Ldc X200 Laser Diameter Measuring System - China

price: 5000.00 Dollar US$

LDC-X200 Laser Diameter Measurement System Overview The non-contact diameter measuring system, is mainly used in the measurement of the outer diameter of various wire rods, bars, wires and pipes.

The system can detect the change of the diameter (outer diameter) of the measured object in real time under the high temperature state.

The working principle The diameter measuring system takes the laser scanning method as an example.

It adopts the probe imported from Japan, which can achieve an accuracy of plus or minus 2 microns in the range of 0.3 to 30 mm.

The acquisition frequency reaches 2000 times/second.

The probe uses a self-excited infrared light source, which overcomes the measurement problem in dim environments.

It adopts the measurement method of pulse parallel light scanning, and has a strong ability to resist the jitter of the measured object.

(As shown in Figure 1) Since the shaking frequency of the measured object is much smaller than the scanning frequency, when the measured object A moves in the shakeable area, the measurement result will be able to ensure its accuracy because the time it blocks the beam does not change.

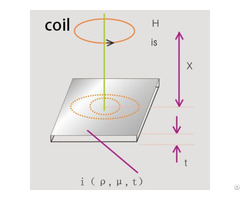

First, the crystal oscillator generates self-excited high-frequency pulses, which are sent to the comparator and the stepping servo motor respectively.

The stepping servo motor drives the octahedral prism to rotate at a high speed, and reflects the infrared laser emitted by the laser generator to the convex lens A.

It becomes parallel light, and then collects on the photosensitive element C through the convex lens B in the infrared receiving probe.

The photosensitive element C converts this signal into a corresponding electrical signal and sends it to the other end of the comparator to compare with the original signal.

When there is no object to be measured in the measuring probe, the pulse signal at both ends of the comparator will be the same.

Therefore, there is no difference output: when there is an object to be measured in the measuring probe, the photosensitive element C will output no pulse signal during the period of scanning through the object to be measured.

Therefore, there will be a difference input for a period of time at both ends of the comparator, which corresponds to the diameter of the measured object.

By calculating the oscillation period of the pulse and the length of the time slice without pulse, the diameter of the measured object can be known.

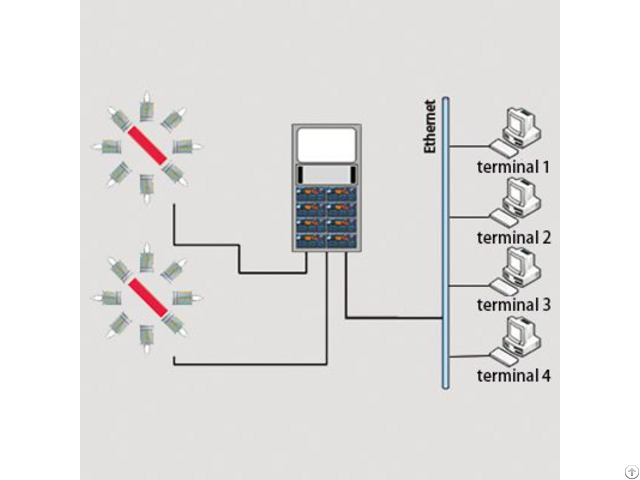

The system consists of the following main parts (as shown in Figure 1) 1 - A measurement frame with four pairs of high-frequency laser scanning probes and non-contact infrared thermometers is installed 2 - Four intelligent signal processors connected with four pairs of high frequency laser scanning probes 3 - Cold air blowing system for cooling and cleaning the measuring frame 4 - High-performance intelligent controller responsible for front-end data signal processing and network communication 5 - Data processing and analysis system installed with industrial grade PC, monitor and printer

Company Contact:

- Posted By: Wuhan CenterRise M&C Engineering CO., Ltd.

- Phone: 13995588597

- Address: Building 4, Hengxin Industrial Park, No. 8 Xinhua Avenue, Huangpi District, Wuhan , Hubei , China

- Email:

Published date: September 15, 2022

- Business Description: Wuhan CenterRise M&C Engineering Co., Ltd. is a high-tech enterprise specializing in automation products and engineering.

