Cnc Lathe Back Feeding For Shaft Parts - China

price: 10000.00 Dollar US$

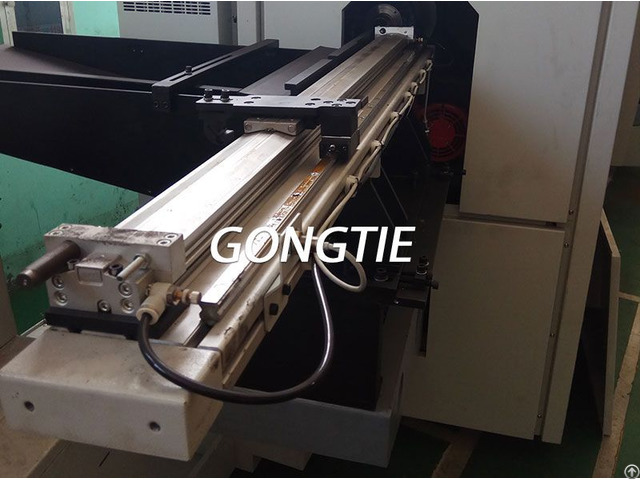

CNC lathe Back Feeding for Shaft Parts

CNC lathe with axial division, CNC lathe with feeding device supplier

Q series-precise linear guide-way with flat bed in blade row : Q5, Q7, Q5C, Q7C

Q5, Q7, with the features of high precision.

high speed.

high efficiency, is the ideal selection for substituting hard rail lathes and imported lathes.

* High precision : importing components from Japan and Taiwan through the advanced assembly and inspection technology, realizing the precise turning with tolerance of μ level.

* High speed : more than 5000RPM for spindle, rapid traverse 20m/s, to reach the high speed machining.

*High-efficiency : with the concept of technique innovation and application oriented, and sustainability improve the overall performance, to make the processing more efficiency.

* Stability : high quality requirement and strict selecting for all the components, to make the machine performance more stable.

Q5C, Q7C, (Synchronous electric spindle)- the best selection for substituting the imported lathes.

* More precision: the complete Synchronous servo configuration for the spindle and the X/Z axis, makes the processing accuracy get a new break through.

* Higher speed: the superior Synchronous electric spindle make the spindle perform higher, faster, and more stable.

* More efficiency: the complete, Synchronous control for the core parts (all the axis), makes the processing efficiency better.

In this technical solution, we use customized back feeding device to combine the precise Q series CNC lathe to realize the processing of relatively long shafts or such kind of work pieces.

Main parameters UNIT Q5 Q7 Q5C Q7C

Capability Max.

swing

diameter mm 400/98 400/98 400/98 400/98 Max.

turning

length mm 200 300 200 300 Max.

bar

through-hole mm 20(25) 26(35) 20(25) 26(35)

Axis

Stroke X-axistravel mm 280 320 280 320 Z-axistravel mm 240 315 240 315

Rapid

Traverse X/Z-axis m/min 20 20 20 20

Spindle Spindle

nose size N/A A2-4 A2-5 A2-4 A2-5 Spindlethrough holediameter mm 35(37) 48 35(37) 48 Spindle servo motor power kW (asynchronous) 2.2/3.7 (asynchronous) 3.7/5.5 synchronous electric spindle synchronous electric spindle Spindle speed range rpm 0~5000 0~5000 0~6000 0~6000 Work piece clamping method N/A homemade collet homemade collet homemade collet homemade collet

Tool

holder Numberoftools PCS 5 5 5 5 Toolholder

type N/A Dovetail row of knives Dovetail row of knives Dovetail row of knives Dovetail row of knives OPT T-slot blade row+live tool T-slot blade row+live tool T-slot blade row+live tool T-slot blade row+live tool Toolholder

center height

in radial mm 50 50 50 50 Tool size mm 16*16 16*16 16*16 16*16 Boring rod diameter mm 25 25 25 25

