Shell Molding Machine Kkb 550 Vertical - Taiwan

price: contact company for price

Core Shooting Machine and Shell Molding Machine KKB-550 Vertical 1 - Core Box Size (L x H x W): 550 x 400 x 300 mm

2 - Max.

Core Size (L x H x W): 470 x 380 x 250 mm

3 - Operation Mode: Manual/Single Cycle/Auto Cycle

4 - Production Speed: 40 ~ 70 seconds/cycle, depends on size and shape of products

5 - Heating Type: LPG or Electrical

6 - Max.

Blowing Capacity: 15-30 kgs

7 - Sand Storage Capacity: 200-300 kgs

8 - Operation Pressure: 5-6 kgs/cm²

9 - Sand Blowing Pressure: 1-4 kgs/cm²

10 - Weight: 2500 kgs

11 - Dimension: 2010 x 3340 x 2850 mm

Company Contact:

- Posted By: Kao Kuen Industrial Co., LTD

- Phone: 886-4-22782219

- Address: No. 39, Alley 42, Lane 1463, Kwang Hsin Rd., Taiping Dist., , Taichung City, Taiwan

- Email:

- Website: http://www.kaokuen.com.tw

Published date: December 2, 2019

- Business Description: Kao Kuen Industrial Co., a professional manufacturer of core shooting machine and shell molding machines, has accumulated a solid knowledge and experience in making most effective, economic and durable machines for more than 30 years.

Related listings

-

Core Shooting Machine Kka 550 VerticalMixers and their parts and accessories - Kao Kuen Industrial Co., LTD - Taiwan - December 2, 2019 - contact company for price

Core Shooting Machine Kka 550 VerticalMixers and their parts and accessories - Kao Kuen Industrial Co., LTD - Taiwan - December 2, 2019 - contact company for priceCore Shooting Machine and Shell Molding Machine KKA-550 Vertical 1. Core Box Size (LxHxW) mm: 550x400x300 2. Max. Core Size (LxHxW) mm: 470x380x250 3. Operation Mode: Manual/Single Cycle/Auto Cycle 4. Production Speed: 40 ~ 70 seconds/cycle, depends ...

-

Silicon Molybdenum Rod For Heating Element In Roller Kiln Tunnel Mosi2 HeaterMixers and their parts and accessories - Zhengzhou Mingxin electric heating materials Co., Ltd - China - November 26, 2019 - 18.88 Dollar US$

Silicon Molybdenum Rod For Heating Element In Roller Kiln Tunnel Mosi2 HeaterMixers and their parts and accessories - Zhengzhou Mingxin electric heating materials Co., Ltd - China - November 26, 2019 - 18.88 Dollar US$Products Description Whats the Molybdenum disilicide(MoSi2) heating element? Molybdenum disilicide(MoSi2) heating element is one resistance heating component made from MoSi2 or as the basic material. When its heated to high temperature under the oxid...

-

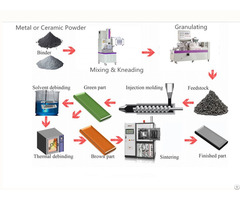

Metal Powder Mixer For MimMixers and their parts and accessories - Dongguan Cfine Machinery technology Co., Ltd - China - August 19, 2019 - check with company for price

Metal Powder Mixer For MimMixers and their parts and accessories - Dongguan Cfine Machinery technology Co., Ltd - China - August 19, 2019 - check with company for priceApplications: A metal powder kneader is specially used for metal powder injection molding. Many materials such as Iron-based alloy steel, stainless steel, nickel-based alloy, tungsten alloy, hard alloy, titanium alloy, magnetic material, Kovar alloy,...

Safe Trade Tips

- Ask for business references and check them

- Use a payment method that offers better protection for all such as Letters of credit and verified professional escrow services. Avoid payments in advance such as money transfers

- Verify their business via their local Chamber of Commerce

- Search the internet using their website address, their business name, their phone and fax numbers, and their email addresses to see if you can find any feedback about them.

- Get to know more about scams and fraud to avoid: Internet Crime Complaint Center - Consumer Financial Protection Bureau

- This site is never involved in any transaction, and does not handle payments, shipping, guarantee transactions, provide escrow services, or offer "buyer protection" or "seller certification"