High Quality Din 1 2312 Steel Manufacturing Process - China

price: check with company for price

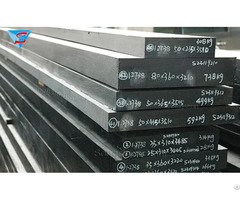

1.2312 steel is a high performance mold steel, which is widely used in the fields of dies, automatic machinery and aviation.

in songshun steel, we continue to break through the 1.2312 steel manufacturing process.

we have a professional and complete manufacturing process for 1.2312 materials, and can produce more high-quality, high-performance 1.2312 mold steel, meeting the application requirements of 2312 steel in parts with high strength, toughness, stability, and impact resistance.

in the manufacturing process of 1.2312 steel, the process of electric furnace melting and vacuum treatment (vacuum degassing and refining to treat pure steel) is usually used.

the 1.2312 steel manufacturing process is complicated, mainly including the following steps: 1 - procurement and selection of raw materials

in order to ensure the chemical composition and performance of 1.2312 steel, the quality of raw materials is strictly controlled through chemical analysis, physical performance testing and other methods, and high-quality raw materials that meet the requirements of the standards are used.

special attention should be paid to the rationality and uniformity of its composition, and there should be no excessive more impurities, improve the purity of steel, which is beneficial to subsequent heat treatment and processing.

2 - melting process

in the 1.2312 steel manufacturing process, the smelting process is the most basic process technology and one of the most complicated processes, which requires professional personnel to analyze and operate.

first, put appropriate amount of raw materials into electric furnace or vacuum furnace for melting and refining treatment.

for some thicker modules or forgings, we usually use converter as the main, intermediate frequency furnace and electric arc furnace as supplementary.

no matter what kind of furnace is used for smelting, the temperature in the furnace, the holding time and the content and proportion of alloying elements must be strictly controlled.

and we have also achieved a more efficient and stable molten steel smelting process and improved the internal quality of 2312 steel by improving furnace design, improving furnace temperature control accuracy, and optimizing smelting parameters.

3 - casting process

in the steel forming process, in addition to the casting process, there is also a forging process.

in our 1.2312 steel manufacturing process, the casting process is usually used.

although the casting process has certain technical difficulties, the use of this process can not only reduce the cost but also form it at one time.

moreover, in addition to die casting, billets can also be continuously cast.

continuous casting technology is an advanced technology that directly pours molten steel into shape.

the continuous casting machine is mass-produced, continuous casting, and low cost.

whether it is mold casting or continuous casting, we adopt advanced pouring technology, control the system design and pouring speed, etc., so as to reduce the occurrence of internal defects of the billet, and obtain billets with precise dimensions and uniform internal structure.

4 - heat treatment process

heat treatment is one of the most important processes in the 1.2312 steel manufacturing process, including steps such as heating, heat preservation and cooling.

through annealing, the hardness of din 1.2312 steel can reach 235hbs, after quenching and tempering, the hardness is 28-35hrc.

in order to better improve the performance and quality of 1.2312 steel and make the grain boundary structure of 2312 steel denser and harder, songshun steel works combines advanced equipment and technology to optimize the heating, heat preservation and cooling process, and strictly controls the heating temperature, holding time and cooling rate.

5 - surface treatment process

the surface treatment of 1.2312 materials includes processes such as drilling, pickling, milling, turning, polishing and phosphating.

through the surface treatment of 1.2312 steel, the surface quality, precision and smoothness of the material are improved.

for example, by soaking 1.2312 steel in acidic solution for pickling, oxides, rust and other impurities on the surface can be removed to achieve the purpose of cleaning the surface and improving the finish.

songshun specialized in special steel for almost 20 years.

we can supply mold steel, high speed steel, alloy steel, free cutting steel and etc.

welcome your contact 24 hours a day!!!

songshun tiktok: songshunsteelfacto ry

songshun facebook: songshun steel

songshun twitter: songshun steel

songshun youtube: songshun steel

songshun company website: https: //songshunsteel.

com/

songshunsteel414043401

Company Contact:

- Posted By: Dongguan Songshun Mould Steel Co., Ltd.