Accuracy X\Z axis repeating postioning accuracy mm 0.002 0.002 0.002 0.002

Others Cooling motor

capacity L 120 120 120 120 hydraulic box

capacity L 60 60 60 60 Required electric power kVA 7 8 7 8 Height from floor to

spindle center mm ≈1070 ≈1070 ≈1070 ≈1070 Overall size

(L*W*H) mm 1500*1250*1650 1650*1300*1650 1500*1250*1650 1650*1300*1650 Net weight kg ≈1200 ≈1700 ≈1200 ≈1700

Standard tool box, instruction, manual, cooling system, lighting system, lubricating system

Optional collet, chuck, foot switch, programmable blowing function, precision c, axial division, living tool, auto door, loading & unloading system, industrial robot, auto bar feeder, parts catching device, chip conveyor, auto detecting system, auto

tool compensation system, high pressure cooling system CONFIGURATION More Product Please View Hifactory.

Company Contact:

- Posted By: Ningbo Gongtie Smart Technology Co., Ltd.

- Phone: +8657488184686

- Address: No.16,Gaoya Road,Jiangshang town, Ningbo , Zhejiang , China

- Email:

- Website: https://www.cnc-gongtie.com

Published date: August 2, 2019

- Business Description: Ningbo Gongtie Smart Technology Co., Ltd. is national high-tech enterprise, which focusing on precise CNC lathe , whole machine automation ,"machine substitution" project innovation and smart factory integration.

The company headquarter is based on Ningbo of China, and the European R&D center is located in Reggio emilia, ITALY .

Since the foundation in 2008, the company continuously advocates scientific and technical innovation .

For better servicing the customers, Gongtie fully take the advantages of advanced concept and technology from European country like ITALY and GERMANY, connect with the domestic actual manufacturing, and dedicate to the precise CNC lathes and industrial robot field, set up the most feasible custom-made technique solution and "EPC" project for the final customers.

Please visit our website: https: //www.

cnc-gongtie.

com/

Related listings

-

Cnc Lathe With Bar FeederMachinings - Ningbo Gongtie Smart Technology Co., Ltd. - China - August 2, 2019 - 10000.00 Dollar US$

Cnc Lathe With Bar FeederMachinings - Ningbo Gongtie Smart Technology Co., Ltd. - China - August 2, 2019 - 10000.00 Dollar US$CNC lathe with bar feeder CNC lathe with simple feeding system, cnc lathe with automatic bar feeder High precision CNC lathe with flat bed, the appearance design is fashion, simple and practical, the most wonderful configuration is with a bar feeder,...

-

Slant Bed Lathe With Programmable BlowingMachinings - Ningbo Gongtie Smart Technology Co., Ltd. - China - August 2, 2019 - 10000.00 Dollar US$

Slant Bed Lathe With Programmable BlowingMachinings - Ningbo Gongtie Smart Technology Co., Ltd. - China - August 2, 2019 - 10000.00 Dollar US$slant bed lathe with programmable blowing OEM slant bed lathe, cnc lathe with Slant Bed price S series-precise linear guide-way with flat bed in blade row : S36, S350 with the features of high precision. high speed. high efficiency, is the ideal sele...

-

Cnc Lathe With Slant BedMachinings - Ningbo Gongtie Smart Technology Co., Ltd. - China - August 2, 2019 - 10000.00 Dollar US$

Cnc Lathe With Slant BedMachinings - Ningbo Gongtie Smart Technology Co., Ltd. - China - August 2, 2019 - 10000.00 Dollar US$cnc lathe with Slant Bed slant bed lathe with programmable blowing OEM slant bed lathe S400, S500, high precision, stability, high efficiency, is a high cost-Competitive CNC lathe for realizing the precision machining. *High precision: importing comp...

Safe Trade Tips

- Ask for business references and check them

- Use a payment method that offers better protection for all such as Letters of credit and verified professional escrow services. Avoid payments in advance such as money transfers

- Verify their business via their local Chamber of Commerce

- Search the internet using their website address, their business name, their phone and fax numbers, and their email addresses to see if you can find any feedback about them.

- Get to know more about scams and fraud to avoid: Internet Crime Complaint Center - Consumer Financial Protection Bureau

- This site is never involved in any transaction, and does not handle payments, shipping, guarantee transactions, provide escrow services, or offer "buyer protection" or "seller certification"