Mould Online Width Adjustment And Taper Measurement - China

price: 5000.00 Dollar US$

Mould Online Width Adjustment and Taper Measurement Overview In order to meet the needs of producing various specifications of continuously cast products, shorten the time for replacing the mold, and improve the production capacity and production efficiency of the continuous casting machine, the mold online width adjustment system is the key technology for efficient continuous casting.

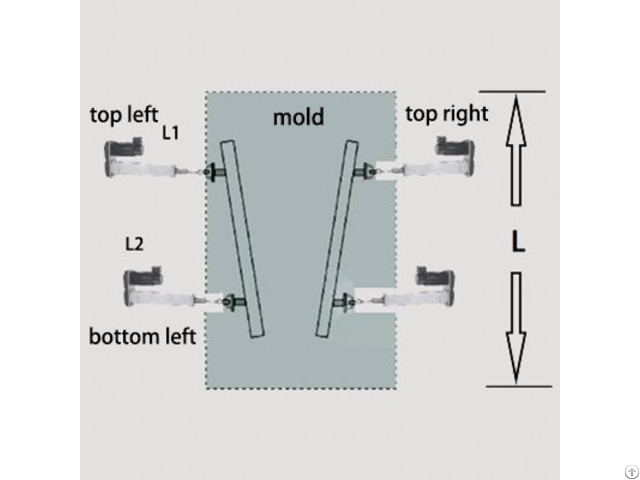

The online mold width adjustment system enables the two narrow sides of the continuous casting slab mold to move inward or outward in small steps until the predetermined width is reached.

During the production process, the adjustment of the mold’s width can be completed without stopping the machine.

Generally, the online width adjustment of the mold needs to be connected with the online taper measurement of the mold.

Only with adjustment and detection can the online adjustment range of the mold be accurately controlled.

The components of the system Workstation: host system, system width adjustment control, taper detection.

On-site operation box: real-time display of the current control status, manual operation to adjust parameters.

Digital Electric Cylinder: Precise digital control of electro-hydraulic drive cylinder, which can achieve high-precision quantitative control.

On-line measurement of taper: Install it on the narrow-face copper plate of the mold, and monitor the taper of the narrow-face copper plate in real time.

Cooperate with the detection feedback control of the width adjustment system, so as to achieve high-precision adjustment.

The technical parameters Adjustable range: 0-1250mm (unilateral) Control accuracy: 0.02mm/0.05mm/0.1mm Step resolution: 0.01mm/0.02mm Running speed: 0-10mm/s Power: 3.5KWl 16-bit encoder: 65536 pulses Weight: 25Kg Shell: high-strength aluminum alloy The functions of the system Realize online width adjustment function Realize the online real-time monitoring function of mold taper Continuous casting production adjustment and non-stop production One-key operation in the main control room, automatic completion High adjustment accuracy and fast speed The interlock control of the continuous casting steelmaking system can realize automatic steel pouring

Company Contact:

- Posted By: Wuhan CenterRise M&C Engineering CO., Ltd.

- Phone: 13995588597

- Address: Building 4, Hengxin Industrial Park, No. 8 Xinhua Avenue, Huangpi District, Wuhan , Hubei , China

- Email:

Published date: September 14, 2022

- Business Description: Wuhan CenterRise M&C Engineering Co., Ltd. is a high-tech enterprise specializing in automation products and engineering.

Our business scope includes the research and development, production and sales of automation systems, devices and various instruments.

We are a comprehensive automation company that designs, implements control systems and provides comprehensive automation systems and process control solutions.

Our company has a high-quality design and R&D team and a professional machining factory, with mature high-tech products and strong technical development and engineering strength, accumulated rich experience in the integration of industrial control systems and information systems.

Our company also cooperates closely with domestic and foreign universities and research institutes.

After years of steady and healthy development, in the fields of industrial automation, building intelligence, and network information, a high-tech enterprise development model has been formed which integrates development and design, system integration, engineering implementation, and complete equipment .

Our company focuses on the research and development of metallurgical measurement and control and automation products, and is committed to the research on key measurement and control of iron and steel metallurgical process automation.

The company's metallurgical measurement and control products cover the entire process of cokemaking, sintering, ironmaking, steelmaking, continuous casting, and steel rolling, and are widely used in major steel mills in China.

In the field of dedicated control, the company develops a series of measurement and control products for related processes, which can independently realize dedicated measurement and control, and can be seamlessly connected with basic automation systems and process automation systems.

It can provide users with comprehensive solutions for system measurement and control and automation.

Related listings

-

Mould Oscillation And Deflection Detection InstrumentIndustrial machine tools - Wuhan CenterRise M&C Engineering CO., Ltd. - China - September 13, 2022 - 5000.00 Dollar US$

Mould Oscillation And Deflection Detection InstrumentIndustrial machine tools - Wuhan CenterRise M&C Engineering CO., Ltd. - China - September 13, 2022 - 5000.00 Dollar US$Mould Oscillation and Deflection Detection Instrument Overview The mold is a device that shapes the cast product in continuous steel casting, and it is also the core equipment and key technology of continuous casting machine. The main function of the...

-

Ldt L200 Ladle Lining Laser Thickness GaugeIndustrial machine tools - Wuhan CenterRise M&C Engineering CO., Ltd. - China - September 13, 2022 - 5000.00 Dollar US$

Ldt L200 Ladle Lining Laser Thickness GaugeIndustrial machine tools - Wuhan CenterRise M&C Engineering CO., Ltd. - China - September 13, 2022 - 5000.00 Dollar US$LDT-L200 Ladle Lining Laser Thickness Gauge Overview LDT-L200 is a new generation of ladle lining thickness gauge launched by our company. The system equipment emits a pulsed laser beam to the lining surface of the ladle, and receives the returned la...

-

Spd V010 Handheld Roll Gap CheckerIndustrial machine tools - Wuhan CenterRise M&C Engineering CO., Ltd. - China - September 13, 2022 - 5000.00 Dollar US$

Spd V010 Handheld Roll Gap CheckerIndustrial machine tools - Wuhan CenterRise M&C Engineering CO., Ltd. - China - September 13, 2022 - 5000.00 Dollar US$SPD-V010 Handheld Roll Gap Checker Overview The handheld roll gap checker is specially used to measure the length between spherical surface, arc surface and plane (or spherical surface). It is specially suitable for the opening adjustment of the roll...

Safe Trade Tips

- Ask for business references and check them

- Use a payment method that offers better protection for all such as Letters of credit and verified professional escrow services. Avoid payments in advance such as money transfers

- Verify their business via their local Chamber of Commerce

- Search the internet using their website address, their business name, their phone and fax numbers, and their email addresses to see if you can find any feedback about them.

- Get to know more about scams and fraud to avoid: Internet Crime Complaint Center - Consumer Financial Protection Bureau

- This site is never involved in any transaction, and does not handle payments, shipping, guarantee transactions, provide escrow services, or offer "buyer protection" or "seller certification"