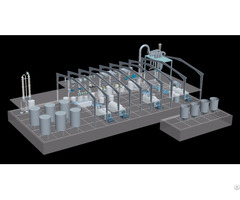

Corn Starch Design Processsing Process Engineering Project Supplier - China

price: contact company for price

Corn starch design/processsing/proces s engineering/project supplier

(1) Purifying: Before going to storage bin, pre-purifying is done to eliminate big and small foreign substance, which will be sent to germ cake collection section.

The rotary screen placed beside the storage bin, has de-stoning and de-dusting functions.

Purified corn is then sent to steeping section.

(2) Steeping: Counter current steeping principle is adopted to make corn become soft in steeping tank.

Acid is heated and remains about 50℃ when circulating in all tanks.

Dipped corn is pumped to crashing stage.

(3) Sulfurous acid making: Sulfur is burned in furnace, getting SO2 gas, goes to absorbtion tower with china rings.

Water is sprayed down, mixed with rising SO2 gas to get sulfurous acid.

(4) Crash and germ separation: Steeped corn is sent to 1st germ mill from wet corn storage bin.

Crashed corn is pumped into 1st germ cyclone and screen to separate, and then goes to 2nd mill for further crush.

Germ goes to 2nd germ cyclone, and then the light will be back to previous tank.

(5) Finely milling and fiber wash, dewater, drying: In pin mill, the degermed corn is multi--strongly crashed to remove fiber off.

Fiber is sent to multi-stage washing screen for recovering the balance starch.

Cleaned fiber goes to squeezer for dewatering then goes into bundle dryer for drying to mix with corn slurry for making animal feed product.

(6) Protein separation and starch washing: Starch milk goes to primary separator for gluten separation.

Cleaned starch goes to 12 stages hydro cyclones for final washing to remove the tiny foreign items.

(7) Starch dewater and drying: Fine starch milk is dewatered by peeler centrifuge, the starch is sent to air flow dryer for making dry starch product in which moisture should be less than 14%.

The finishing product is wrapped up through the packer and shipped out.

(8) Germ washing, dewater, drying, extraction oil and oil refinery: Germs from cyclone go to gravity arc screen for washing, then to squeezer for dewatering.

Washed germs are sent to bundle dryer.

Dried germ is fried and extracted then oil is filtered.

Coarse oil is gotten at the end.

(9) Gluten concentration, dewater, drying: Gluten is concentrated by air floating vessels then goes to vacuum filter for further dewatering.

Dewatered gluten goes to bundle dryer for making gluten meal product.

Company Contact:

- Posted By: Beijing Meckey Engineering Co.,LTD

- Phone: 86-010-87571743

- Address: Bldg.5-1511,Ronghua Xintai plaza,NO.10Ronghua South-Road,BDA, Beijing , Beijing , China

- Email:

- Website: https://www.meckey.com/en.html

Published date: May 28, 2018

- Business Description: Contact person: Pu Huang

Phone: 86-13282413454

Email: sales@meckey.

com

Website: http: //www.

meckey.

com/en.

html

Company Description:

Beijing MecKey Engineering Co.

is an innovation company committed to offering durable equipment and optimized solution in Agri-products processing industry.

Our equipment and processes have already been used in projects overseas, and it has been proven effective relying on our know-how and continuous technical processes development.

MecKey already has partners for offering technical and after-sales services in Iran and Russia as well as we are building service networks in Pakistan, India and other countries.

Related listings

-

Full Automatic Corn Starch Design Processsing Process Production Making Line MachinesIndustrial food and beverage equipment - Beijing Meckey Engineering Co.,LTD - China - May 28, 2018 - contact company for price

Full Automatic Corn Starch Design Processsing Process Production Making Line MachinesIndustrial food and beverage equipment - Beijing Meckey Engineering Co.,LTD - China - May 28, 2018 - contact company for price(1) Purifying: Before going to storage bin, pre-purifying is done to eliminate big and small foreign substance, which will be sent to germ cake collection section. The rotary screen placed beside the storage bin, has de-stoning and de-dusting functio...

-

Debao 1250s Paper Bowl Forming MachineIndustrial food and beverage equipment - Zhejiang New Debao Machinery Co.,Ltd. - China - May 18, 2018 - check with company for price

Debao 1250s Paper Bowl Forming MachineIndustrial food and beverage equipment - Zhejiang New Debao Machinery Co.,Ltd. - China - May 18, 2018 - check with company for price1.This machine using desktop layout, the mold and the transmission part are isolated, which is easy to clean. 2.automatic spray lubrication 3.PLC is used to control the whole electrical, photoelectric tracking and monitoring. 4.servo feeding weight:3...

-

China Coconut Shell Grinder Machine PriceIndustrial food and beverage equipment - Henan Lantian Machinery Manufacturing Co., Ltd. - China - May 18, 2018 - 854.00 Dollar US$

China Coconut Shell Grinder Machine PriceIndustrial food and beverage equipment - Henan Lantian Machinery Manufacturing Co., Ltd. - China - May 18, 2018 - 854.00 Dollar US$Brief introduction of coconut shell grinder machine: Lantian series wood crusher can crush different raw materials, such as charcoal, hardwood, softwood, branch, chips, coconut shell, bamboo, sawdust, etc. If charcoal, the finished powder can be 80me...

Safe Trade Tips

- Ask for business references and check them

- Use a payment method that offers better protection for all such as Letters of credit and verified professional escrow services. Avoid payments in advance such as money transfers

- Verify their business via their local Chamber of Commerce

- Search the internet using their website address, their business name, their phone and fax numbers, and their email addresses to see if you can find any feedback about them.

- Get to know more about scams and fraud to avoid: Internet Crime Complaint Center - Consumer Financial Protection Bureau

- This site is never involved in any transaction, and does not handle payments, shipping, guarantee transactions, provide escrow services, or offer "buyer protection" or "seller certification"