Candle Filter - China

price: 20.00 Dollar US$

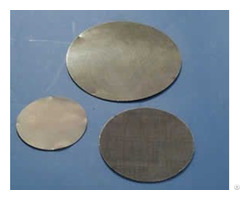

Candle Filters for polymer melt can be pleated in the body with several end types.

Made of woven filter wire mesh cloth or sintered fiber web imported, candle filter elements offer ideal property for polymer melting processing in chemical and fiber industries .

Pleated Candle Filter:

The supportive inner layer is fabricated of galvanized perforated sheet metal.

Galvanized wire mesh is pleated to support the filter media.

For more rigorous applications, a second layer of wire mesh is placed on the outside of the pleated filter media for back washing environments.

Filter media are available in a variety of micron ratings and efficiencies.

Commonly used are polyester felts, woven wire mesh or sintered metal.

Benefits:

The filter media is cleanable at the job site.

Sewn end style filters are used in applications where chemical compatibility and temperature concerns dictate the style of filter.

For more aggressive environments, this style can be constructed with stainless steel parts and high temperature media.

Metal End Cap Filter:

Metal end caps are available in a variety of configurations and styles.

One style consists of one open end and one closed end with a bolt hole, while another variety is a double open end.

Benefits:

Standard construction consists of a perforated or expanded core, made of galvanized carbon steel sheet metal.

These cores surround either a pleated filter media or paper media.

Company Contact:

- Posted By: Boegger Industrial Limited-filter element

- Phone: 863185111380

- Address: East Industrial Zone, Anping, Hebei, China., Hengshui , Hebei , China

- Email:

- Website: https://www.filter-element.org

Published date: October 8, 2016

- Business Description: Boegger manufactures the following types of filter elements:

Hydraulic, designed to equip pressurized filters, filter drain and other hydraulic systems.

Oil intended for lubricating systems, filters, complete machines and mechanisms in various industries.

Fuel intended for the complete fuel filters vehicle engines.

Aircraft designed for air filter assembly vehicle engines and compressors.

Filter elements are manufactured with a nominal fineness of filtration:

Paper - 05, 10, 25 and 40 microns

Net - 40, 80, 120 and 160 microns

Filter elements provide the highest degree of filtration efficiency for industrial, mobile, and process applications.

Our filter elements are composed of micro-glass media, the most recent innovation in high performance filtration technology.

Micro-glass media is inert, inorganic, and far exceeds any paper or cellulose filter element performance.

Water or chemicals, which cause softening, swelling, and degradation in conventional cellulose or pleated paper filters, do not affect micro-glass media.

The advantages of making filter element

Filter elements and filters manufactured have a high technical specification through a number of structural and technological features, chief among them the use of modern materials quality, reliability and stability of the design process.

The use of modern filter materials

Effective is the one filter element, which not only removes dirt but also keeps them securely for the duration of the service.

Depending on the material, the filter elements are divided into two main groups: surface and volume.

Using of filter material has been a very stable structure.

Enhanced binding of the fibers provides a stable bond between the fibers and increases the strength of the material under the influence of load versus load fluctuations of pressure and flow rate, temperature and aging.

With this filter elements maintain its high performance during its entire life.

The filter material is the most important component of the "filter" system with respect to prolonged life and wear protection of the system.

Decisive criteria for the selection are the necessary degree of cleanliness of the operating medium, the initial pressure differential and the contamination retention capacity.

Mount

Fixing filtering curtains, adhesives and potting applied mass is crucial for the efficiency of the filter element.

Through the use of supporting curtains made of nets in combination with one or more filtering curtains, achieved the desired filtration factor, which ensures effective protection of the host machine and increases the life of filter elements.

Stiffness of the frame filter element is provided, where necessary, special reinforcing ring rolling or circular edges.

The stability of the process

The optimal form of corrugated filter media is possible only with a stable automated manufacturing process and strict compliance with technological standards.

In the manufactured quality filter element secured the required number of corrugations, which allows to obtain the optimum filter area and the best performance.

Related listings

-

Wire Mesh StrainersMetal and mineral industries - Boegger Industrial Limited-filter element - China - October 8, 2016 - 20.00 Dollar US$

Wire Mesh StrainersMetal and mineral industries - Boegger Industrial Limited-filter element - China - October 8, 2016 - 20.00 Dollar US$We supply Stainless Steel Wire Mesh Strainers fabricated from woven wire cloth, mainly tea strainers and sink strainers, for kitchen and family uses. The stainless steel material applies: AISI316 and AISI316L. Shapes and sizes: Tailored to meet your ...

-

Liquid Filter ElementMetal and mineral industries - Boegger Industrial Limited-filter element - China - October 8, 2016 - 20.00 Dollar US$

Liquid Filter ElementMetal and mineral industries - Boegger Industrial Limited-filter element - China - October 8, 2016 - 20.00 Dollar US$Liquid filtration is the removal of solids from liquids by flowing the contaminated liquid through a filter medium that will retain the solid particulates and allow only clean liquid to pass through. A liquid filter is designed to remove impurities t...

-

Pleated Filter ElementMetal and mineral industries - Boegger Industrial Limited-filter element - China - October 8, 2016 - 20.00 Dollar US$

Pleated Filter ElementMetal and mineral industries - Boegger Industrial Limited-filter element - China - October 8, 2016 - 20.00 Dollar US$Flow-Max filter cartridges outperform wound, spun, melt blown, resin bonded and other "depth" type filter elements because our cartridges are pleated to provide increased surface area and longer life. Flow-Max filter cartridges outperform other pleat...

Safe Trade Tips

- Ask for business references and check them

- Use a payment method that offers better protection for all such as Letters of credit and verified professional escrow services. Avoid payments in advance such as money transfers

- Verify their business via their local Chamber of Commerce

- Search the internet using their website address, their business name, their phone and fax numbers, and their email addresses to see if you can find any feedback about them.

- Get to know more about scams and fraud to avoid: Internet Crime Complaint Center - Consumer Financial Protection Bureau

- This site is never involved in any transaction, and does not handle payments, shipping, guarantee transactions, provide escrow services, or offer "buyer protection" or "seller certification"