Pet Bottles Crushing Washing Line For Plastic Recycling Machine - China

price: 1.00 Dollar US$

1, To separate PET bottles to flakes from PE/ PP label, cap, oil, garbage, protect the environment, avoid white pollution.

This recycling line is composed of separator, crusher, cold & hot washing system, dewatering, drying, packing system, etc.

2, This Plastic flakes crushing, recycling and washing production line can easily wash and recycle waste PET PP PE bottle flakes.

Waste and dirty Plastic PET PP PE bottle flakes can be treated step by step by this facility.

It is special for washing Plastic flakes.

3, We can help to attach equipment at the end of the washing line so that the completely dry flakes can be collected and packed directly after being washed.

4, The whole production line can be designed on the basis of how dirty the flakes are, and make sure of the quality of the final products.

5, Coordinating the production line with follow programmed work (granulating system), and it will make waste and dirty PET PP PE bottles to be the granule material and in order to producing new Plastic bottles.

6, After the this PET bottle flakes crushing, recycling and washing production line, our company also offer the following production lines of Plastic bottle granulating to make the waste and dirty Plastic bottle be the new finished products.

The whole production equipment is researched, design and manufactured by our company, integration of advanced technology, it has features as high efficiency, working stable, large capacity etc.

Waste Plastic Pet Bottle Crushing Washing Drying Recycling Line / Machine / Plant is widely used to treat waste plastic, such as PET / PVC / HDPE bottle, water bottles, cola bottle and PET plastic scrap broken into flakes.

Pet bottle recycling line is a crushing, washing, drying line.

PET flakes are mainly used for the fiber production PET strap, PET sheet, and other related PET products.

With advanced international industry concepts and technologies to meet waste plastic recycling at home or abroad.

this line can be displayed "L" or "U" shape.

We can also customized the line according the customer's request; 1 - Realize one production line can process different kinds of raw material; 2 - Good quality on our machine(SUS-304 stainless steel, more than 4mm thickness) 3 - High quality on final product, low humidity content (Less than 1%) and impurities ( Less than 50PPM).

4 - If you want to join the environmental industry, pls feel free to contact with me, tks.

Product Application FANGTAI PET bottles crushing washing line for plastic recycling machine / recycle machine Brief description: FANGTAI PET bottles crushing washing line for plastic recycling machine / recycle machine Plastic recycling line is designed for waste film and bags washing, with full system configuration including: crushing, flotation, hot washing, drying, etc, which can be used to make granules directly or some other use.

Features of plastic recycling line: FANGTAI PET bottles crushing washing line for plastic recycling machine / recycle machine 1 - Humidity content: <2-5% 2 - Capacity: 300-3000kg/h 3 - Plastic recycling line is used to crush, wash, dewater and dry plastic film.

4 - Simple structure, easy operation, high capacity, low energy consumption, safety, reliability, etc.

5 - Parts which contact material use SUS304, thickness usually 3mm, ensure long service lift time Applicable material: FANGTAI PET bottles crushing washing line for plastic recycling machine / recycle machine PE, PP, BOPP, HDPE, LDPE, LLDPE, ABS, EPE, EPS, XPS, Stretch film, plastic bags, etc.

Process flow of flakes Washing recycling Machine line: FANGTAI PET bottles crushing washing line for plastic recycling machine / recycle machine Belt convey→Label remover →manual pick table Belt convey → Crusher →washing tank1 → washing tank 2→friction machine → hot washing 1→ hot washing2 → High speed friction washing machine → washing tank →Friction washing → Dewatering machine → Storage hopper → Finished product packing Description of Application Coordinating the production line with follow programmed work (granulating system), and it will make waste and dirty PET bottles to be the dry and clean flakes.

Then widely used in the construction industry, clothing industry, plastic industry and so on.

Company Contact:

- Phone: 86-312-7638778

- Address: Baimiao Industrial District,Shunping County ,Baoding city,Hebei province,China, Baoding , Hebei , China

- Email:

Published date: March 29, 2022

- Business Description: Hebei Fangtai plastic machinery manufacture Co., Ltd. was founded in 2004, which is professional for waste plastic processing machinery.

We are located in Baoding City, Hebei Province, and enjoying convenient transportation access.

