is transferred into the vibration sieve by screw conveyor, and the sieve is used to separate the coarse and fine starch particle.

Then the fine starch goes into starch tank for temporary storage.

(12) Weighing and package unit: After seiving, the fine starch goes to the auto-packager, and will be packed into 25 kg/bag.

Company Contact:

- Posted By: Beijing Meckey Engineering Co.,LTD

- Phone: 86-010-87571743

- Address: Bldg.5-1511,Ronghua Xintai plaza,NO.10Ronghua South-Road,BDA, Beijing , Beijing , China

- Email:

- Website: https://www.meckey.com/en.html

Published date: May 28, 2018

- Business Description: Contact person: Pu Huang

Phone: 86-13282413454

Email: sales@meckey.

com

Website: http: //www.

meckey.

com/en.

html

Company Description:

Beijing MecKey Engineering Co.

is an innovation company committed to offering durable equipment and optimized solution in Agri-products processing industry.

Our equipment and processes have already been used in projects overseas, and it has been proven effective relying on our know-how and continuous technical processes development.

MecKey already has partners for offering technical and after-sales services in Iran and Russia as well as we are building service networks in Pakistan, India and other countries.

Related listings

-

Wheat Starch Flour Processing Project EngineeringIndustrial food and beverage equipment - Beijing Meckey Engineering Co.,LTD - China - May 28, 2018 - contact company for price

Wheat Starch Flour Processing Project EngineeringIndustrial food and beverage equipment - Beijing Meckey Engineering Co.,LTD - China - May 28, 2018 - contact company for pricewheat starch/flour processing project/engineering (1) Dough making: Flour is mixed with appropriate proportion water in mixer to form dough. After staying for set time in dough tank, dough enters into watering rotary drum. (2) Dough watering: Dough i...

-

Professional Wheat Starch Flour Design Processing Making Machines Advanced Production LineIndustrial food and beverage equipment - Beijing Meckey Engineering Co.,LTD - China - May 28, 2018 - contact company for price

Professional Wheat Starch Flour Design Processing Making Machines Advanced Production LineIndustrial food and beverage equipment - Beijing Meckey Engineering Co.,LTD - China - May 28, 2018 - contact company for price(1) Dough making: Flour is mixed with appropriate proportion water in mixer to form dough. After staying for set time in dough tank, dough enters into watering rotary drum. (2) Dough watering: Dough is washed by sufficient water being agitated by the...

-

Corn Starch Design Processsing Process Engineering Project SupplierIndustrial food and beverage equipment - Beijing Meckey Engineering Co.,LTD - China - May 28, 2018 - contact company for price

Corn Starch Design Processsing Process Engineering Project SupplierIndustrial food and beverage equipment - Beijing Meckey Engineering Co.,LTD - China - May 28, 2018 - contact company for priceCorn starch design/processsing/proces s engineering/project supplier (1) Purifying: Before going to storage bin, pre-purifying is done to eliminate big and small foreign substance, which will be sent to germ cake collection section. The rotary screen...

Safe Trade Tips

- Ask for business references and check them

- Use a payment method that offers better protection for all such as Letters of credit and verified professional escrow services. Avoid payments in advance such as money transfers

- Verify their business via their local Chamber of Commerce

- Search the internet using their website address, their business name, their phone and fax numbers, and their email addresses to see if you can find any feedback about them.

- Get to know more about scams and fraud to avoid: Internet Crime Complaint Center - Consumer Financial Protection Bureau

- This site is never involved in any transaction, and does not handle payments, shipping, guarantee transactions, provide escrow services, or offer "buyer protection" or "seller certification"