Our business scope includes the research and development, production and sales of automation systems, devices and various instruments.

We are a comprehensive automation company that designs, implements control systems and provides comprehensive automation systems and process control solutions.

Our company has a high-quality design and R&D team and a professional machining factory, with mature high-tech products and strong technical development and engineering strength, accumulated rich experience in the integration of industrial control systems and information systems.

Our company also cooperates closely with domestic and foreign universities and research institutes.

After years of steady and healthy development, in the fields of industrial automation, building intelligence, and network information, a high-tech enterprise development model has been formed which integrates development and design, system integration, engineering implementation, and complete equipment .

Our company focuses on the research and development of metallurgical measurement and control and automation products, and is committed to the research on key measurement and control of iron and steel metallurgical process automation.

The company's metallurgical measurement and control products cover the entire process of cokemaking, sintering, ironmaking, steelmaking, continuous casting, and steel rolling, and are widely used in major steel mills in China.

In the field of dedicated control, the company develops a series of measurement and control products for related processes, which can independently realize dedicated measurement and control, and can be seamlessly connected with basic automation systems and process automation systems.

It can provide users with comprehensive solutions for system measurement and control and automation.

Related listings

-

Wgs L020 Flat Steel Ribbon Iron Width Measuring SystemIndustrial machine tools - Wuhan CenterRise M&C Engineering CO., Ltd. - China - September 15, 2022 - 5000.00 Dollar US$

Wgs L020 Flat Steel Ribbon Iron Width Measuring SystemIndustrial machine tools - Wuhan CenterRise M&C Engineering CO., Ltd. - China - September 15, 2022 - 5000.00 Dollar US$WGS-L020 Flat Steel/Ribbon Iron Width Measuring System Overview Whether the width and thickness of the flat steel/ribbon iron width measurement device can meet the standard in the production process directly determines the quality of the flat steel/r...

-

Mlc V235 Continuous Casting Mold Level Automatic Measurement SystemIndustrial machine tools - Wuhan CenterRise M&C Engineering CO., Ltd. - China - September 15, 2022 - 5000.00 Dollar US$

Mlc V235 Continuous Casting Mold Level Automatic Measurement SystemIndustrial machine tools - Wuhan CenterRise M&C Engineering CO., Ltd. - China - September 15, 2022 - 5000.00 Dollar US$MLC-V235 Continuous Casting Mold Level Automatic Measurement System Overview The automatic control for the molten steel level of the mold is one of the key technologies of continuous casting production. It is very important to reduce the labor intens...

-

Mac G320 Automatic Mold Flux Feeding MachineIndustrial machine tools - Wuhan CenterRise M&C Engineering CO., Ltd. - China - September 15, 2022 - 5000.00 Dollar US$

Mac G320 Automatic Mold Flux Feeding MachineIndustrial machine tools - Wuhan CenterRise M&C Engineering CO., Ltd. - China - September 15, 2022 - 5000.00 Dollar US$MAC-G320 Automatic Mold Flux Feeding Machine Overview MAC-G320 automatic mold flux feeding system is a new generation product of automatic adding mold flux, which is independently developed by Wuhan CenterRise M&C Engineering Co., Ltd. According ...

Safe Trade Tips

- Ask for business references and check them

- Use a payment method that offers better protection for all such as Letters of credit and verified professional escrow services. Avoid payments in advance such as money transfers

- Verify their business via their local Chamber of Commerce

- Search the internet using their website address, their business name, their phone and fax numbers, and their email addresses to see if you can find any feedback about them.

- Get to know more about scams and fraud to avoid: Internet Crime Complaint Center - Consumer Financial Protection Bureau

- This site is never involved in any transaction, and does not handle payments, shipping, guarantee transactions, provide escrow services, or offer "buyer protection" or "seller certification"