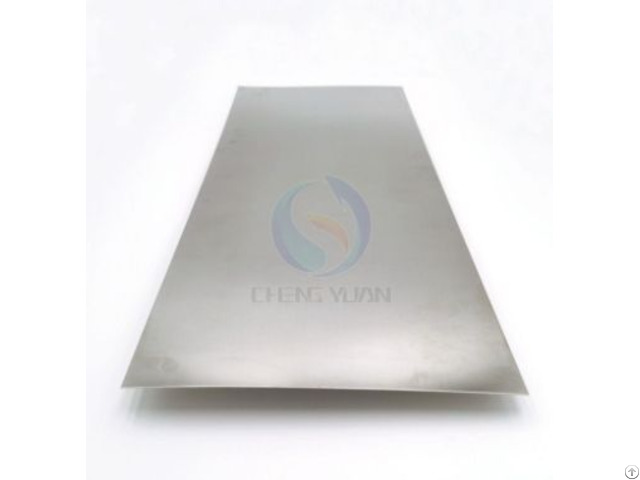

Nickel Base Alloy - China

price: contact company for price

Nickel Base Alloy

The Ultimate Guide to Nickel-Base Alloy: Exploring Its Properties and Applications

Introduction

In the world of materials engineering, Nickel-Base Alloy is a highly regarded and versatile class of alloys that find extensive use in various industries.

These alloys offer exceptional corrosion resistance, high-temperature strength, and excellent mechanical properties, making them indispensable in critical applications.

If you want to wholesale high quality Nickel Base Alloy, you can browse the product details and contact us to get a quote.

Understanding Nickel-Base Alloy

Nickel-Base Alloy, as the name suggests, is an alloy primarily composed of nickel along with other elements, such as chromium, molybdenum, iron, and cobalt.

The addition of these elements imparts specific properties to the alloy, making it highly desirable for a wide range of applications.

The exact composition and ratios of these elements can vary depending on the desired characteristics of the alloy.

Properties of Nickel-Base Alloy

Nickel-Base Alloy exhibits several remarkable properties that contribute to its extensive usage in various industries.

Let's take a closer look at some of its key properties:

i.

Corrosion Resistance

One of the most notable features of Nickel-Base Alloy is its exceptional resistance to corrosion.

This makes it an ideal choice for applications where exposure to corrosive environments, such as acids, alkaline solutions, and seawater, is expected.

The alloy forms a protective oxide layer on its surface, preventing further degradation and ensuring long-term durability.

ii.

High-Temperature Strength

Another significant advantage of Nickel-Base Alloy is its impressive strength and stability at elevated temperatures.

This property makes it suitable for applications that involve high-temperature environments, such as gas turbines, aerospace components, and heat exchangers.

The alloy retains its mechanical integrity even under extreme heat, providing reliability and safety in critical applications.

iii.

Excellent Mechanical Properties

Nickel-Base Alloy boasts excellent mechanical properties, including high tensile strength, good ductility, and favorable impact resistance.

These properties enable the alloy to withstand heavy loads, shocks, and vibrations, making it an optimal choice for structural components subjected to demanding operating conditions.

Applications of Nickel-Base Alloy

The versatile nature of Nickel-Base Alloy opens up a vast array of applications across numerous industries.

Here are some key areas where this alloy is commonly employed:

i.

Aerospace Industry

In the aerospace industry, Nickel-Base Alloy finds extensive use in the manufacturing of aircraft gas turbine engines, combustion chambers, and other critical components.

The alloy's high-temperature strength, corrosion resistance, and excellent creep resistance make it an indispensable material for ensuring safe and efficient flight operations.

ii.

Chemical Processing

Nickel-Base Alloy plays a crucial role in chemical processing plants, where it is utilized in reactors, piping systems, and heat exchangers.

Its ability to withstand highly corrosive environments and maintain mechanical stability under extreme temperatures makes it a preferred choice for handling aggressive chemicals.

iii.

Oil and Gas Industry

In the oil and gas sector, Nickel-Base Alloy is widely employed for equipment exposed to harsh environments, including offshore platforms and refineries.

