Mlc V235 Continuous Casting Mold Level Automatic Measurement System - China

price: 5000.00 Dollar US$

MLC-V235 Continuous Casting Mold Level Automatic Measurement System Overview The automatic control for the molten steel level of the mold is one of the key technologies of continuous casting production.

It is very important to reduce the labor intensity of workers, improve production efficiency, improve the quality and output of casting billet, reduce overflow and breakout of steel and improve the management level of steelmaking and continuous casting.

The molten steel is poured into the mold.

In order to prevent overflow, the molten steel level must be kept stable.

Otherwise, during the casting process, if the level will fluctuate too much, and slag will be involved, forming surface slag inclusion on the surface of the casting billet, affecting the quality of the billet.

The test points out that the relationship between the level fluctuation and the depth of casting billet surface slag inclusion is as follows: The experience has shown that surface slag inclusions can be eliminated when the level fluctuation is within ±10mm.

At the same time, if the level fluctuation is more than 10mm, the rate of longitudinal cracks on the casting billet surface is 30%.

It means that the level fluctuation directly affects the surface quality of the casting billet.

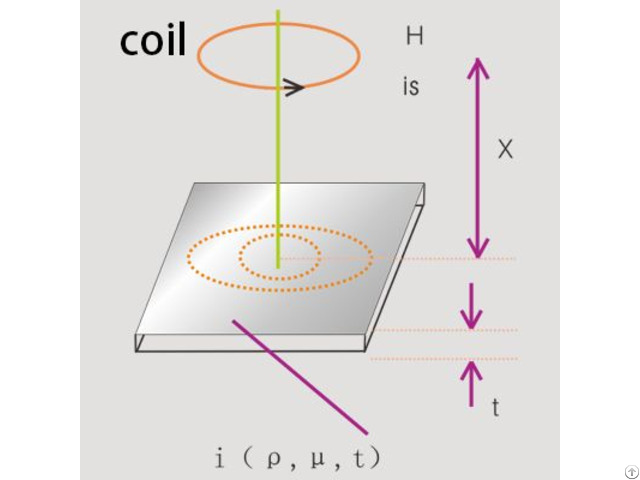

The principle of the system The eddy current type molten steel level gauge is the key to the system.

The system operates reliably and has excellent performance: high temperature resistance, strong anti-interference ability, fast dynamic response (lag time <0.10s), high detection accuracy (<±05mm), and large measurement range (0-150mm).

The selected electromagnetic field frequency ensures that the level detection probe only detects the level change of the mold and does not detect the mold flux or steel slag layer.

The system has the advantages of simple operation and no radiation protection problems.

The system is insensitive to argon blowing, and its sensors can be mounted on the tundish car or on the platform.

The sensor is cooled by compressed air during use.

The components of the system Continuous casting mold level automatic control system is composed of eddy current tyoe molten steel level gauge, controller and digital actuator for adjusting the opening of tundish stopper.

The detection end of the mold level automatic control system is ① eddy current displacement sensor, which uses the eddy current mutual inductance effect between the energized coil and the metal conductor to detect the distance.

The effective signal of the eddy current sensor is amplified and linearized by the circuit of ② mold level gauge, which converts the 0-150mm change in the molten steel level of the mold into a standard signal of 4-20mA.

DC, and then transmits it to the ③ control computer to complete data processing and system control functions.

We can also control the actuator manually and automatically through the ④on-site operation display control panel, and the opening of the stopper is controlled by the ⑤ actuator to realize the automatic control of the molten steel level.

1 Eddy current sensor; 2 mold level gauge; 3 control computer; 4 On-site operation display control panel; 5 digital actuator; The function and software implementation In order to overcome these disturbances, the mold level control strategy adopts PID control.

And on the basis of PID control, self-adaptive correction and feedforward control are introduced to form an advanced control system.

The level control is the main loop, and there is a proportional gain of the main loop controller.

According to the self-adaptive correction of the mold width change and feedforward compensation of casting speed, so as to further reduce and eliminate liquid level fluctuations caused by mold width adjustment and casting speed changes.

In order to reduce the frequent action of the stopper, the system adopts the intergarting time change of the controller, and automatically selects a longer intergarting time when the molten steel level fluctuates lightly.

And the system will choose a shorter intergrating time when molten steel level fluctuates greatly.

Thereby, the fluctuation of the controlled object caused by the frequent action of the stopper rod is suppressed.

