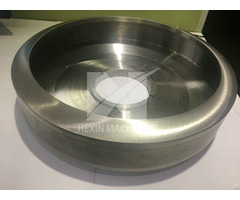

Incinerator Grate Bars - China

price: 500.00 Dollar US$

The incinerator grate bars are made by lost wax investment casting method, with heat resistant stainless steel material, by aluminum mould.

With over 30 year experience with investment castings, our skilled foundry engineers always design the most suitable gating system to guarantee the inside quality of castings.

We supply various components for incineration plant furnaces, like air cooled incinerator grates, water cooled incinerator grate bars, front panels, side wall, guide beams, combustion grates, roof components, etc., 1.

The grate system is the core part of the grate type waste incinerator.

It plays a vital role in the overall process route, incineration effect, project cost, economic benefit, etc.

The waste incineration grate is mainly composed of reciprocating moving parts.

The garbage is pushed onto the grate through the feeding device, heated at high temperature in the furnace, so that part of the garbage can be dried, and the garbage is pushed forward by the movement of the grate.

At the same time, the garbage layer is loosened, and the fuel (garbage) is gradually passed through the various stages of drying, ignition, burning, and burnout to make it completely burnt.

2.

The mechanical grate type incinerator has a variety of grate forms.

Currently, the main applications include reverse push type grate, forward push type grate, drum type grate, etc.

; its main function is the reciprocating mechanical movement of the grate.

Drive the movement and turnover of domestic garbage.

At present, the mechanical grate type incinerators mainly used at home and abroad include Germany's Martin grate furnace technology, Japan's Hitachi Shipbuilding grate furnace technology, etc.

These technologies have different structures and characteristics in their core grate parts.

3.

Compared with fluidized bed and rotary kiln incinerators, mechanical grate incinerators feature perfect and reliable technology, large capacity, strong adaptability to waste, and convenient operation and maintenance.

Company Contact:

- Posted By: Qingdao Hexin Machinery Co.,Ltd

- Phone: 13625328279

- Address: Bei An Industrial park,jimo district,Qingdao,China, Qingdao , China

- Email:

- Website: https://www.hexinmachinery.com/

Published date: March 10, 2021

- Business Description: Qingdao Hexin Machinery is professional for manufacturing,sale and research of high temperature alloy castings,like centrifugal cast tube,investment casting cast heat treatment fixtures,tube sheets,heat resistant cast pipe fitting,ect.

Our foundry has more than 400 staff,including nearly fifty people of engineering and technical personnel,covering an area of 40,000 square meters with the construction area of 25,000 square meters.

Our company is the production base of heat resistant steel and high temperature alloy products.

Our company has passed ISO9002 international quality system to ensure zero defects.

Related listings

-

Jyg Customizes Precision Casting Construction HardwareCastings and casting assemblies - Shandong JYG Precision Casting Co., Ltd - China - March 3, 2021 - 30.00 Dollar US$

Jyg Customizes Precision Casting Construction HardwareCastings and casting assemblies - Shandong JYG Precision Casting Co., Ltd - China - March 3, 2021 - 30.00 Dollar US$Shandong JYG Precision Casting is specialized in precision casting, investment casting, lost wax casting and shell mold sand casting products of thin-wall, intricate geometry. Shandong Jingyanggang Metal Equipment Co., Ltd. (also called JYG Precision...

-

Cobalt Nickel Alloy Spinner Discs CastingCastings and casting assemblies - Qingdao Hexin Machinery Co.,Ltd - China - March 3, 2021 - 200.00 Dollar US$

Cobalt Nickel Alloy Spinner Discs CastingCastings and casting assemblies - Qingdao Hexin Machinery Co.,Ltd - China - March 3, 2021 - 200.00 Dollar US$The spinner discs is a key component of the fiberizer. It is a metal disc with an arc-shaped side wall and thousands of small holes on its surface. The spinner discs part rotates at high speed during use. Under the action of centrifugal force, the gl...

-

Fused Silica PowderCastings and casting assemblies - Buntrock International Pvt Ltd - India - November 27, 2020 - contact company for price

Fused Silica PowderCastings and casting assemblies - Buntrock International Pvt Ltd - India - November 27, 2020 - contact company for priceFused silica is made of high purity crystal silica by electrically fusing (fusing temperature 1800-2000℃) to amorphous Silicon dioxide, then it is classed to different grades by manual and then specially engineered to powder by ball mill. Application...

Safe Trade Tips

- Ask for business references and check them

- Use a payment method that offers better protection for all such as Letters of credit and verified professional escrow services. Avoid payments in advance such as money transfers

- Verify their business via their local Chamber of Commerce

- Search the internet using their website address, their business name, their phone and fax numbers, and their email addresses to see if you can find any feedback about them.

- Get to know more about scams and fraud to avoid: Internet Crime Complaint Center - Consumer Financial Protection Bureau

- This site is never involved in any transaction, and does not handle payments, shipping, guarantee transactions, provide escrow services, or offer "buyer protection" or "seller certification"