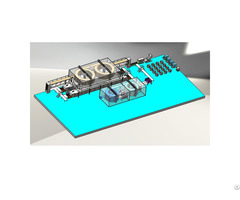

Spiral Cooling Conveyor - China

price: check with company for price

Introduction:

This machine is equipped with layer by layer transmission technology which is similar to European technology.

The gear motor drives the gear on every layer through a spindles, and the gear stir the convey belt for movement.

Every gear has intelligent power transmitter which can adjust the convey power.

Features:

1 - Double side nylon card track is stable when it is in operation, it will never get stucked or upturning.

2 - Every belt can adjust the power automatically and keep the power equal because it has intelligent transmission technology.

And its speed is Variable.

3 - We choose high strength nylon card track and low friction food grade pp guide rail for it.

And it has automatic lubrication system so you do not need to add lubricating oil and no need to repair or change any components within many years.

4 - We can design different Input and output directions according to customer;s workshop’s area, such as low input and high output, high input and low output, two input and two output, three input and three output, the last kind is elliptic type.

5 - It saves spaces and guaranteeing high efficiency.

6 - Adapted to bakery products, vegetables, fruit, meat and fish etc.

7 - The convey belt is stainless steel 304 - To grantee it is durable, the frame is ss304 or ss201 square steel tube.

8 - Equip with automatic cleaning device and will do the cleaning automatically.

There are some food scraps and stain during the operation of the tower, our engineers invent automatic cleaning device which can finish cleaning work within 1-2 hours and also dry it automatically.

We have three kinds: single tower, double towers, elliptic tower.

9 - It has variable-frequence, gear motor and Germany Schnelder Electric components.

10 - Belt convey can be bends, slopes or spirals.

It is customized for the following elements:

1 - Material, length and width of the conveyor belt.

2 - The height, diameter and layers quantity of the tower.

3 - In feed and out feed direction.

4 - Shape of the tower (round, elliptic).

5 - Material of the frame.

6 - The brand of the reduction motor, bearing, and the Inverter frequency device and screen.

Working Principle:

The Main Spindle drives per gear in each layer, and gears drives per mesh belt in each layer, so that the power of gear motor to be transmitted.

Each gear has smart power transmission device to adjust the transmission power automatically.

Characteristics of Spiral Cooling/Freezing Tower(transmit layer by layer):

1 - Nylon card rail in both sides are stable, without machine jams or upturning fault.

2 - Due to its intelligent transmission technology, the mesh belt in each layer can adjust its tension automatically, keep the transmission force in each layer equal.

3 - Adopts high strength Nylon card rail and low friction PP guide rail, resulting in lubricant in rotating unnecessary, scraps caused by friction not to drop or pollute food.

4 - Food input and output directions to be customized according to customer's workshop layout, such as Input in Lower entrance, well come out from higher exit, Input in Higher entrance, well Output from Lower exit, Twin Inputs+Twin Outputs, Three Inputs+Three Outputs, Round Circle or Ellipse Spiral Towers.

Proofer

It can be used as spiral proofer, assembly with production line, which improves the production efficiency greatly, users can monitor all proof process via computer control system.

Optional Device: Steam System and Heating System.

The Spiral Cooling/Freezing Tower is suitable for bulk and packaged foods.

It runs as usual at a temperature of 40 ºC below.

Deep freezer

* Deep-Freezing Spiral Tower designed according to usage of foods.

* Cooling/Freezing Settlement customize for bread, pizza, dumplings, wonton, fresh vegetable, fish or other meat.

Cooling

Suitable for cooling all kinds of baking foods and fried foods.

there are two types: Natrual cooling & Controlled Freezing.

Mesh belt to be customized, narrowed to be 200mm, widest to be 1300mm, Spiral tower, shortest to be 50m, longest to be 1200m.

The largest diameter of Spiral Tower to be 12m, shortest to be 1.5m.

The largest Spiral Tower height to be 6m, 40 layers at most.

Company Contact:

- Posted By: Hebei AOCNO Baking Machiney CO., LTD

- Phone: +8631168032934

- Address: No.19,Jingwu Road,Anping County,Hebei,China, Hengshui , Anping , China

- Email:

- Website: https://www.aocno.com

Published date: June 20, 2019

- Business Description: Hebei AOCNO Baking Machinery CO.,LTD, founded in May 1994,covers 95 acres building area.

We have modern plant, area up to 45,000 square meters and also an Integrity Building, 5,000 square meters, which active for R&D Center, Products Exhibition and Marketing Center and other facility.

We have self-support right of import and export, with approval of ISO9000 International Quality Assurance System and has already registered our AOCNO trademark in 5 countries in the world.

Now we have totally 195 staff, including 15 senior technical staff, 19 senior technical staff and 80 after sale stuff and 12 offices within the whole countries.

AOCNO Baking Machinery are highly cost-effective, our products such as dough mixer, oven, Spiral cooling tower, bakery equipment, bakery machinery, hamburger line, toast line, bakery line, cake line, food cooler, baking oven are not only popular with domestic markets, but also has gained good reputation from South Asia, East Asia, America, Australia, East European, Africa and other in over 50 countries.

Our Motto: Where there are people eating bread, there are AOCNO with excellent Device and services!

Related listings

-

Bread Tunnel OvenIndustrial food and beverage equipment - Hebei AOCNO Baking Machiney CO., LTD - China - June 20, 2019 - check with company for price

Bread Tunnel OvenIndustrial food and beverage equipment - Hebei AOCNO Baking Machiney CO., LTD - China - June 20, 2019 - check with company for priceAn oven can be ordered and designed: 1. The usage of the tunnel oven: Suitable for loaf bread, buns, baguette, croissant, cakes, pita bread, arabic bread, bagel, tortilla, mamoul, panko etc. 2. The advantage of proportion of zero-pressure gas-fired t...

-

Toast Making MachineIndustrial food and beverage equipment - Hebei AOCNO Baking Machiney CO., LTD - China - June 20, 2019 - check with company for price

Toast Making MachineIndustrial food and beverage equipment - Hebei AOCNO Baking Machiney CO., LTD - China - June 20, 2019 - check with company for priceIt is the automatic full continuous bread production line and with about 2-3 people is ok for operation. You Just provide how many bread do you make one hour and we will make the layout and quotation for you. Packaging & Delivery Packaging Detail...

-

Hamburger Making MachineIndustrial food and beverage equipment - Hebei AOCNO Baking Machiney CO., LTD - China - June 20, 2019 - check with company for price

Hamburger Making MachineIndustrial food and beverage equipment - Hebei AOCNO Baking Machiney CO., LTD - China - June 20, 2019 - check with company for priceIt is the automatic full continuous bread production line and with about 2-3 people is ok for operation. You Just provide how many bread do you make one hour and we will make the layout and quotation for you. Packaging & Delivery Packaging Detail...

Safe Trade Tips

- Ask for business references and check them

- Use a payment method that offers better protection for all such as Letters of credit and verified professional escrow services. Avoid payments in advance such as money transfers

- Verify their business via their local Chamber of Commerce

- Search the internet using their website address, their business name, their phone and fax numbers, and their email addresses to see if you can find any feedback about them.

- Get to know more about scams and fraud to avoid: Internet Crime Complaint Center - Consumer Financial Protection Bureau

- This site is never involved in any transaction, and does not handle payments, shipping, guarantee transactions, provide escrow services, or offer "buyer protection" or "seller certification"