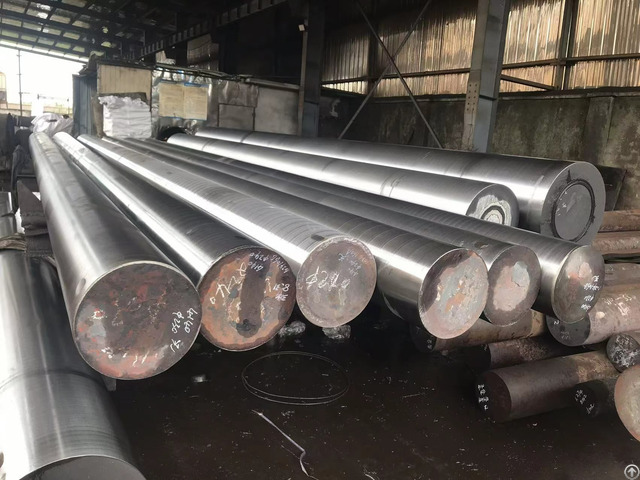

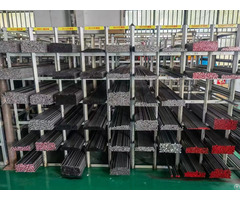

Forging Heat Treating Sae A2 Tool Steel Suppliers Manufacture - China

price: 1066.00 Dollar US$

a2 steel application

the application is decided by a2 steel chemical composition and properties.

it has high hardness and toughness.

the application as below: 1 - precision stamping die.

2 - precision blanking dies for wire cutting and stamping die for various purposes.

3 - cold forging, deep drawing and boring molds.

4 - high-speed punching punch, stainless steel plate punch.

5 - shear and slitter blades.

a2 steel round bar sheet plate heat treatment

stress relieving

after heavy grinding or machine, it is advisable to stress relieve tool steel 1.2363 to reduce the danger of cracking or distortion during subsequent heat treatments.

heat slowly to 670-700°c, soak for a minimum of two hours per 25mm of the section then cool down in the furnace.

annealing

1.2363 tool steels are annealed at 857°c (1575°f) and then cooled slowly in the furnace at a rate of 4°c (40°f) per hour or less.

hardening

preheating temperature: 1200–1380°f (650–750°c).

austenitizing temperature: 1700 –1780°f (925–970°c) but usually 1720–1760°f (940–960°c).

tempering

1.2363 tool steels are heat treated at temperatures ranging from 177°c (350°f) for rockwell c 62 to 538°c (1000°f) for rockwell c 56 and then tempered.

quenching

martempering bath or fluidized bed at 360–430°f (180–220°c) or 840–1020°f (450–550°c) then cool in the air.

circulating air or atmosphere.

vacuum furnace with an overpressure of gas at cooling.

oil (only for small and uncomplicated tools).

nitriding

nitriding will give a hard diffused surface layer which is very resistant to wear and erosion, and also increases corrosion resistance.

nitriding din 1.2363 steels in ammonia gas at a temperature of 975°f (525°c) gives an a2 steel surface hardness of approx.

welding

din 1.2363 tool steels are alloy steels and hence they are capable of being welded.

however, welding of 1.2363 tool steels is not much preferred due to the risk of crack formation.

the following guidelines can be followed during the welding of 1.2363 steels: a.

welding in order to harden the soft annealed 1.2363 tool steel 1 - heat to austenitizing temperature

2 - cool to approx.

500°c (932°f)

3 - weld at approx.

500°c (932°f)

4 - cool to approx.

100°c (212°f)

5 - hard facing electrode b.

repair welding of 1.2363 tool steels in hardened and tempered condition 1 - preheat to the tempering temperature (min.

200°c) (392°f)

2 - weld at the tempering temperature

3 - heat immediately to tempering temperature, but max.

300°c (572°f).

soak the steels for 3 hours

4 - cool in the air to approx.

80°c (176°f)

5 - heat to tempering temperature.

soak for 2 hours

6 - hard facing electrode c.

welding of soft annealed a2 tool steel 1 - preheat to 300-500°c (572-932°f)

2 - weld at 300-500°c (572-932°f)

3 - stress relieve immediately.

