Axle Head Co2 Automatic Welding Machine I Design Mission - China

price: check with company for price

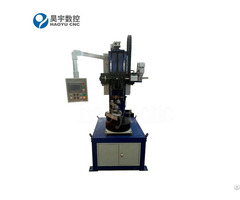

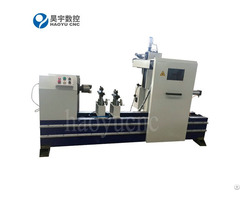

Axle Head CO2 Automatic Welding Machine

I.

Design mission Complete the automatic welding of two circular seams in the joint between axle head and axle housing.

To make sure that welding specification is even and uniform.

With uniform surface and good appearance.

Easy and reliable to use, welding quality meets welding requirement, quick and convenient to load and clamp.

II.

Basic Conception

Welding torch is fixed, while the workpiece is rotating.

Welding position is horizontal.

The two ends of axle are pressed pneumatically and rotate together.

Using double water-cooling torches and two power sources to reduce the welding deformation.

The machine has high voltage and slow wire feeding performance, which guarantees reliable arc igniting.

Machine also has low welding voltage and low current for filling crater.

The welding torch must have oscillating and synchronous lifting functions to realize the automatic lifting and oscillating of the welding torch during the welding process to complete the multilayer welding and fill up the welding pass.

The welding current, voltage and welding speed of each layer in each welding parameter, the welding torch oscillating frequency, oscillating scope, oscillating time, welding torch automatic lifting time, lifting distance and lifting frequency can be preset and recalled in steps.

100 sets of welding parameters can be pre-stored.

Welding torch, rotation axis box and tailstock can be adjusted longitudinally, to meet different types welding.

Using PLC to control the whole machine operating, AC frequency speed regulator, to improve the reliability of equipment.

Adopts axis central hole position and pneumatic pressed mode.

Using the man-machine interface to modify parameter.

III.

Electric Control System

1 - Using OMRON PLC as control core, control the implementation of the welding program.

Stable system, simple structure, easy maintenance.

2 - The rotation of workpiece adopts Japan Panasonic AC frequency regulator.

The rotation speed is adjusted by controlling driver to adjust motor speed, stepless adjustment, it can be displayed by CM/MIN, low rate and suit for long time use.

3 - Taiwan Wei Lun MT-6070I 7- inch touch screen as the input and output interface.

Welding length, arc igniting, arc ending time, welding current, welding voltage, welding speed, oscillating frequency, oscillating scope, oscillating time, torch lifting time, torch lifting distance, torch lifting times can be all input through the interface.

4 - Rotary closed-loop encoder will detect welding length.

Position detection: torch position is detected by imported non-contact switch 5 - The welding starting point is automatically detected and returned to the original position automatically after welding.

6 - Integrated control panel box.

Control button, touch screen, welding specification are in one panel, easy to be used and operated.

Company Contact:

- Posted By: Jinan Haoyu CNC Machinery Co., Ltd.

- Phone: 18865822870

- Address: Middle MingjIa Road,Qihe Economy Development Zone, Dezhou , Shandong , China

- Email:

- Website: http://www.haoyucnc.com

Published date: July 28, 2018

- Business Description: Jinan Haoyu CNC Machinery Co., Ltd.is a welding machinery maker in Jinan China .

We have a strong design and technical team and can design and manufacture the machines as customers requirements.

Our products mainly include automatic welding machine, robot welding station, automatic pipe cutting machine, automatic material handling equipment, automatic assembling machine, which are used in the areas of automobile, construction, railway vehicle, electric power, shipbuilding, pressure container, petrochemical, house appliances and military industry, etc.

Related listings

-

Automatic Welding Machine Of High Pressure Oil PipeWelding and soldering and brazing machinery - Jinan Haoyu CNC Machinery Co., Ltd. - China - July 28, 2018 - check with company for price

Automatic Welding Machine Of High Pressure Oil PipeWelding and soldering and brazing machinery - Jinan Haoyu CNC Machinery Co., Ltd. - China - July 28, 2018 - check with company for priceAutomatic Welding Machine of High-pressure Oil Pipe Technical Requirement It is mainly used to automatically weld angle shape circular seam of various hard tube. Make sure the welding specification is uniform, good appearance. It is easy to operate, ...

-

Steel Pipe Flange Double Torch Circular Seam Welding MachineWelding and soldering and brazing machinery - Jinan Haoyu CNC Machinery Co., Ltd. - China - July 28, 2018 - check with company for price

Steel Pipe Flange Double Torch Circular Seam Welding MachineWelding and soldering and brazing machinery - Jinan Haoyu CNC Machinery Co., Ltd. - China - July 28, 2018 - check with company for priceSteel Pipe Flange Double Torch Circular Seam Welding Machine 1).Technical Requirement Mainly used for automatically welding flange circular seam of various specifications. To guarantee even and uniform welding specification, nice welding appearance. ...

-

Square Valve Seat Cnc Circular Seam Automatic Welding MachineWelding and soldering and brazing machinery - Jinan Haoyu CNC Machinery Co., Ltd. - China - July 28, 2018 - check with company for price

Square Valve Seat Cnc Circular Seam Automatic Welding MachineWelding and soldering and brazing machinery - Jinan Haoyu CNC Machinery Co., Ltd. - China - July 28, 2018 - check with company for priceSquare Valve Seat CNC Circular Seam Automatic Welding Machine 1. Design Mission Hydraulic cylinder CNC circular seam automatic welding machine should meet the automatic welding of U-shape and circular seam. Make sure that welding specification is uni...

Safe Trade Tips

- Ask for business references and check them

- Use a payment method that offers better protection for all such as Letters of credit and verified professional escrow services. Avoid payments in advance such as money transfers

- Verify their business via their local Chamber of Commerce

- Search the internet using their website address, their business name, their phone and fax numbers, and their email addresses to see if you can find any feedback about them.

- Get to know more about scams and fraud to avoid: Internet Crime Complaint Center - Consumer Financial Protection Bureau

- This site is never involved in any transaction, and does not handle payments, shipping, guarantee transactions, provide escrow services, or offer "buyer protection" or "seller certification"