Palm Kernel Oil Refining Process - China

price: 150000.00 Dollar US$

Over the past 30 years, the worldwide area planted to oil palm has increased by more than 150 percent.

The palm oil contains rich vitamin A in the original (500-700 parts per million (PPM) and vitamin E (500-800 parts per million (PPM).

Now in the market more and more customers have received the palm oil and it develops in a rapid speed.

So Palm Oil Refining is one question most oil processing manufactures to resolve.

Palm kernels are pre-treated by magnetic separators that removed metallic debris that might destroy your palm kernel oil press equipment.

Then the kernels are sieved to remove sands, stones and other Impurities before cracking with inbuilt swinging hammers.

The nuts are separated from the shells after cracking and prepared by heating before extracted with expeller press.

The nuts are screwed through a metallic path (with pores) that decreases in diameter to the exit so that the oil is forced out of the side while the cake is collected at the tip of the screw.

Finally, palm kernel oil (PKO) obtained via mechanical means are usually filled with impurities that must be removed by further processing.

Oil refining is based on the different usage and requirements, utilizing the physical methods and chemical processes to get rid of the harmful impurities and needless substance in the crude oil, getting standard oil.

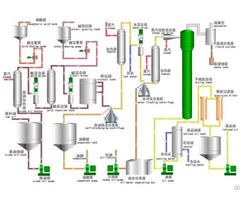

Equipment of Palm Oil Refining Process:

Degumming section:

Degumming is the first and basic step in the crude oil refinery plant, degumming process aims to removing the gum impurities in the crude oil to make it suitable for further refinery process, hydration degumming and special acid degumming are the two main methods.

Deacidification section:

The deacidification system uses versatile neutralization technology, which is developed to deal with oilseeds of different species and qualities in the oil refining plant, it can realize both degumming and neutralization processes by adding alkali, water and acid, then with FFA, crude phospholipids and moisture all removed, the oil and by products (soap foot, phospholipids) are separated.

Bleaching section:

The oil bleaching is also named decolorization in oil refinery processes.

This process’s main purpose is to remove the product of oxidation, pigments, phospholipids, soap materials from the oil.

In the oil refinery plant, this process can improve the oil color as well as supplies high quality oil for the deodorization process.

Deodorization section:

Deodorization section is very crucial in edible oil refinery plant in first grade oil production as it improves the flavor of the oil; the quality of deodorization equipment has great effect to the oil quality.

Company Contact:

- Posted By: Henan Doing Mechanical Equipment Co., Ltd

- Phone: +86 13526627860

- Address: No.133 Yaozhai Road, Jinshui District, Zhengzhou City, Henan Province, China , zhengzhou , Asia , China

- Email:

Published date: September 9, 2016

- Business Description: Henan Doing Machinery Equipment Co., Ltd. has been dedicated to the research and development of large, medium-sized and small -sized palm oil processing machine and a variety of edible oil extraction machine for years.

We are professional manufacturing enterprise which gather development, design, production, sales, installation and after-sales service in one.

Our palm oil processing machine and palm kernel oil processing machine have gained many achievements and awards.

And we have installed palm oil processing machine in more than 30 countries over the world.

Such as Malaysia, Indonesia, Thailand, Nigeria, Liberia, Kenya, Ghana, Cote d'Ivoire, Congo, Zambia and so on.

http: //www.

palmoilextractionmachine.

com

http: //www.

edibleoilextractionmachine.

com

Related listings

-

Corn Germ Oil Extraction PlantRaw materials processing machinery - Henan Doing Mechanical Equipment Co., Ltd - China - September 9, 2016 - 150000.00 Dollar US$

Corn Germ Oil Extraction PlantRaw materials processing machinery - Henan Doing Mechanical Equipment Co., Ltd - China - September 9, 2016 - 150000.00 Dollar US$The corn germ oil extraction plant designed by Wintone Machinery adopts advanced fine corn processing flow line design to produce grade corn flour, gits, germ and fine feeds with dry milling method, ensuring quality product up to national standard.Th...

-

Small Scale Cooking Oil Refining PlantRaw materials processing machinery - Henan Doing Mechanical Equipment Co., Ltd - China - September 9, 2016 - 150000.00 Dollar US$

Small Scale Cooking Oil Refining PlantRaw materials processing machinery - Henan Doing Mechanical Equipment Co., Ltd - China - September 9, 2016 - 150000.00 Dollar US$After oil pressing process or oil extraction process, we get crude oil. But the crude oil can’t flow to supermarket. The crude oil must need processing with cooking oil refining plant, especially soybean, cottonseed, rapeseed, palm kernel, etc. Then ...

-

Cooking Vegetable Edible Oil Refinery MachineRaw materials processing machinery - Henan Doing Mechanical Equipment Co., Ltd - China - September 9, 2016 - 150000.00 Dollar US$

Cooking Vegetable Edible Oil Refinery MachineRaw materials processing machinery - Henan Doing Mechanical Equipment Co., Ltd - China - September 9, 2016 - 150000.00 Dollar US$Edible Oil Refinery : Cooking Oil Refinery : Vegetable Oil Refinery Edible Oil Refinery and Edible Oil Refining have been the areas of excellence for cooking oil refining technology. We are the basic designers, manufacturers and exporters of complete...

Safe Trade Tips

- Ask for business references and check them

- Use a payment method that offers better protection for all such as Letters of credit and verified professional escrow services. Avoid payments in advance such as money transfers

- Verify their business via their local Chamber of Commerce

- Search the internet using their website address, their business name, their phone and fax numbers, and their email addresses to see if you can find any feedback about them.

- Get to know more about scams and fraud to avoid: Internet Crime Complaint Center - Consumer Financial Protection Bureau

- This site is never involved in any transaction, and does not handle payments, shipping, guarantee transactions, provide escrow services, or offer "buyer protection" or "seller certification"