China Sheet Metal Laser Cutter Machine - China

price: 15000.00 Dollar US$

The sheet metal laser cutter adopts IGOLDENCNC fiber laser source, an integral gantry-type mechanism system and an intelligent laser cutting head.

It can support large, effective processing formats and intelligent cutting with long service life and smooth cutting effect.

In addition, the aluminum sheet metal laser cutter has a complete dust-proof and anti-pollution design, which greatly improves the stability of the machine’s performance, processing efficiently and fluently.

sheet metal laser cutter How sheet metal laser cutter works

The laser beam is a column of very high intensity light, of a single wavelength, or color.

In the case of a typical CO2 laser, that wavelength is in the Infra-Red part of the light spectrum, so it is invisible to the human eye.

The beam is only about 3/4 of an inch in diameter as it travels from the laser resonator, which creates the beam, through the machine’s beam path.

It may be bounced in different directions by a number of mirrors, or “beam benders”, before it is finally focused onto the plate.

The focused laser beam goes through the bore of a nozzle right before it hits the plate.

Also flowing through that nozzle bore is a compressed gas, such as Oxygen or Nitrogen.

Focusing the laser beam can be done by a special lens, or by a curved mirror, and this takes place in the laser cutting head.

The beam has to be precisely focused so that the shape of the focus spot and the density of the energy in that spot are perfectly round and consistent, and centered in the nozzle.

By focusing the large beam down to a single pinpoint, the heat density at that spot is extreme.

Think about using a magnifying glass to focus the sun’s rays onto a leaf, and how that can start a fire.

Now think about focusing 6 KWatts of energy into a single spot, and you can imagine how hot that spot will get.

The high power density results in rapid heating, melting and partial or complete vaporizing of the material.

When cutting mild steel, the heat of the laser beam is enough to start a typical “oxy-fuel” burning process, and the laser cutting gas will be pure oxygen, just like an oxy-fuel torch.

When cutting stainless steel or aluminum, the laser beam simply melts the material, and high pressure nitrogen is used to blow the molten metal out of the kerf.

On a laser sheet metal cutting machine, the laser cutting head is moved over the metal plate in the shape of the desired part, thus cutting the part out of the plate.

A capacitive height control system maintains a very accurate distance between the end of the nozzle and the plate that is being cut.

This distance is important, because it determines where the focal point is relative to the surface of the plate.

Cut quality can be affected by raising or lowering the focal point from just above the surface of the plate, at the surface, or just below the surface.

There are many, many other parameters that affect cut quality as well, but when all are controlled properly, laser cutting is a stable, reliable, and very accurate cutting process.

Features of sheet metal laser cutter: Powerful ProCutter For High Power Cutting A smart cutting head guarantees high dynamic performance for thin material cutting and best quality when cutting thick materials.

It operates stably with laser power of up to 30 kW.

You benefit from stable performance both at cutting thick CS plates and curved contours.

Cast Aluminum Crossbeam The crossbeam boasts of high rigidity and light weight, promising a high dynamic response and processing efficiency.

Double Exchange Platform Auto up & down chain-type parallel pallets system keeps your production flowing without machine stop.

With an immediate switch, you benefit from the fastest speed of pallet exchanging.

Safety and Clean, 0 Pollution Fully enclosed structure, safety viewing window, dust removal system, etc., every detail promises a safe and pollution-free production environment.

Pipe Processing The fully automatic torque control electric chucks clamp large diameter pipes and provide adjustable current, stable performance as well as great clamping force.