4 - cr-mo alloy electrode for welding structural steel heat treatment

a2 tool steels are heated slowly to 788°c (1450°f) and this is followed by increasing the temperature to 954°c (1750°f).

1.2363 tool steels are further held at 954°c (1750°f) for 30 to 45 minutes and finally removed from the furnace and cooled.

machinability

1.2363 tool steels have medium machinability, about 85% that of the w group of tool steels which are rated at 100% for a baseline.

Company Contact:

- Posted By: Dongguan Songshun Mould Steel Co., Ltd.

- Phone: 076985475596

- Address: 1st Floor, No. 1, Dongda Fourth Street, Shatou Community, Chang'an Town, Dongguan , Guangdong , China

- Email:

- Website: https://songshunsteel.com/

Published date: August 3, 2022

- Business Description: Established in 2009,Songshun Steel supplies a wide range of carbon, alloy and tool steel products, including high speed tool steel, cold work tool steel, hot work tool steel, plastic mould steel, engineering steel and machine structural steel etc.

After more than 10 years development and growing, Songshun Steel becomes one comprehensive special steel factory, stockist and exporter.

Combined with experienced exporting team and professional technical knowledge, Songshun Steel offers both technical advice and support, as well as global professional steel solution and service.

Due to satisfactory reliable quality and professional service, Songshun expands our market worldwide, such as Colombia, Chile, Spain, Turkey, Iran, Vietnam, Malaysia ,UAE, Canada, Brazil, Mexico and so on.

Songshun specialized in Special Steel for almost 20 years.

We can supply mold steel, high speed steel, alloy steel, free cutting steel and etc.

Welcome your contact 24 hours a day!!!

Skype/Whatsapp/We chat: +86-18269260283

Songshun Tiktok: mikizhuo

Songshun Facebook: Songshun Steel

Songshun YouTube: MiKi Zhuo

songshunmoldsteel414 04340

Related listings

-

Heat Treatment Din 1 2311 Aisi P20 Steel Round BarMetal and mineral industries - Dongguan Songshun Mould Steel Co., Ltd. - China - August 3, 2022 - check with company for price

Heat Treatment Din 1 2311 Aisi P20 Steel Round BarMetal and mineral industries - Dongguan Songshun Mould Steel Co., Ltd. - China - August 3, 2022 - check with company for pricep20 steel is used to make thermoplastic molds, extrusion dies, injection molds and die casting dies. and can also be used to make main components of heavy-duty mold. in addition, it also be used to produce cold structural parts, tv cases, washing mac...

-

Aisi P20 Steel Suppliers Round Bar Sheet PlateMetal and mineral industries - Dongguan Songshun Mould Steel Co., Ltd. - China - August 3, 2022 - check with company for price

Aisi P20 Steel Suppliers Round Bar Sheet PlateMetal and mineral industries - Dongguan Songshun Mould Steel Co., Ltd. - China - August 3, 2022 - check with company for pricep20 steel round bar sheet plate has many excellent properties. in the pre-hardened status, the mold can be processed without any heat treatment. which cut down the running period and improves efficiency. after it has been processed through the forged...

-

Aisi 4140 Sae 4340 Astm 5140 Steel Plate Supplier Price Per KgMetal and mineral industries - Dongguan Songshun Mould Steel Co., Ltd. - China - August 3, 2022 - 1036.00 Dollar US$

Aisi 4140 Sae 4340 Astm 5140 Steel Plate Supplier Price Per KgMetal and mineral industries - Dongguan Songshun Mould Steel Co., Ltd. - China - August 3, 2022 - 1036.00 Dollar US$1.what we do? we specialized in steel as a professional special steel supplier, and also can give you technical advice and support for your business base on our professional technical knowledge. because of our great and reliable quality and professio...

Safe Trade Tips

- Ask for business references and check them

- Use a payment method that offers better protection for all such as Letters of credit and verified professional escrow services. Avoid payments in advance such as money transfers

- Verify their business via their local Chamber of Commerce

- Search the internet using their website address, their business name, their phone and fax numbers, and their email addresses to see if you can find any feedback about them.

- Get to know more about scams and fraud to avoid: Internet Crime Complaint Center - Consumer Financial Protection Bureau

- This site is never involved in any transaction, and does not handle payments, shipping, guarantee transactions, provide escrow services, or offer "buyer protection" or "seller certification"