Cold Rolled Aluminum Coil 0 15 4 0mm 1060 1100 3003 3105 5052 - China

price: 3105.00 Dollar US$

Cold rolled aluminum coil usually refers to the cold rolled aluminum coil processed by the cast rolling material through the cold rolling process, which is usually called cast rolled aluminum coil.

Cold rolling is a common metal processing process.

It is to reduce the thickness of the material and improve its surface quality and mechanical properties by further processing at room temperature or slightly below room temperature after the metal is heated (usually hot rolled).

As for the aluminum coil casting process, it may be relatively simple.

Aluminum ingot---aluminum liquid---static furnace---cast rolled coil, which is a conventional processing process for raw materials.

Cold-rolled aluminum coils are more inclined to non-heat treatment processes.

For example, our common 1060 aluminum coils, 3003 aluminum plates, 3105 aluminum coils, 5052 aluminum plates, 1100 aluminum plates, etc.

are all cold-rolled aluminum coils, which are suitable for simple stamping, but not suitable for large-scale finished product stamping.

Therefore, the main application areas are currently mainly concentrated in building exterior walls, signs and signs, etc.

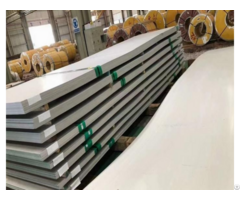

Aluminum coil specifications:

Alloy: 1060, 1100, 3003, 3004, 3105, 5052, 8011, etc

Temperature: H32 H34 H36 H42 H111 H112 H116, etc

Surface: Mill, Bright, Polished, Hairline, Embossed, Etching

Thickness: 0.15-4.0mm

Width: 20-2650mm

Length: C

Core Diameter: 505/508

Sample: Free sample Features of cold-rolled aluminum coil:

1 - High surface finish: The cold rolling process can improve the surface quality of the aluminum coil, making it smooth and shiny.

2 - High thickness accuracy: The thickness of the cold-rolled aluminum coil can be very precise, suitable for applications with strict thickness requirements.

3 - Excellent mechanical properties: The cold rolling process can improve the strength and hardness of aluminum, especially in applications that require high strength.

4 - Good processability: Due to its good strength and ductility, cold-rolled aluminum coils are easy to process in the future, such as shearing, stamping, stretching, etc.

Application areas:

Building materials: used for building materials such as roofs, wall panels, curtain walls, etc.

Automotive industry: body panels, auto parts, etc.

Electronic products: shells of mobile phones, laptops, etc.

Home appliance industry: shell materials for home appliances such as refrigerators and washing machines.

Packaging industry: such as beverage cans, food packaging, etc.

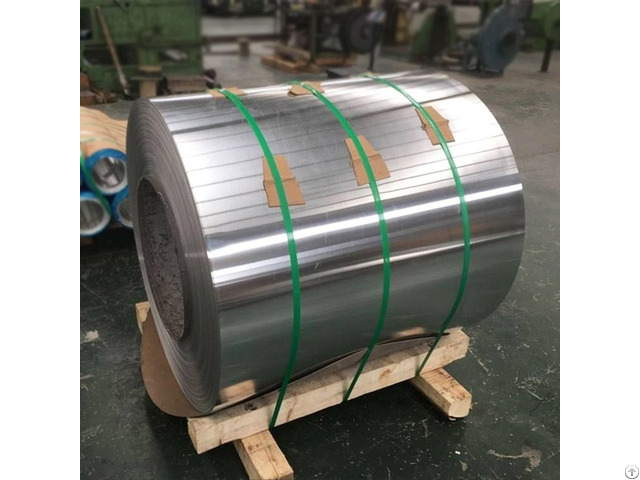

Packaging:

Export packaging of aluminum coils: Export packaging usually adopts the fumigation well frame method, which is fixed with steel belts on the outside.

The aluminum coil has a double-layer moisture-proof rain cloth on the outside, and the inside is protected from moisture-proof agents.

It adopts sealed packaging, which is suitable for sea transportation.

Company Contact:

- Posted By: Henan Hongchang Aluminum Co., Ltd.

- Phone: 18703635966

- Address: No. 14, Business Outer Ring Road, zhengzhou , henan , China

- Email:

- Website: https://www.alummc.com/

Published date: October 15, 2024

- Business Description: Hongchang Aluminum has been specializing in the production of 1-8 series aluminum sheets, foil strips and other products for more than 20 years, such as automotive aluminum sheets, household aluminum foils, anodized aluminum sheets, mirror aluminum sheets, packaging aluminum foil, aluminum pp cover materials, DOS oil-coated aluminum sealing sheets, cookware Aluminum circles, marine aluminum sheets, double-zero aluminum foils, aluminum pattern sheets and other products are widely used in automobiles, ships, food, medical, tankers, electronic equipment, construction, industry and other fields.

Factory direct sales, favorable prices, exported overseas, and guaranteed after-sales service.

Related listings

-

Strong Market Potential Of Solution Aging Treated Ncf600 Alloy MaterialMetal and mineral industries - Dongguan Songshun Mould Steel Co., Ltd. - China - October 14, 2024 - 595.00 Dollar US$

Strong Market Potential Of Solution Aging Treated Ncf600 Alloy MaterialMetal and mineral industries - Dongguan Songshun Mould Steel Co., Ltd. - China - October 14, 2024 - 595.00 Dollar US$heat treatment is an important step to improve the performance of ncf600 alloy material. generally speaking, the heat treatment process of ncf600 includes solution treatment and aging treatment: solution heat treatment: after maintaining a certain pe...

-

Significant Characteristics Of Casting Hot Processing Ncf600 Alloy PipeMetal and mineral industries - Dongguan Songshun Mould Steel Co., Ltd. - China - October 14, 2024 - 594.00 Dollar US$

Significant Characteristics Of Casting Hot Processing Ncf600 Alloy PipeMetal and mineral industries - Dongguan Songshun Mould Steel Co., Ltd. - China - October 14, 2024 - 594.00 Dollar US$the process performance of ncf600 alloy pipe is mainly reflected in its casting, welding and thermal processing capabilities. the alloy has excellent casting properties and can be made into complex parts through smelting and casting techniques. its w...

-

Wide Range Of Applications Ncf600 Alloy Steel Plates Preferred Material Many FieldsMetal and mineral industries - Dongguan Songshun Mould Steel Co., Ltd. - China - October 14, 2024 - 593.00 Dollar US$

Wide Range Of Applications Ncf600 Alloy Steel Plates Preferred Material Many FieldsMetal and mineral industries - Dongguan Songshun Mould Steel Co., Ltd. - China - October 14, 2024 - 593.00 Dollar US$ncf600 alloy steel plates are used in the following areas: 1. thermocouple sleeves in corrosive atmospheres 2. vinyl chloride monomer consumption: resistance to chlorine, hydrogen chloride, oxidation and carbonization corrosion 3. uranium oxidation c...

Safe Trade Tips

- Ask for business references and check them

- Use a payment method that offers better protection for all such as Letters of credit and verified professional escrow services. Avoid payments in advance such as money transfers

- Verify their business via their local Chamber of Commerce

- Search the internet using their website address, their business name, their phone and fax numbers, and their email addresses to see if you can find any feedback about them.

- Get to know more about scams and fraud to avoid: Internet Crime Complaint Center - Consumer Financial Protection Bureau

- This site is never involved in any transaction, and does not handle payments, shipping, guarantee transactions, provide escrow services, or offer "buyer protection" or "seller certification"