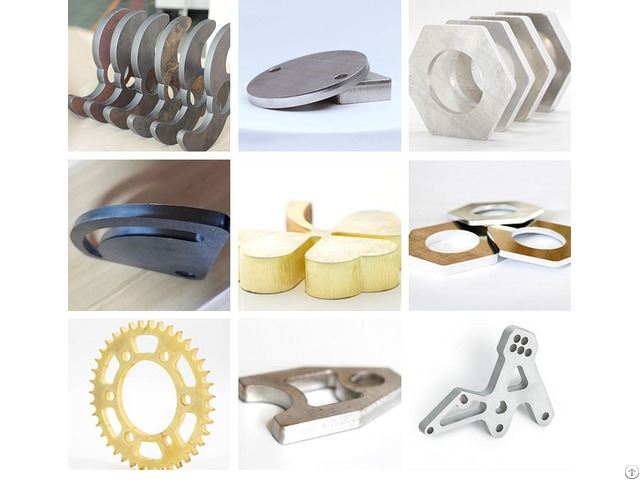

Sheet metal laser cutter applications: Steel laser cutter can carry up to 8000W laser power, so cutting some thick plate, it is a very good choice.

For example, agricultural machinery, textile machinery, food machinery and construction machinery and other large machinery and equipment manufacturing, usually use high power fiber laser cutting machine for processing.

Suitable for stainless steel, carbon steel, silicon steel, aluminum alloy, titanium alloy, galvanized steel, aluminum-plating zinc plate, copper, and other metals.

Company Contact:

- Posted By: IGOLDENCNC

- Phone: 18660188728

- Address: Yu Huang Miao, Shanghe , employment , China

- Email:

- Website: https://www.igoldencnc.com/

Published date: December 5, 2021

- Business Description: We are a company integrating manufacturing and sales of CNC routers, laser engraving machines, laser cutting machines, plasma cutting machines, cutting plotters, etc.

The main configuration all adopt top parts imported from Italy, Japan, Germany, etc.

We adopt international advanced producing technologies to improve our products.

Our products are widely used in advertising, woodworking, artworks, model, electric, CAD/CAM industry models, clothing, package printing, marking, laser sealing and so on.

Our company adheres to the Market-Oriented business principles, and implements the business philosophy of "Quality First and Customer First".

We have set up more than 20 sale and service departments around China which can offer our customers the services of design, fixing, training, maintenance and so on.

Besides sale in China, our products exports around the world including the Middle East, Africa, Europe and the USA.

Related listings

-

New Sheet Metal Cutting MachineFibers and textiles and fabric industries - IGOLDENCNC - China - December 5, 2021 - 15000.00 Dollar US$

New Sheet Metal Cutting MachineFibers and textiles and fabric industries - IGOLDENCNC - China - December 5, 2021 - 15000.00 Dollar US$Run your factory in full efficiency with our full cover fiber laser cutter. The auto-loader and auto parallel pallets system keeps your production flowing without machine stop. It is best for mass cutting of plates and tubes, which saves huge labor c...

-

Cnc Wood Carving MachineFibers and textiles and fabric industries - IGOLDENCNC - China - December 5, 2021 - 15000.00 Dollar US$

Cnc Wood Carving MachineFibers and textiles and fabric industries - IGOLDENCNC - China - December 5, 2021 - 15000.00 Dollar US$CNC wood cutting machine with Siemens CNC controllers provides suitable automation solutions for all machine designs for workshops, contract manufacturing, and mass production.such as CNC, servo drive, motor, and the cable during the warranty period,...

-

Atc Cnc Router Machine PriceFibers and textiles and fabric industries - IGOLDENCNC - China - December 2, 2021 - 25000.00 Dollar US$

Atc Cnc Router Machine PriceFibers and textiles and fabric industries - IGOLDENCNC - China - December 2, 2021 - 25000.00 Dollar US$This atc cnc router machine price Linear auto tool change design, no need to change tool manually. It can help to finish different work quickly. with DSP control system is used for decorations, musical instruments, wood crafts, wood furnitures, wood ...

Safe Trade Tips

- Ask for business references and check them

- Use a payment method that offers better protection for all such as Letters of credit and verified professional escrow services. Avoid payments in advance such as money transfers

- Verify their business via their local Chamber of Commerce

- Search the internet using their website address, their business name, their phone and fax numbers, and their email addresses to see if you can find any feedback about them.

- Get to know more about scams and fraud to avoid: Internet Crime Complaint Center - Consumer Financial Protection Bureau

- This site is never involved in any transaction, and does not handle payments, shipping, guarantee transactions, provide escrow services, or offer "buyer protection" or "seller certification"