We are focused on researching and developing new products to meet markets and customers' satisfaction.

With abundant strength, we have lots of professional technicists and skilled workers.

Dedicated to strict quality control and thoughtful customer service, our experienced staff members are always available to discuss your requirements and ensure full customer satisfaction.

We strictly carry on Product quality standard to produce and test.

We are fully committed to producing technologically advanced kinds of PET bottles / pp pe / Garbage crushing washing drying recycling line; multifunctional plastic recycling line; All kinds of crushers, washers, granulators, dryers, label removers, baler, bale breaker and other plastic recycling machines.

Our products sell well both in domestic and international markets, before we exported to Czech Republic, America, Russia, Japan, Montenegro, Lebanon,Chile, Mexico, Algeria, Ethiopia, Nigeria, egypt, Turkmenistan, Uzbekistan, Tunisia, Bangladesh, India, SriLanka, Malaysia, Indonesia, Yemen, Thailand, cambodia, Pakistan, Jordan, Libya and other countries; We will continuously introduce international advanced technology to produce better product lines.

With sound business credit, guaranteed after-sales service, and modern manufacturing facilities, we have earned an reputation among our customers across the globe.

Fully automated production facilities utilize the best in material, technology and humanresources, all of which are geared to provide complete customer satisfaction.

We welcome you to contact us and look forward to working with you! Fangtai plastic machinery keeps high pace with the times, pioneers and innovates, We sincerely welcome traders both from home and abroad to discuss business with us! We are looking forward to join hands with you to achieve common progress and create a brilliant future!

Related listings

-

Pet Bottle Pp Pe Recycling MachineryIndustrial process machinery - Hebei fangtai plastic machinery manufacture co,.ltd - China - March 29, 2022 - 1.00 Dollar US$

Pet Bottle Pp Pe Recycling MachineryIndustrial process machinery - Hebei fangtai plastic machinery manufacture co,.ltd - China - March 29, 2022 - 1.00 Dollar US$High grade capacity pet bottles washing recycling line The whole production equipment is researched, design and manufactured by our company, integration of advanced technology, it has features as high efficiency, working stable, large capacity etc. W...

-

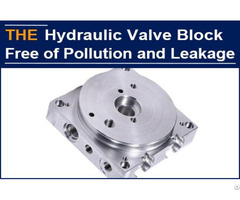

Aak Succeeded To Produce Leak Free Hydraulic Valve Blocks With Swiss TechnologyIndustrial process machinery - AAK Industry CO., LTD - China - March 24, 2022 - 100.00 Dollar US$

Aak Succeeded To Produce Leak Free Hydraulic Valve Blocks With Swiss TechnologyIndustrial process machinery - AAK Industry CO., LTD - China - March 24, 2022 - 100.00 Dollar US$Smith is the head purchasing of a hydraulic company from California. His purchasing of hydraulic valves in recent years has been smooth. In the last hydraulic valve block order, the parameters were normal when the hydraulic valve block approval sampl...

-

Automatic Hydraulic Decoiler Machine For Metal Coil UncoilingIndustrial process machinery - Fanty Machinery - China - March 23, 2022 - contact company for price

Automatic Hydraulic Decoiler Machine For Metal Coil UncoilingIndustrial process machinery - Fanty Machinery - China - March 23, 2022 - contact company for priceDecoiler Functions 1) Storage of coils 2) Unwinding the metal plate from coils 3) Rewinding the uncut metal plate from coil to coil Decoiler Specification 2 Ton Decoiler Machine Model MT-500 Coil Width Max. 500mm Material Thickness 0.1-2.2mm Coil Wei...

Safe Trade Tips

- Ask for business references and check them

- Use a payment method that offers better protection for all such as Letters of credit and verified professional escrow services. Avoid payments in advance such as money transfers

- Verify their business via their local Chamber of Commerce

- Search the internet using their website address, their business name, their phone and fax numbers, and their email addresses to see if you can find any feedback about them.

- Get to know more about scams and fraud to avoid: Internet Crime Complaint Center - Consumer Financial Protection Bureau

- This site is never involved in any transaction, and does not handle payments, shipping, guarantee transactions, provide escrow services, or offer "buyer protection" or "seller certification"