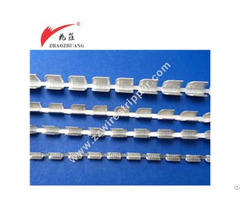

Automatic Double Ends Tin Dipping Machine Once Output Eight Wires - China

price: contact company for price

Product characteristics:

1 - Exquisite, compact design, excellent conception, small area;

2 - The Chinese operation menu of computer touch screen is easy to learn and use.

3 - Rapid replacement process and materials;

4 - Imported Sanyo motor drive with high precision and rapidity;

5 - Easy maintenance;

6 - High cost performance.

Quality and Service:

Machine maintenance for one year, the company provides training, installation, commissioning, maintenance, maintenance, life-long after-sales service.

Product Specification:

Power Supply: AC 220V/50/60HZ Single-phase

Function: Wire cutting, single-end peeling, double-end peeling, single-end tin, double-end tin parallel wire, peeling tin plating

Productivity: The production capacity of 5000 units per hour (less than 10mm in length) varies according to the type and size of the wires.

Machinable Wire Range: (AWG#18—AWG#32)

Cut length: (6mm-8000mm)

Stripping Length: Stripping Length

Air pressure: 6KGF (clean and dry air is required)

Body size: 600W×900L×1100H(mm )

Body weight: About 300kg

Product characteristics:

1 - Factory direct sales, good quality, real price, bring you real benefits.

2 - Construct a dignified atmosphere, high-precision parts imported from the original, stable performance.

3 - Simple operation, wire length, cutting speed and tin dipping time are all operated by touch screen.

4 - The output value of production capacity reaches 25, 000 finished products per hour.

5 - Line length is controlled by original Japanese Sanyo motor with high precision.

6 - Lead-free tin furnace, meeting high environmental standards; automatic scraping device to make the cut wire bright Wuxi slag residue; can set scraping time, so that tin loss to the lowest; 90 degree angle tin, tin mouth even in place.

7 - Automatic welding aid device

8 - To order this product, we deliver it to your door and train our staff in the whole process.

The product is sold with a one-year warranty, lifelong maintenance and after-sale all day.

9 - Owning this equipment (difficult recruitment, high salary, difficult management) is no longer a problem for you.

Without all complicated procedures, an ordinary employee can easily manage several machines.

Company Contact:

- Phone: +86-0577-88935088

- Address: 2nd Floor, Building 1, No. 128, Juguangyuan Middle Road, Ouhai District, Wenzhou, Zhejiang, China, wenzhou , zhejiang , China

- Email:

Published date: September 22, 2019

- Business Description: Wenzhou Zhaozhuang Automation Equipment Co., Ltd. specializes in the production of enameled wire stripping-free piercing terminal, motor copper-clad aluminum, copper, aluminum enameled wire end and power lead-out welding new scheme, using the paint-free piercing terminal crimping process, Five processes, such as lacquering, winding, dip flux, immersion tin, trimming head, etc., can be energized with one pressure, saving money and labor, making the environmental protection of production process and production products reach the international advanced level and improving Production efficiency.

The workers' stripping machine, tin furnace and tin dust equipment are all in the province.

As the country becomes more and more strict with environmental protection, this process directly subverts the soldering process.

The products are used in motors and motors, air conditioner motors, exhaust motors, capacitor motors.

, range hood motor, DC brushless motor, small AC and DC motor, water pump, air compressor, washing machine, generator, transformer, power tools, etc.

Our company has developed the latest enamelled wire stripping-free piercing terminal, which does not require stripping and soldering, so that the process of enameled wire and aluminum enameled wire is more environmentally friendly and simple.

Reduce production, reduce production processes and labor, and greatly improve production efficiency.

This product can be used to change the welding or riveting process of the original stripping of copper and aluminum enameled wires.

It can realize one-time crimping and conduction, and the electrical performance is stable.

Compared with the original process, it saves time and labor.

Environmentally friendly, non-polluting, and more stable performance, fully meet the ROHS directive requirements.

Currently, the product is widely used by many manufacturers of electrical and mechanical equipment and related enameled wire connection products.

The piercing terminal is adapted to connect the double-stranded or multi-strand enameled wire in parallel with the power lead-out wire, and the production and operation of the terminal block and the copper and aluminum paint stripping terminal (anti-oxidation, good electrical performance).

In addition, our company specializes in producing automatic scraping machine, computer stripping machine, peeling and ending machine, automatic peeling and ending machine, cable tie tightening machine, servo terminal machine, fully automatic eight-head dip tinning machine, off Wire harness processing equipment such as paint machine and various terminal connectors, welcome new and old customers to inquire.

Related listings

-

No Strip Twist Tin Splice Crimp Cable Connector 62306 2 Magnet Wire TerminalIndustrial process machinery - Wenzhou Zhaozhuang Automation Equipment Co., Ltd. - China - September 22, 2019 - contact company for price

No Strip Twist Tin Splice Crimp Cable Connector 62306 2 Magnet Wire TerminalIndustrial process machinery - Wenzhou Zhaozhuang Automation Equipment Co., Ltd. - China - September 22, 2019 - contact company for priceFeature: 1. Enameled wires does not need paint stripping, direct electrical connection after pressing. 2. Good bonding effect, eliminate cold welding point, hot melting point, virtual welding. 3. High efficiency, Antioxidant. 4. Cost saving. 5. Envir...

-

Semi Automatic Wire Labeling MachineIndustrial process machinery - Wenzhou Zhaozhuang Automation Equipment Co., Ltd. - China - September 22, 2019 - contact company for price

Semi Automatic Wire Labeling MachineIndustrial process machinery - Wenzhou Zhaozhuang Automation Equipment Co., Ltd. - China - September 22, 2019 - contact company for priceUsage Applicable Label: Self-adhesive Label Applicable products: products that need to be folded and labeled on wires, tubes, rods or other special-shaped interfaces; Applied industries: widely used in food, toys, daily chemicals, electronics, medici...

-

Xc 65 35l Choking Coil Inductance Cutting Shaping Straighten Forming MachineIndustrial process machinery - Wenzhou Zhaozhuang Automation Equipment Co., Ltd. - China - September 22, 2019 - contact company for price

Xc 65 35l Choking Coil Inductance Cutting Shaping Straighten Forming MachineIndustrial process machinery - Wenzhou Zhaozhuang Automation Equipment Co., Ltd. - China - September 22, 2019 - contact company for priceType of choking coil Inductance coil: external diameter 6-30 mm Maximum foot distance: 20mm Maximum row spacing: 25mm Line diameter range: 0.3MM-1.OMM Average output value: 800-3000PCS/h Working Principle: Clamping, pulling and breaking all the best ...

Safe Trade Tips

- Ask for business references and check them

- Use a payment method that offers better protection for all such as Letters of credit and verified professional escrow services. Avoid payments in advance such as money transfers

- Verify their business via their local Chamber of Commerce

- Search the internet using their website address, their business name, their phone and fax numbers, and their email addresses to see if you can find any feedback about them.

- Get to know more about scams and fraud to avoid: Internet Crime Complaint Center - Consumer Financial Protection Bureau

- This site is never involved in any transaction, and does not handle payments, shipping, guarantee transactions, provide escrow services, or offer "buyer protection" or "seller certification"