The alloy's resistance to corrosion, erosion, and cracking makes it suitable for applications such as downhole tubing, valves, and heat exchangers.

iv.

Power Generation

Nickel-Base Alloy is extensively used in power generation facilities, including nuclear power plants and gas turbines.

Its exceptional high-temperature strength, resistance to corrosion, and creep resistance make it an ideal material for critical components like turbine blades, steam generators, and reactor vessels.

Company Contact:

- Phone: 13673186216

- Address: First floor, Grui Building, No. 227, South Tiyu Street, Yuhua District, Shijiazhuang , Hebei Sheng, China

- Email:

Published date: September 12, 2023

- Business Description: Shijiazhuang Chengyuan Alloy Material Co., Ltd. has been engaged in the alloy material industry for more than 10 years.

It is a high-tech enterprise specializing in the production of various alloy materials.

It is located in Shijiazhuang City, Hebei Province.

It is adjacent to Beijing and Tianjin.

It has developed transportation and convenient transportation.

The company focuses on the production and supply of various types of electric alloys, expansion alloys, soft magnetic alloys, elastic alloys, high temperature alloys, and all kinds of pure metals.

Seamless pipes, silk mesh, powder, etc.

can meet the application needs of different customers.

Products are widely used in heating equipment, machinery manufacturing, electric furnace production, instrumentation, household appliances, automobile industry, aerospace industry.

We are familiar with the production standards and application environments of each country, which can meet customer custom requirements and give reasonable suggestions.

If customers make non-standard requirements, they can also be implemented.

-Resistance Heating Alloy

-Metallic Functional Material

-Superalloys

-El ectronic Product Accessories

Related listings

-

P20 Ni Steel Application Ideal Material For Many FieldsMetal and mineral industries - Dongguan Songshun Mould Steel Co., Ltd. - China - September 11, 2023 - check with company for price

P20 Ni Steel Application Ideal Material For Many FieldsMetal and mineral industries - Dongguan Songshun Mould Steel Co., Ltd. - China - September 11, 2023 - check with company for pricein the field of mold manufacturing, p20+ni steel has been widely used. because of its high hardness and wear resistance, it can withstand work under high pressure, friction and high temperature environment, and it can meet various shape and size requ...

-

Plastic Mold Steel Aisi P20 Ni Material ProductionMetal and mineral industries - Dongguan Songshun Mould Steel Co., Ltd. - China - September 11, 2023 - 77.00 Dollar US$

Plastic Mold Steel Aisi P20 Ni Material ProductionMetal and mineral industries - Dongguan Songshun Mould Steel Co., Ltd. - China - September 11, 2023 - 77.00 Dollar US$1. prepare raw materials before the smelting stage of aisi p20+ni steel, the first step is to select suitable high-quality raw materials. the content of elements will directly affect the performance of the steel, so it is necessary to strictly contro...

-

Good Corrosion Resistance 1 2738 P20 Ni Steel FabricationMetal and mineral industries - Dongguan Songshun Mould Steel Co., Ltd. - China - September 11, 2023 - check with company for price

Good Corrosion Resistance 1 2738 P20 Ni Steel FabricationMetal and mineral industries - Dongguan Songshun Mould Steel Co., Ltd. - China - September 11, 2023 - check with company for price1. prepare raw materials the supplier of songshun p20+ni steel first analyzes the advantages of p20+ni steel, mainly from the following aspects. (1) in terms of performance, p20+ni has good corrosion resistance and wear resistance, high strength, hig...

Safe Trade Tips

- Ask for business references and check them

- Use a payment method that offers better protection for all such as Letters of credit and verified professional escrow services. Avoid payments in advance such as money transfers

- Verify their business via their local Chamber of Commerce

- Search the internet using their website address, their business name, their phone and fax numbers, and their email addresses to see if you can find any feedback about them.

- Get to know more about scams and fraud to avoid: Internet Crime Complaint Center - Consumer Financial Protection Bureau

- This site is never involved in any transaction, and does not handle payments, shipping, guarantee transactions, provide escrow services, or offer "buyer protection" or "seller certification"