Cassava Flour Production Line - China

price: 352000.00 Dollar US$

Cassava flour production line Our company devloped edible cassava flour production line which aim at africa local abundent cassava source.

The newest food grade cassava flour production process solve daily staple food and develop cassava usage and processing.

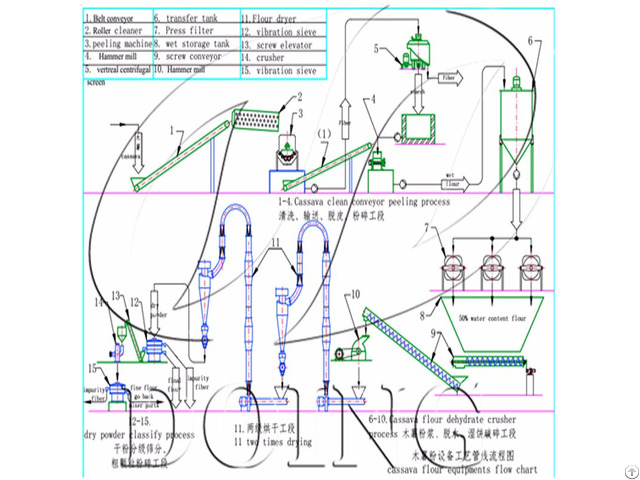

Process description of cassava flour production line

Root reception and washing Roots are dropped onto the belt of an inclined belt conveyor where stems and branches are picked out and woody tissues of cassava roots are manually cut off.

Prevent hard woody tissues entering into next rasping unit and reduce the rasper loading.

On the other end of belt is a squirrel cage type dry cleaner which will get rid of the sand and peels without water.

The sand and peels pass through the meshes of dry cleaner and then are collected to a sand collecting gutter for periodical clean-up.

Dry cleaned the roots are sent to paddle washer for 3 stage water cleaning to get rid of remained sands and broken skin.

Add process waste water in the first stage washer.

Sands will be soaked in water and removed.

The roots pass through the trough in different area to next stage with cleaning water, cleaning washing water enter into next washer.

The cassava is cleaned by this countercurrent method.

Washed clean roots are placed onto inspection belt of the inclined belt conveyor.

Grinded and rasping unit

The tuber is grinded and become low broken percentage .

That means 50% cassava flour is not separated and combined with fiber.

In the rasping process, should add process water to dilute slurry.

the potato slurry in the collection trough is pumped in to desanding cyclone.

Don't make the cassava flour dissociate and make the cassava flour combine with fiber.

So the special design of rasper is vital for flour fineness and freeness.

Desanding unit

In the desanding unit, sands and sawteeth etc coarse particle will be removed from cassava slurry.

This unit is made of ceramic cyclongnetts, sands collection tank, automatic desanding valve and back flush device.

back flush avoid cassava flour loss in desanding process.

Desanded slurry is sent to dewatering unit.

Cassava flour detoxification and dewatering

Because there is hydrocyanic acid toxic substance in cassava peels.

In this unit, we use filter presser to dewatering and detoxification process.

When slurry reaches to certain liquid position in slurry tank, start to dewater by frame filter presser.

Then transport the material to cassava flour drying procedure by belt conveyor.

Drying and packing unit

Dewatered cassava flour cake contains high moisture to 45~50%, which can’t enter into flash dryer directly and will be mixed with dry flour and reduce the moisture to 38%, then transported to feeding port of flash dryer by conveyer belt, pass through feeder and enter into raiser.

The heat source of flash dryer is steam heat exchanger.

Wet cassava flour is heated by hot wind and water is steamed.

After drying, cassava flour and air are separated in cyclone separator.

At the bottom of cyclone separator, it is closed by air closer.

after wet air leave cyclone separator, which is discharged in to atmosphere.

Collected cassava flour is transported to vibration sieve unit; the coarse particulate matter is sieved out.

The sieved cassava flour is transported to hopper for storing and cooling.

Company Contact:

- Posted By: Jiaozuo Doing Machanical Equipment Co., Ltd

- Phone: 0086 135 2661 5783

- Address: www.cassavaprocessingmach ine.com Zhengzhou,Henan,China, zhengzhou , Henan province, China

- Email:

Published date: December 21, 2017

- Business Description: Spontaneous research and development the following product:

cassava machine, cassava starch machine, cassva processing machine, cassava starch processing machine, gluten syrup machine from statch

Potato, sweet potato and cassava starch production plant

Glucose syrup & Maltose syrup processing plant

Corn syrup & high fructose processing plant

Air flow clash dyer

Drum rotary dehydration machine .

Related listings

-

Broken Rice Glucose Syrup Processing MachineMachinings - Jiaozuo Doing Machanical Equipment Co., Ltd - China - December 11, 2017 - 1652000.00 Dollar US$

Broken Rice Glucose Syrup Processing MachineMachinings - Jiaozuo Doing Machanical Equipment Co., Ltd - China - December 11, 2017 - 1652000.00 Dollar US$Broken rice glucose syrup processing machine Description of rice glucose syrup processing machine (1) Starch milk adjustment: Raw broken rice is unloaded to rice tank. With water’s adding, it is sent to steeping tanks for softening. Dipped rice is pu...

-

Glucose Syrup Production Line MachineMachinings - Jiaozuo Doing Machanical Equipment Co., Ltd - China - December 11, 2017 - 1356000.00 Dollar US$

Glucose Syrup Production Line MachineMachinings - Jiaozuo Doing Machanical Equipment Co., Ltd - China - December 11, 2017 - 1356000.00 Dollar US$Glucose Syrup Production Line/Equipment/Plant The advantages of glucose syrup production line 1. Advanced and reliable glucose processing technology. 2. Energy-saving, water-saving, labor-saving and little pollution. hot recycling close type producti...

-

Potato Starch Producing Chart FlowMachinings - Jiaozuo Doing Machanical Equipment Co., Ltd - China - December 11, 2017 - 253200.00 Dollar US$

Potato Starch Producing Chart FlowMachinings - Jiaozuo Doing Machanical Equipment Co., Ltd - China - December 11, 2017 - 253200.00 Dollar US$Potato starch production plant Washing &Crushing Section potato, the material is sent to cage washer through scrape board to get the result of decontamination, cleaning and peeling . Then through a paddle-washing slot, material is sent to crash s...

Safe Trade Tips

- Ask for business references and check them

- Use a payment method that offers better protection for all such as Letters of credit and verified professional escrow services. Avoid payments in advance such as money transfers

- Verify their business via their local Chamber of Commerce

- Search the internet using their website address, their business name, their phone and fax numbers, and their email addresses to see if you can find any feedback about them.

- Get to know more about scams and fraud to avoid: Internet Crime Complaint Center - Consumer Financial Protection Bureau

- This site is never involved in any transaction, and does not handle payments, shipping, guarantee transactions, provide escrow services, or offer "buyer protection" or "seller certification"