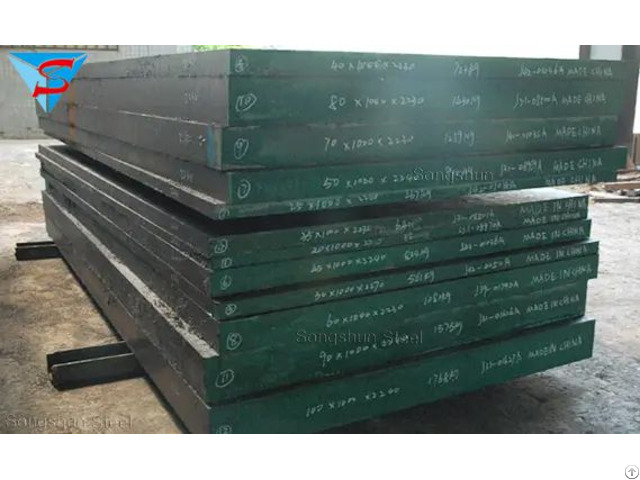

S7 Tool Steel Round Bar Sheet Plate Material - China

price: 400.00 Dollar US$

aisi s7 tool steel be made of chromium-molybdenum alloy to satisfy the needs of high impact toughness.

the chemical composition of cr is quite high.

so it has good tempering resistance, high-temperature oxidation, wire-electrode cutting property and impact toughness.

after annealing softening treatment, the rolling steel bar must take the process of heating before the use.

because of the higher toughness and high-temperature oxidation, s7 steel material is widely used in the plastic mold, cold work and hot work tools that working in the high temperature and impact condition.

s7 steel application

what is s7 steel used for? punch

forging die

hammer

chisel

cutting tools

small plastic molds

gripper dies

swaging dies

shear blades

hot work and cold work mold

blanking dies

drills

drill plates s7 steel round bar sheet plate heat treatment

annealing

start by quickly heating to 1500 to 1550°f and hold at that temperature for an hour and a half.

it is then slowly cooled to 1000°f followed by air cooling, this is for optimum processability.

this annealing procedure should produce a maximum brinell hardness of 197 - stress relief s7 steel material: when required to relieve machining strain, heat slowly to 1050°-1250°f, allow to equalize, then cool in air.

hardening

preheating: before hardening, s7 steel is heated slightly before being loaded into a preheat furnace at 1200°-1300°f.

hardening: 1750°f.

air quench if cross section is 2-1/2″ or smaller; 2-1/2″ through 6″ sections should be oil quenched to black (1000°f) then air cooled to 150°f.

larger cross-sections of s7 steel shall be oil quenched to 150°f.

quenching

quenching in still or dry air.

tempering

tool steel s7 is typically tempered for one hour per inch of section thickness to achieve the required heating rate of 2 hours per inch.

cool in air to room temperature between states.

tempering temperatures vary according to intended use.

recommended: 400°-500°f for cold work applications.

thermal processing applications from 900°-1000°f.

forging

first preheat to 1200°-1300°f, forge at 2000°-2050°f, then stop at 1700°f and cool slowly.

songshun specialized in special steel for almost 20 years.

we can supply mold steel, high speed steel, alloy steel, free cutting steel and etc.

welcome your contact 24 hours a day!!!songshunsteel202401 15

Company Contact:

- Posted By: Dongguan Songshun Mould Steel Co., Ltd.

- Phone: 076985475596

- Address: 1st Floor, No. 1, Dongda Fourth Street, Shatou Community, Chang'an Town, Dongguan , Guangdong , China

- Email:

- Website: https://songshunsteel.com/

Published date: April 29, 2024

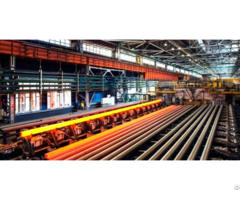

- Business Description: Established in 2009,Songshun Steel supplies a wide range of carbon, alloy and tool steel products, including high speed tool steel, cold work tool steel, hot work tool steel, plastic mould steel, engineering steel and machine structural steel etc.

After more than 10 years development and growing, Songshun Steel becomes one comprehensive special steel factory, stockist and exporter.

Combined with experienced exporting team and professional technical knowledge, Songshun Steel offers both technical advice and support, as well as global professional steel solution and service.

Due to satisfactory reliable quality and professional service, Songshun expands our market worldwide, such as Colombia, Chile, Spain, Turkey, Iran, Vietnam, Malaysia ,UAE, Canada, Brazil, Mexico and so on.

Songshun specialized in Special Steel for almost 20 years.

We can supply mold steel, high speed steel, alloy steel, free cutting steel and etc.

Welcome your contact 24 hours a day!!!

Skype/Whatsapp/We chat: +86-18269260283

Songshun Tiktok: mikizhuo

Songshun Facebook: Songshun Steel

Songshun YouTube: MiKi Zhuo

songshunmoldsteel414 04340

Related listings

-

Songshun Produces High Quality Steel Products Spot SupplyMetal and mineral industries - Dongguan Songshun Mould Steel Co., Ltd. - China - April 29, 2024 - 900.00 Dollar US$

Songshun Produces High Quality Steel Products Spot SupplyMetal and mineral industries - Dongguan Songshun Mould Steel Co., Ltd. - China - April 29, 2024 - 900.00 Dollar US$steel production best steel products songshun steel produces high-quality steel products, provides all kinds of high-end steel products for construction machinery manufacturing industry, automobile industry, home appliance industry, petrochemical ind...

-

China’s Quality Assured Stainless Steel Fabricators InspectionMetal and mineral industries - Dongguan Songshun Mould Steel Co., Ltd. - China - April 29, 2024 - 888.00 Dollar US$

China’s Quality Assured Stainless Steel Fabricators InspectionMetal and mineral industries - Dongguan Songshun Mould Steel Co., Ltd. - China - April 29, 2024 - 888.00 Dollar US$stainless steel fabricators inspection provide high quality stainless steel as one of china’s quality-assured stainless steel manufacturers, songshun takes high quality as the first standard for our production. we provide a full range of testing serv...

-

Stainless Steel Raw Materials And Steelmaking Smelting ProcessMetal and mineral industries - Dongguan Songshun Mould Steel Co., Ltd. - China - April 29, 2024 - 700.00 Dollar US$

Stainless Steel Raw Materials And Steelmaking Smelting ProcessMetal and mineral industries - Dongguan Songshun Mould Steel Co., Ltd. - China - April 29, 2024 - 700.00 Dollar US$raw materials and steelmaking prepare high-quality raw materials according to customer needs, it undergoes screening, cleaning, drying, batching and other processing. it is usually composed of iron, chromium, nickel and other alloy elements. then an ...

Safe Trade Tips

- Ask for business references and check them

- Use a payment method that offers better protection for all such as Letters of credit and verified professional escrow services. Avoid payments in advance such as money transfers

- Verify their business via their local Chamber of Commerce

- Search the internet using their website address, their business name, their phone and fax numbers, and their email addresses to see if you can find any feedback about them.

- Get to know more about scams and fraud to avoid: Internet Crime Complaint Center - Consumer Financial Protection Bureau

- This site is never involved in any transaction, and does not handle payments, shipping, guarantee transactions, provide escrow services, or offer "buyer protection" or "seller certification"