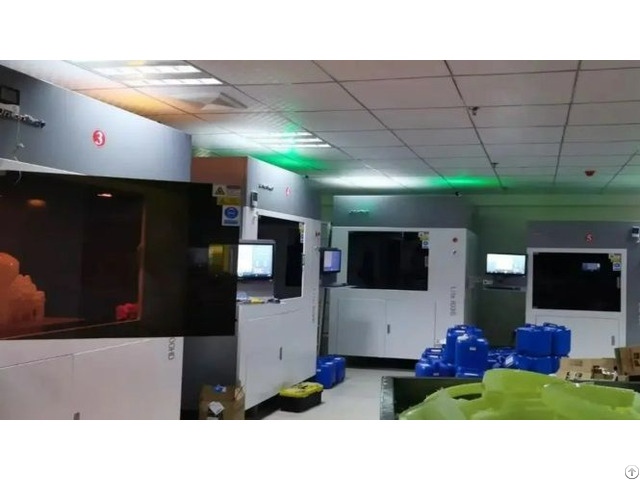

Urethane Casting - China

price: contact company for price

What is Urethane casting? Urethane casting is a manufacturing process similar to injection molding where urethane resin is cast in a cavity between two silicone mold halves.

The process replicates a master model by pouring a silicone mold around it.

In a highly skilled procedure, the mold is sliced into two halves, the master model is removed, and then a gating and ventilation system is added.

Subsequently, the model maker casts a urethane-based resin into the resulting cavity and cures it under a vacuum to prevent air bubble intrusion.

Vacuum casting is better known as urethane casting or polyurethane casting in the US.

Vacuum Casting Process

Step 1: Master Building Masters represent 3D solids derived from your CAD designs.

Typically crafted via CNC machining or 3D printing, they are meticulously fabricated under controlled conditions, often at 40°C.

Once the masters are meticulously finished and thoroughly inspected, the next phase involves progressing to silicone mold creation.

Step 2: Mold Making The creation of casting molds commences with liquid silicone.

The casting box is partially filled with this liquid silicone, and then subjected to controlled heating until the silicone is fully cured.

Following this, the mold undergoes a 16-hour curing process within an oven.

Additional batches of heated silicone are poured to complete the mold, ensuring comprehensive coverage.

Once fully dried, the mold is carefully cut open to extract the master component.

Step 3: Part Production Production of parts begins by pouring casting resins into the emptied mold cavity.

This process results in the creation of highly precise replicas of the original master.

The flexibility extends to the possibility of overmolding with multiple materials.

Typically, silicone molds maintain their effectiveness for approximately 20 reproductions of the initial pattern.

This structured approach ensures the replication of intricate designs with fidelity and efficiency, leveraging the precision of CAD designs and the versatility of silicone molding techniques.

Company Contact:

- Posted By: Thingyfy Technology Co.Ltd.

- Phone: 13500242999

- Address: No. 1, Zhufeng Avenue West, Doumen District, Zhuhai , Guangdong , China

- Email:

- Website: https://www.thingyfymfg.com/

Published date: December 6, 2024

- Business Description: But beyond our technical prowess, Thingyfy was also a brand with a soul.

We believed in using their platform for good, striving to make a positive impact on the world around us.

From environmentally friendly manufacturing practices to community outreach programs, Thingyfy was more than just a company – it was a force for good in a rapidly changing world.

And so, the story of Thingyfy serves as a testament to the power of passion, innovation, and the belief that with a little bit of imagination, anything is possible.

In a world filled with endless possibilities, Thingyfy wants to stand as a shining example of what can be achieved when you dare to dream.

Our Products:

- Thingyfy 3d Printing Services

- Thingyfy Cnc Turning

- Urethane Casting

- Thingyfy Sheet Metal

- Thingyfy Aluminum Extrusion

Related listings

-

A High Pressure Control ValveMachined castings - Zhejiang SUPCON Fluid Technology Co., Ltd. - China - March 6, 2024 - 1.00 Dollar US$

A High Pressure Control ValveMachined castings - Zhejiang SUPCON Fluid Technology Co., Ltd. - China - March 6, 2024 - 1.00 Dollar US$Performance advantages Adopting modular design concept, combining the American and Japanese schools of high-precision control and the German school of modular concept. The inner cavity of the valve body is S-shaped distribution, smooth and without de...

-

Iz Metal Grill And FireboxMachined castings - Prizmasteel - Turkey - December 10, 2023 - 40.00 Dollar US$

Iz Metal Grill And FireboxMachined castings - Prizmasteel - Turkey - December 10, 2023 - 40.00 Dollar US$Fast production thanks to laser cutting machines, thanks to the precision cutting quality, carries the manufacturing process to the fastest point in industrial production. Material : 1.5 mm Dkp Stell Dimensions : 35 cm x 35 cm x 35 cm Weight : 6-7 kg...

-

Iz Metal FireboxMachined castings - Prizmasteel - Turkey - December 10, 2023 - 35.00 Dollar US$

Iz Metal FireboxMachined castings - Prizmasteel - Turkey - December 10, 2023 - 35.00 Dollar US$Fast production thanks to laser cutting machines, thanks to the precision cutting quality, carries the manufacturing process to the fastest point in industrial production. IZ Portable Grill and Fire Box Easy to assemble and carry With Special Designe...

Safe Trade Tips

- Ask for business references and check them

- Use a payment method that offers better protection for all such as Letters of credit and verified professional escrow services. Avoid payments in advance such as money transfers

- Verify their business via their local Chamber of Commerce

- Search the internet using their website address, their business name, their phone and fax numbers, and their email addresses to see if you can find any feedback about them.

- Get to know more about scams and fraud to avoid: Internet Crime Complaint Center - Consumer Financial Protection Bureau

- This site is never involved in any transaction, and does not handle payments, shipping, guarantee transactions, provide escrow services, or offer "buyer protection" or "seller certification"