In the signal processing of molten steel level gauge, an appropriate filtering link is added and the vibration frequency synchronous filter is used for filtering processing, which can overcome the interference of mold vibration frequency and amplitude variation.

Company Contact:

- Posted By: Wuhan CenterRise M&C Engineering CO., Ltd.

- Phone: 13995588597

- Address: Building 4, Hengxin Industrial Park, No. 8 Xinhua Avenue, Huangpi District, Wuhan , Hubei , China

- Email:

Published date: September 15, 2022

- Business Description: Wuhan CenterRise M&C Engineering Co., Ltd. is a high-tech enterprise specializing in automation products and engineering.

Our business scope includes the research and development, production and sales of automation systems, devices and various instruments.

We are a comprehensive automation company that designs, implements control systems and provides comprehensive automation systems and process control solutions.

Our company has a high-quality design and R&D team and a professional machining factory, with mature high-tech products and strong technical development and engineering strength, accumulated rich experience in the integration of industrial control systems and information systems.

Our company also cooperates closely with domestic and foreign universities and research institutes.

After years of steady and healthy development, in the fields of industrial automation, building intelligence, and network information, a high-tech enterprise development model has been formed which integrates development and design, system integration, engineering implementation, and complete equipment .

Our company focuses on the research and development of metallurgical measurement and control and automation products, and is committed to the research on key measurement and control of iron and steel metallurgical process automation.

The company's metallurgical measurement and control products cover the entire process of cokemaking, sintering, ironmaking, steelmaking, continuous casting, and steel rolling, and are widely used in major steel mills in China.

In the field of dedicated control, the company develops a series of measurement and control products for related processes, which can independently realize dedicated measurement and control, and can be seamlessly connected with basic automation systems and process automation systems.

It can provide users with comprehensive solutions for system measurement and control and automation.

Related listings

-

Mac G320 Automatic Mold Flux Feeding MachineIndustrial machine tools - Wuhan CenterRise M&C Engineering CO., Ltd. - China - September 15, 2022 - 5000.00 Dollar US$

Mac G320 Automatic Mold Flux Feeding MachineIndustrial machine tools - Wuhan CenterRise M&C Engineering CO., Ltd. - China - September 15, 2022 - 5000.00 Dollar US$MAC-G320 Automatic Mold Flux Feeding Machine Overview MAC-G320 automatic mold flux feeding system is a new generation product of automatic adding mold flux, which is independently developed by Wuhan CenterRise M&C Engineering Co., Ltd. According ...

-

Moc K100 Mould Online Oscillation Monitoring SystemIndustrial machine tools - Wuhan CenterRise M&C Engineering CO., Ltd. - China - September 14, 2022 - 5000.00 Dollar US$

Moc K100 Mould Online Oscillation Monitoring SystemIndustrial machine tools - Wuhan CenterRise M&C Engineering CO., Ltd. - China - September 14, 2022 - 5000.00 Dollar US$MOC-K100 Mould Online Oscillation Monitoring System Overview Mold is the casting billet forming equipment in continuous steel casting, and it is also the core equipment and key technology of continuous casting machine. Its function is to forcibly coo...

-

Zsq T100 Online Surface Quality Inspection System For Casting Billet Eddy CurrentIndustrial machine tools - Wuhan CenterRise M&C Engineering CO., Ltd. - China - September 14, 2022 - 5000.00 Dollar US$

Zsq T100 Online Surface Quality Inspection System For Casting Billet Eddy CurrentIndustrial machine tools - Wuhan CenterRise M&C Engineering CO., Ltd. - China - September 14, 2022 - 5000.00 Dollar US$ZSQ-T100 Online Surface Quality Inspection System for Casting Billet (Eddy Current) The principle of the system The ZSQ-T100 online surface quality inspection system for casting billet adopts the principle of eddy current non-destructive testing. Acc...

Safe Trade Tips

- Ask for business references and check them

- Use a payment method that offers better protection for all such as Letters of credit and verified professional escrow services. Avoid payments in advance such as money transfers

- Verify their business via their local Chamber of Commerce

- Search the internet using their website address, their business name, their phone and fax numbers, and their email addresses to see if you can find any feedback about them.

- Get to know more about scams and fraud to avoid: Internet Crime Complaint Center - Consumer Financial Protection Bureau

- This site is never involved in any transaction, and does not handle payments, shipping, guarantee transactions, provide escrow services, or offer "buyer protection" or "seller certification"