High Quality Gypsum Board Production Line Equipment - China

price: 5000000.00 Dollar US$

Gypsum board production line based configuration table

Annual production(㎡) Plant area(㎡) Drying method Total installed capacity Productin linespeed

(m/min) Requird workers Electrical configuration

1.5 million 60m×26m Thermal oil 116kw 3.0 8 Siemens

2million 70m×26m Thermal oil 127kw 4.2 10 Siemens

3million 84m×30m Thermal oil 166kw 6.25 11 Siemens

4million 110m×30m Thermaloil/Hot stove 210kw 8 11 Siemens

5million 112m×30m Thermaloil/Hot stove 234kw 10.5 11 Siemens

6million 122m×30m Thermaloil/Hot stove 240kw 12.5 11 Siemens

8million 136m×30m Thermaloil/Hot stove 349kw 16.5 11 Siemens

10million 150m×30m Thermaloil/Hot stove 467kw 20 12 Siemens

12million 172m×30m Thermaloil/Hot stove 488kw 24 13 Siemens

15million 204m×36m Thermaloil/Hot stove 578kw 31 15 Siemens

20million 240m×40m Thermaloil/Hot stove 778kw 40 15 Siemens

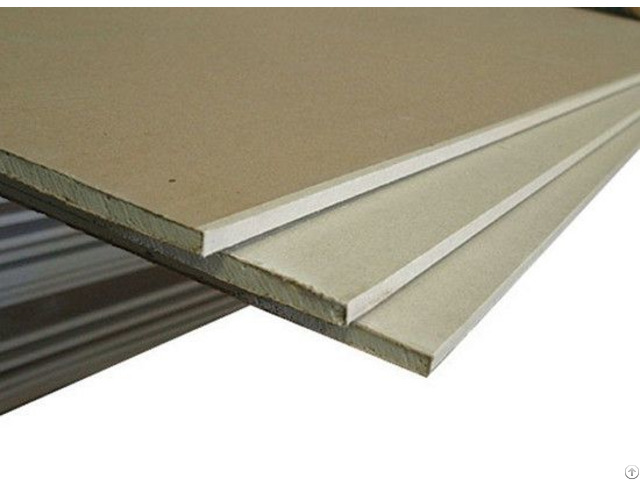

Product specifications: length 2400—3000mm width 1200—1220mm thickness 8—15mm Gypsum board production line is the current production of new special equipment for decorative materials, the main work processes include:

1 - The plaster and water and various additives, respectively, by automatic metering, automatic delivery system into the mixer, mixing into a gypsum slurry, and evenly sprinkled in the continuous forward movement of the face paper;

2 - In the continuous forward while vibrating, the slurry gradually spread evenly, then into the extrusion molding machine and the upper and lower face paper complex, by the extrusion molding pulp is completely covered by the upper and lower skin paper, and extruded into Continuous slurry gypsum board;

3 - The board in the molding line during the operation after shaping, natural solidification, automatic cutting, etc.

have been gradually formed wet solid gypsum board, wet board by the program-controlled system, through the roller, belt conveyor and flap quickly into the drying room;

4 - The board in the drying room under the strict control of each temperature zone, and into the hot air at different temperatures, wet plate evaporation, starch reaction and the board bonded to the protective paper, dried gypsum board from the drying room stand out;

5 - And then flap again and pieces (front-facing), the length of the saw will cut the board into a certain size of the finished board;

6 - The final delivery to automatic head and automatic stacking, palletizing completed by the forklift truck to the finished product warehouse.

Annual output: 1.5 million square meters / year -3000 square meters / year

1 - Reasonable design, perfect matching, reliable operation;

2 - My company has: less investment, fast construction, low operating costs, cost-effective advantages;

3 - Set the production line design, manufacture, installation, commissioning, production in one, created a number of elite teams;

4 - Customer success, customer development for business purposes, long-term cooperation for a better future for the idea.

Company Contact:

- Posted By: Shijiazhuang Wuxing Mec hanical Co., Ltd.

- Phone: +8615832478108

- Address: Jinzhou Industrial Road, Shijiazhuang , Hebei , China

- Email:

Published date: June 6, 2019

- Business Description: Shijiazhuang Wuxing Mechanical Co., Ltd established in 2005, is a professional manufacturer engaged in the research, development, production, sale and service of gypsum board production line, Gypsum powder production line, calcium silicate board production machine and Light Mineral Wool Board production machine.

Related listings

-

Gypsum Board Production Line Equipment ManufacturerIndustrial process machinery - Shijiazhuang Wuxing Mechanical Co., Ltd. - China - June 6, 2019 - 5000000.00 Dollar US$

Gypsum Board Production Line Equipment ManufacturerIndustrial process machinery - Shijiazhuang Wuxing Mechanical Co., Ltd. - China - June 6, 2019 - 5000000.00 Dollar US$Gypsum board production line is the current production of new special equipment for decorative materials, the main work processes include: 1. The plaster and water and various additives, respectively, by automatic metering, automatic delivery system ...

-

Advanced Gypsum Board Production Line EquipmentIndustrial process machinery - Shijiazhuang Wuxing Mechanical Co., Ltd. - China - June 6, 2019 - 5000000.00 Dollar US$

Advanced Gypsum Board Production Line EquipmentIndustrial process machinery - Shijiazhuang Wuxing Mechanical Co., Ltd. - China - June 6, 2019 - 5000000.00 Dollar US$Gypsum board production line is the current production of new special equipment for decorative materials, the main work processes include: 1. The plaster and water and various additives, respectively, by automatic metering, automatic delivery system ...

-

Professional Gypsum Board Production Line EquipmentIndustrial process machinery - Shijiazhuang Wuxing Mechanical Co., Ltd. - China - June 6, 2019 - 5000000.00 Dollar US$

Professional Gypsum Board Production Line EquipmentIndustrial process machinery - Shijiazhuang Wuxing Mechanical Co., Ltd. - China - June 6, 2019 - 5000000.00 Dollar US$Introduction of the Equipment Gypsum board production line specifications models, complete sets of prices, is based on user requirements of product quality, product output, raw material structure and other factors designed to determine. Annual output...

Safe Trade Tips

- Ask for business references and check them

- Use a payment method that offers better protection for all such as Letters of credit and verified professional escrow services. Avoid payments in advance such as money transfers

- Verify their business via their local Chamber of Commerce

- Search the internet using their website address, their business name, their phone and fax numbers, and their email addresses to see if you can find any feedback about them.

- Get to know more about scams and fraud to avoid: Internet Crime Complaint Center - Consumer Financial Protection Bureau

- This site is never involved in any transaction, and does not handle payments, shipping, guarantee transactions, provide escrow services, or offer "buyer protection" or "seller certification"