Lag S400 Infrared Converter Slag Detection System - China

price: 5000.00 Dollar US$

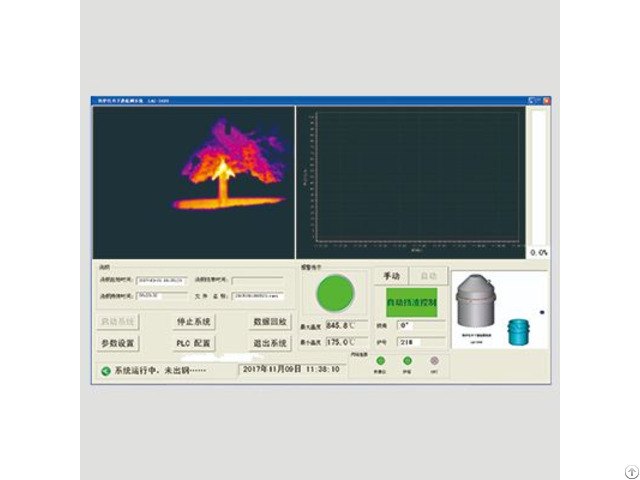

LAG-S400 Infrared Converter Slag Detection System Overview The infrared converter slag detection system uses a far-infrared thermal imager to monitor the situation of converter tapping in real time, and is connected to the main control computer in the electrical room through the conversion and transmission of video signals.

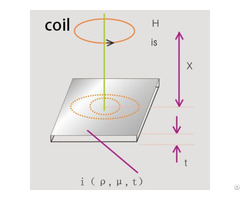

The radiation intensity in the infrared wavelength range of 7-14um is different to distinguish molten steel and slag.

In the later stage of the converter tapping, the molten steel gradually decreases, and the steelmaking slag is involved in the molten steel and flows out of the tapping hole.

After the thermal imager recognizes the steelmaking slag in the imaging temperature measurement, it will give an alarm according to the slag content ratio threshold set by the software.

The thermal imager will start the slide plate to close the tapping hole, so as to realize the control of the slag in the converter tapping, and ensure the maximum yield of molten steel and the minimum control of the steelmaking slag content.

The effect of slag detection in converter tapping is of great significance to the control effect of the slag amount.

The converter slag detection and control system developed by our company conducts non-contact monitoring of the tapping steel flow through the far-infrared detector thermal imager.

It can detect the slag condition in real time and output an alarm signal and control system, which can replace manual visual inspection and provide accurate, efficient and stable slag detection effect.

When the system finds the slag, the intelligent control unit quickly makes a judgment of lifting the furnace and blocking the slag and outputs an alarm signal.

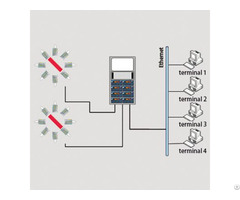

As shown in Figure 1, the system includes thermal imager, front purge protection box, front electrical box, power distribution cabinet, main control monitor, monitor of rocking furnace chamber, sound and light alarm, infrared converter slag monitoring software system, etc.

The features of thermal imager 1 - The temperature measurement range is -20°C - 2000°C, high temperature measurement accuracy, and multiple temperature measurement intervals can be set.

2 - High-resolution thermal imaging system, the imaging picture is clear, and the imaging color can be freely marked according to the set temperature.

3 - With hot zone alarm function, the alarm zone and temperature range can be set arbitrarily.

4 - With hot zone tracking function 5 - Equipped with special 7~14um infrared filter lens The technical parameters 1 - Temperature measurement range: 200-1800℃ 2 - Temperature measurement accuracy: 2% 3 - Detection accuracy and alarm accuracy: ≥98% 4 - Resolution: ≥ 0.5℃ 5 - Pixels: 640x240 6 - Band: 7~14um 7 - Field of view: 7.5°×5.5° 8 - Frame rate: ≥ 25 frames/sec 9 - Equipment service life: ≥5 years 10 - The normal operation rate of the automatic control system: ≥99%

Company Contact:

- Posted By: Wuhan CenterRise M&C Engineering CO., Ltd.