- Phone: 076985475596

- Address: 1st Floor, No. 1, Dongda Fourth Street, Shatou Community, Chang'an Town, Dongguan , Guangdong , China

- Email:

- Website: https://songshunsteel.com/

Published date: August 27, 2023

- Business Description: Established in 2009,Songshun Steel supplies a wide range of carbon, alloy and tool steel products, including high speed tool steel, cold work tool steel, hot work tool steel, plastic mould steel, engineering steel and machine structural steel etc.

After more than 10 years development and growing, Songshun Steel becomes one comprehensive special steel factory, stockist and exporter.

Combined with experienced exporting team and professional technical knowledge, Songshun Steel offers both technical advice and support, as well as global professional steel solution and service.

Due to satisfactory reliable quality and professional service, Songshun expands our market worldwide, such as Colombia, Chile, Spain, Turkey, Iran, Vietnam, Malaysia ,UAE, Canada, Brazil, Mexico and so on.

Songshun specialized in Special Steel for almost 20 years.

We can supply mold steel, high speed steel, alloy steel, free cutting steel and etc.

Welcome your contact 24 hours a day!!!

Skype/Whatsapp/We chat: +86-18269260283

Songshun Tiktok: mikizhuo

Songshun Facebook: Songshun Steel

Songshun YouTube: MiKi Zhuo

songshunmoldsteel414 04340

Related listings

-

Hot Sale P20 Ni 1 2738 Steel Factory Manufacturer SupplyForgings - Dongguan Songshun Mould Steel Co., Ltd. - China - July 31, 2023 - check with company for price

Hot Sale P20 Ni 1 2738 Steel Factory Manufacturer SupplyForgings - Dongguan Songshun Mould Steel Co., Ltd. - China - July 31, 2023 - check with company for price1.2738 steel application gb 3cr2mnnimo / astm p20+ni / din 1.2738 steel is widely used in various mold manufacturing due to its outstanding properties, such as plastic molds, die-casting molds, hot-pressing molds, cold heading molds, etc. it is also ...

-

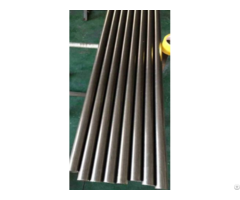

Factory Jis Skh59 High Speed Steel Round Bar StockForgings - Dongguan Songshun Mould Steel Co., Ltd. - China - June 13, 2023 - 789.00 Dollar US$

Factory Jis Skh59 High Speed Steel Round Bar StockForgings - Dongguan Songshun Mould Steel Co., Ltd. - China - June 13, 2023 - 789.00 Dollar US$jis skh59 steel round bar sheet plate heat treatment and produced 1.machinability it can be drilled, turned, threaded, broached, milled and tapped when it is in its annealed condition and rated at 45% of 1% carbon steel. 2.forging it is preheated to ...

-

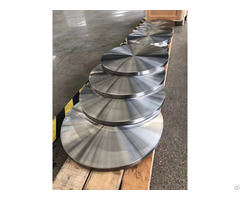

Astm B381 Titanium DiskForgings - Baoji Jufuti non-ferrous metals co,ltd - China - May 15, 2023 - 16.00 Dollar US$

Astm B381 Titanium DiskForgings - Baoji Jufuti non-ferrous metals co,ltd - China - May 15, 2023 - 16.00 Dollar US$ASTM B381 is a specification for titanium forgings, which includes titanium disks. A titanium disk is a circular piece of metal that has been forged or machined from a titanium billet. The disks can be used in various applications, including aerospac...

Safe Trade Tips

- Ask for business references and check them

- Use a payment method that offers better protection for all such as Letters of credit and verified professional escrow services. Avoid payments in advance such as money transfers

- Verify their business via their local Chamber of Commerce

- Search the internet using their website address, their business name, their phone and fax numbers, and their email addresses to see if you can find any feedback about them.

- Get to know more about scams and fraud to avoid: Internet Crime Complaint Center - Consumer Financial Protection Bureau

- This site is never involved in any transaction, and does not handle payments, shipping, guarantee transactions, provide escrow services, or offer "buyer protection" or "seller certification"