Specific Application Of Aluminum Alloy In Aviation - China

price: 3000.00 Dollar US$

The application of aluminum alloy in the aviation field has a long history.

This is because aluminum alloy can achieve high strength after heat treatment, but the weight is very light; it is very easy to bend and machined, and it is low in cost.

It is precisely because of these that it has become the most commonly used material in modern aviation and is widely used in the manufacture of modern commercial aircraft and military aircraft, such as Boeing 777, Airbus A380, Boeing's UCAV-unmanned aerial combat aircraft and Boeing F/A -18E/F Generally speaking, the aluminum alloys used as structural parts of aircraft are heat-treatable, such as 2XXX series, 6XXX series, and XXX series groups.

Among them, 7XXX series aluminum alloys, such as 7075, 7040, and 7050 group alloys, occupy the most important position in aviation aircraft components.

Some Al-Li alloys, such as 2090 and 8090, have also been used.

These alloys are widely used, first of all, because they are the most common and extremely easy to form.

In addition, high strength and high corrosion resistance can be obtained after heat treatment.

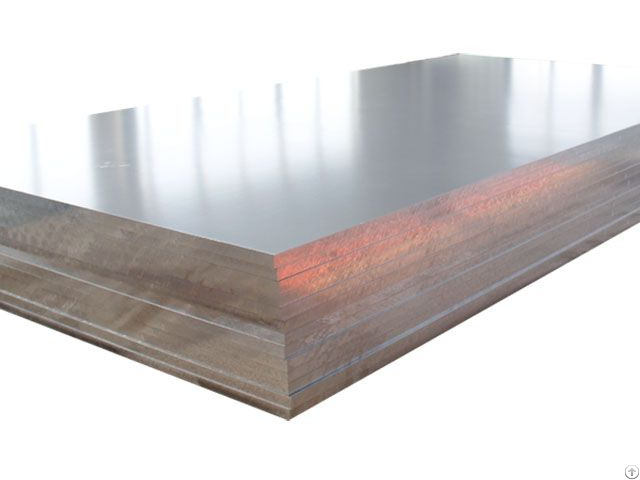

The most commonly used is the 7XXX series forged aluminum alloy, the thickness of the parts can range from 0.6 mm to 250 mm.

7075, 7050 aluminum alloy die castings are widely used in the longitudinal members and structural parts of semi-monocoque aircraft, and some 2024 and 2014 aluminum alloy die castings are also used in the same application.

Thin, double-coated and uncoated 2024, 7475 and 7075 aluminum alloys can be used to make wing and fuselage skins.

Thin plates can be formed into bulkheads and other structural parts by forming and combining.

For heavy-duty aircraft, especially military aircraft, large 7075 and 7040 forgings are the most commonly used.

Recently, people pay more attention to how to make 7075 and 7040 alloy plate forgings the lowest cost through heat treatment.

Manufacturers of aircraft skeletons have tried in the manufacture of such aluminum plates (heat treatment while aluminum is rolled), which are assembled into large ribs and bulkheads after heavy machining.

The advantage of this process is to avoid heat treatment of small parts first and better control of deformation and residual stress, but the disadvantage is that the performance will change along the thickness of the aluminum plate.

However, this change has been studied in detail, and the change of the microstructure along the thickness of the aluminum plate has been further studied.

Castings are sometimes used due to equipment capabilities, but their applications are limited because of the limited design and toughness of the castings.

Typical cast aluminum alloys such as A356 and A357 have been used in similar applications, but they are generally used in the casting of small, atypical aircraft parts, such as door handles and avionics boxes.

When designing an aircraft, the selected structural material should have high specific strength and specific rigidity to reduce the structural weight of the aircraft, improve flight performance or increase economic benefits, and should have good machinability to facilitate the production of required parts.

Simply put, because aluminum alloy is light in weight, high in strength, easy to process, and relatively cheap, all kinds of aircraft use aluminum alloy as the main structural material.

The skins, beams, ribs, stringers, bulkheads and landing gear on the aircraft can all be made of aluminum alloy.

The aluminum alloy used in the aviation field is usually called aviation aluminum alloy, which has a series of advantages such as high specific strength, good processing and formability, low cost and good maintainability, and is widely used in aircraft main structure materials.

In the future, the design requirements of the new generation of advanced aircrafts such as flight speed, structural weight reduction and stealth will be improved, and the specific strength, specific stiffness, damage tolerance performance, manufacturing cost and structural integration of aviation aluminum alloy will be greatly enhanced.

Company Contact:

- Posted By: Mingtai AL industry

- Phone: 18538303430

- Address: No.6, Changchun Road, High-tech district, Zhengzhou City, zhengchou , China

- Email:

- Website: https://www.aluminumsuppiler.com/

Published date: December 4, 2020

- Business Description: Founded in 1997, Henan Mingtai Aluminum Co., Ltd. is a large-scale listed aluminum processing company [stock code: 601677].

The company is mainly engaged in the research, production and sales of 1xxx -8xxx aluminum sheet plates, aluminum strips and aluminum foils.

Related listings

-

Aluminum Plate 5a06 IntroductionMetal and mineral industries - Mingtai AL industry - China - November 24, 2020 - 2000.00 Dollar US$

Aluminum Plate 5a06 IntroductionMetal and mineral industries - Mingtai AL industry - China - November 24, 2020 - 2000.00 Dollar US$5A06 aluminum plate is Al-Mg series rust-proof aluminum. 5A06 aluminum plate has high strength and corrosion stability, and its plasticity is good in annealed and extruded state. The air tightness and plasticity of the weld seam by argon arc welding ...

-

Aluminum Tread Sheet Checker PlateMetal and mineral industries - Mingtai AL industry - China - November 22, 2020 - 2000.00 Dollar US$

Aluminum Tread Sheet Checker PlateMetal and mineral industries - Mingtai AL industry - China - November 22, 2020 - 2000.00 Dollar US$This Aluminum tread plate can be processed by sheet metal processing and spraying process, and can be processed into flat, folded, and curved panels; construction and installation are convenient. Various colors can be sprayed according to customer ne...

-

Aluminum Resources Become A Booster Of Low Carbon EconomyMetal and mineral industries - Mingtai AL industry - China - November 13, 2020 - 10.00 Dollar US$

Aluminum Resources Become A Booster Of Low Carbon EconomyMetal and mineral industries - Mingtai AL industry - China - November 13, 2020 - 10.00 Dollar US$In recent years, the term "low-carbon economy" has frequently appeared in the eyes of consumers. Both policies and regulations and the general public have made great efforts to focus on the term "low-carbon". In daily life, policies encourage everyon...

Safe Trade Tips

- Ask for business references and check them

- Use a payment method that offers better protection for all such as Letters of credit and verified professional escrow services. Avoid payments in advance such as money transfers

- Verify their business via their local Chamber of Commerce

- Search the internet using their website address, their business name, their phone and fax numbers, and their email addresses to see if you can find any feedback about them.

- Get to know more about scams and fraud to avoid: Internet Crime Complaint Center - Consumer Financial Protection Bureau

- This site is never involved in any transaction, and does not handle payments, shipping, guarantee transactions, provide escrow services, or offer "buyer protection" or "seller certification"