- Phone: 13995588597

- Address: Building 4, Hengxin Industrial Park, No. 8 Xinhua Avenue, Huangpi District, Wuhan , Hubei , China

- Email:

Published date: September 15, 2022

- Business Description: Wuhan CenterRise M&C Engineering Co., Ltd. is a high-tech enterprise specializing in automation products and engineering.

Our business scope includes the research and development, production and sales of automation systems, devices and various instruments.

We are a comprehensive automation company that designs, implements control systems and provides comprehensive automation systems and process control solutions.

Our company has a high-quality design and R&D team and a professional machining factory, with mature high-tech products and strong technical development and engineering strength, accumulated rich experience in the integration of industrial control systems and information systems.

Our company also cooperates closely with domestic and foreign universities and research institutes.

After years of steady and healthy development, in the fields of industrial automation, building intelligence, and network information, a high-tech enterprise development model has been formed which integrates development and design, system integration, engineering implementation, and complete equipment .

Our company focuses on the research and development of metallurgical measurement and control and automation products, and is committed to the research on key measurement and control of iron and steel metallurgical process automation.

The company's metallurgical measurement and control products cover the entire process of cokemaking, sintering, ironmaking, steelmaking, continuous casting, and steel rolling, and are widely used in major steel mills in China.

In the field of dedicated control, the company develops a series of measurement and control products for related processes, which can independently realize dedicated measurement and control, and can be seamlessly connected with basic automation systems and process automation systems.

It can provide users with comprehensive solutions for system measurement and control and automation.

Related listings

-

Ldc X200 Laser Diameter Measuring SystemIndustrial machine tools - Wuhan CenterRise M&C Engineering CO., Ltd. - China - September 15, 2022 - 5000.00 Dollar US$

Ldc X200 Laser Diameter Measuring SystemIndustrial machine tools - Wuhan CenterRise M&C Engineering CO., Ltd. - China - September 15, 2022 - 5000.00 Dollar US$LDC-X200 Laser Diameter Measurement System Overview The non-contact diameter measuring system, is mainly used in the measurement of the outer diameter of various wire rods, bars, wires and pipes. The system can detect the change of the diameter (oute...

-

Wgs L020 Flat Steel Ribbon Iron Width Measuring SystemIndustrial machine tools - Wuhan CenterRise M&C Engineering CO., Ltd. - China - September 15, 2022 - 5000.00 Dollar US$

Wgs L020 Flat Steel Ribbon Iron Width Measuring SystemIndustrial machine tools - Wuhan CenterRise M&C Engineering CO., Ltd. - China - September 15, 2022 - 5000.00 Dollar US$WGS-L020 Flat Steel/Ribbon Iron Width Measuring System Overview Whether the width and thickness of the flat steel/ribbon iron width measurement device can meet the standard in the production process directly determines the quality of the flat steel/r...

-

Mlc V235 Continuous Casting Mold Level Automatic Measurement SystemIndustrial machine tools - Wuhan CenterRise M&C Engineering CO., Ltd. - China - September 15, 2022 - 5000.00 Dollar US$

Mlc V235 Continuous Casting Mold Level Automatic Measurement SystemIndustrial machine tools - Wuhan CenterRise M&C Engineering CO., Ltd. - China - September 15, 2022 - 5000.00 Dollar US$MLC-V235 Continuous Casting Mold Level Automatic Measurement System Overview The automatic control for the molten steel level of the mold is one of the key technologies of continuous casting production. It is very important to reduce the labor intens...

Safe Trade Tips

- Ask for business references and check them

- Use a payment method that offers better protection for all such as Letters of credit and verified professional escrow services. Avoid payments in advance such as money transfers

- Verify their business via their local Chamber of Commerce

- Search the internet using their website address, their business name, their phone and fax numbers, and their email addresses to see if you can find any feedback about them.

- Get to know more about scams and fraud to avoid: Internet Crime Complaint Center - Consumer Financial Protection Bureau

- This site is never involved in any transaction, and does not handle payments, shipping, guarantee transactions, provide escrow services, or offer "buyer protection" or "seller certification"