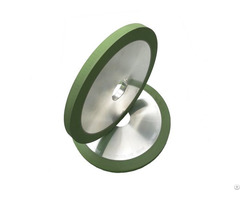

Diamond And Cbn Grinding Wheel For Cnc Machine - China

price: 80.00 Dollar US$

JR diamond tools is an experienced manufacturer of High Quality Diamond and CBN grinding wheels.

JR diamond tools company supplies the wheels for several applications:

Carbide Round tools on CNC machines: Flute Grinding, Gash Grinding, end facing, Clearance angle Cylindrical grinding.

Insert grinding for machines such as: AGATHON, WENDT, HAAS, WAIDA and EWAG.

Woodworking saws and tools.

HSS tools.

Cut off wheels.

STORAGE

Diamond and CBN grinding wheels should be carefully stored in original packaging and the core should be kept oiled.

MACHINES

Machines should be in good working condition, well maintained and free of vibration.

Special attention should be given to the spindle which should run true and the spindle bearings which should be in good condition.

WHEEL MOUNTING

After cleaning and checking the mounting arbor and flange, the wheel should be running true to within 0.02 mm.

COOLANT

• Synthetic oil – Most popular

• Emulsion (water based)

Water with an added rust inhibitor is sufficient for diamond grinding wheels.

The life of CBN grinding tools can be significantly extended by using pure oil yet an emulsion with oil concentration should be sufficient.

CUTTING FLUIDS

Cutting fluids should be used whenever possible when using diamond wheels, to reduce the heat generated by grinding as well as to extend the wheel’s life.

If it’s necessary to dry grind, a corret resin-bond wheel should be used.

COOLANT FLOW

The best cooling effect is achieved when the outlet speed of the cooling lubricant is adapted to the peripheral speed of the grinding wheel, and the nozzle opening is only slightly wider than the grinding rim.

A small trickle of coolant occasionally applied, is better than no coolant at all.

This causes alternate heating and quenching, which can cause damage to the diamond wheel and carbide tools.

FLUTE GRINDING

Grinding wheels used: 1A1, 1V1, 14A1, 14V1, 3A1, 3V1

As flute grinding accounts for the majority of grinding time it is essential to optimise the machine, cooling systems and grinding wheels.

POMDI has developed a new hybrid bonding agent that removes high volumes at material at high operating speeds whilst minimising grinding wheel wear.

This bonding agent also lowers energy consumption.

RELIEF AND GASH GRINDING

Grinding wheels used: 12V9, 1V1, 14V1

This process also sometimes needs to remove a lot of material.

Consequently, the objective is to maximise cutting capacity whilst minimising grinding wheel wear.

CLEARANCE ANGLE AND OUTER DIAMETER

Grinding wheels used: 11V9, 6A9, 6V5, 11A2, 12A2, 11V5, 12V5, 12V2

Clearance angles are used on the face and around the lip to reduce the contact surface between the tool and the workpiece during drilling or milling.

Company Contact:

- Posted By: JR diamond tools Co.,Ltd

- Phone: 86-020-31105688

- Address: Building C28, Huachuang Industrial Park, Jinshan Avenue, Shiji Town, Panyu,, Guangzhou , Guangdong , China

- Email:

- Website: http://www.jrdiamondtoolsgroup.com

Published date: September 17, 2019

- Business Description: JR Diamond Tools Co., Ltd. was established in 2005, and was known as Henan Runfa Superhard Materials Factory established in 1992 - With more than 20 years of researching and developing on super hard materials, it has developed into one of the leading enterprises of super hard material industry in China.

By our strong R&D teams, strict quality control systems, powerful domestic and foreign sales network, our products have covered stone, ceramic, glass, precious stone, diamond, hard metal, and constantly expanded to the photoelectric high-tech fields such as automotive components, precision mechanical parts, electronic and optical glass.

JR company has got ISO certification from TUV NORD CERT GmbH.

‘Elaborate craftsmanship, firm faith based is our business philosophy, we will continue to create new value for you by right of our outstanding products and perfect services.

Related listings

-

Electroplated Diamond Cbn WheelGrinding and polishing and smoothing materials - JR diamond tools Co.,Ltd - China - September 17, 2019 - 80.00 Dollar US$

Electroplated Diamond Cbn WheelGrinding and polishing and smoothing materials - JR diamond tools Co.,Ltd - China - September 17, 2019 - 80.00 Dollar US$Electroplated grinding wheels with nickel bonding can achieve high stock removal rates and high-precision profiles on parts being ground. Depending on the wheel blank design, plating technique, and post-treatment of the single-layer grit structure, m...

-

Resin Bond Diamond WheelsGrinding and polishing and smoothing materials - JR diamond tools Co.,Ltd - China - September 17, 2019 - 80.00 Dollar US$

Resin Bond Diamond WheelsGrinding and polishing and smoothing materials - JR diamond tools Co.,Ltd - China - September 17, 2019 - 80.00 Dollar US$Resin Bond Diamond Wheels of all types, sizes, shapes and abrasives. Standard grinding wheels can ship from stock. Custom Resin Bond Diamond Wheels and abrasive products can be manufactured promptly. Diamond grinding wheels are designed for wet or dr...

-

Ceramic Bond Diamond Grinding WheelGrinding and polishing and smoothing materials - JR diamond tools Co.,Ltd - China - September 17, 2019 - 80.00 Dollar US$

Ceramic Bond Diamond Grinding WheelGrinding and polishing and smoothing materials - JR diamond tools Co.,Ltd - China - September 17, 2019 - 80.00 Dollar US$Ceramic Bond Diamond Grinding Wheel Surface Grinding Wheel Vitrified Grinding Wheel Most commonly employed in the grinding of PCD and PCBN tools. Coastal Diamond vitrified grinding wheels have enabled polycrystalline tool fabricators to obtain excell...

Safe Trade Tips

- Ask for business references and check them

- Use a payment method that offers better protection for all such as Letters of credit and verified professional escrow services. Avoid payments in advance such as money transfers

- Verify their business via their local Chamber of Commerce

- Search the internet using their website address, their business name, their phone and fax numbers, and their email addresses to see if you can find any feedback about them.

- Get to know more about scams and fraud to avoid: Internet Crime Complaint Center - Consumer Financial Protection Bureau

- This site is never involved in any transaction, and does not handle payments, shipping, guarantee transactions, provide escrow services, or offer "buyer protection" or "seller certification"