Potato Starch Production Plant - China

price: 1562000.00 Dollar US$

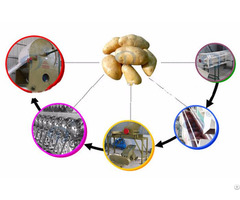

Process description 1Potato receiving, transporting and cleaning unit

Store the potato in storage pool.

Then the de-stone machine will remove the dirt and other foreign matters completely.

Finally, store the clean potato in a temporary storage hopper.

2 Potato rasping unit

The rasping unit is the most important part of Potato starch extraction.

Rasping mill with high efficiency allows the starch granules in the potato cells to be released out completely, which ensures minimum quantity of the remaining starch in the potato residue.

The rasping potato slurry is pumped into de-sanding unit by a fiber pump.

3 De-sanding unit

Rasping potato slurry is pumped through the fiber pump into the de-sanding cyclone.

When the slurry enters de-sanding cyclone, the light phase of starch and potato residue come out of the top as overflow, and the heavy phase like sands will be discharged from the bottom.

4 Starch extracting unit

Centrifugal extraction is another key unit which influences the potato starch yields.

The potato slurry enters the first stage centrifugal sieve from de-sanding cyclone, the slurry is separated into starch slurry and potato residue under the centrifugal force.

Starch slurry is pumped through the de-foaming pump to the hydro-cyclone station for washing starch, and the potato residue is sent to second and third grade centrifugal sieves through fiber pump for starch recovery.

5 Potato residue dewatering

We use a centrifugal sieve for potato residue dewatering, it works like the extraction sieve.

Finally, potato residue is transported out of the workshop, the extracted water return to the process water system.

6 Starch washing and concentration unit

The 16 grade hydro-cyclone station guarantees the quality of the starch completely, which is the most important unit of the entire production line.

The starch slurry enters the third stage of the hydro-cyclone for concentration, and the fresh water enters the hydro-cyclone from the other end which washes starch.

The overflow enters two grade recovery station to recycle starch, the bottom flow is washed through 13 grade washing cyclone to ensure that the starch slurry does not contain impurities and final starch will be in accordance with national standard.

7 Starch dewatering unit

The starch out of the cyclone station has big moisture so it must be dewatered then dried.

The starch slurry enters vacuum dewatering filter tank from the starch milk buffer tank.

Under the vacuum formed by the vacuum pump, the starch slurry is sucked to the drum surface, then filtrate goes through filter mesh and enters the filtrate separating tank.

The starch cake remains on mesh surface and is scraped off by a scraper and transported by the conveyor belt into the air dryer.

Then weighing and packing.

Company Contact:

- Posted By: Jiaozuo Doing Machanical Equipment Co., Ltd

- Phone: 0086 135 2661 5783

- Address: www.cassavaprocessingmach ine.com Zhengzhou,Henan,China, zhengzhou , Henan province, China

- Email:

Published date: December 1, 2017

- Business Description: Spontaneous research and development the following product:

cassava machine, cassava starch machine, cassva processing machine, cassava starch processing machine, gluten syrup machine from statch

Potato, sweet potato and cassava starch production plant

Glucose syrup & Maltose syrup processing plant

Corn syrup & high fructose processing plant

Air flow clash dyer

Drum rotary dehydration machine .

Related listings

-

Potato Starch Manufacturing PlantMachinings - Jiaozuo Doing Machanical Equipment Co., Ltd - China - November 26, 2017 - 135600.00 Dollar US$

Potato Starch Manufacturing PlantMachinings - Jiaozuo Doing Machanical Equipment Co., Ltd - China - November 26, 2017 - 135600.00 Dollar US$Process description of potato starch manufacturing plant and the main steps of potato starch processing machine. 1Potato receiving, transporting and cleaning unit Store the potato in storage pool. Then the de-stone machine will remove the dirt and ot...

-

Starch Glucose Syrup Production LineMachinings - Jiaozuo Doing Machanical Equipment Co., Ltd - China - November 26, 2017 - 650000.00 Dollar US$

Starch Glucose Syrup Production LineMachinings - Jiaozuo Doing Machanical Equipment Co., Ltd - China - November 26, 2017 - 650000.00 Dollar US$Starch glucose syrup production line The description of new technology of starch glucose production line: 1. Old technology need to make starch firstly, New technology need to make corn flour or rice flour firstly; 2. Continuous spray liquefaction, m...

-

High Quality Corn Fructose Syrup ProductionMachinings - Jiaozuo Doing Machanical Equipment Co., Ltd - China - November 26, 2017 - 2450000.00 Dollar US$

High Quality Corn Fructose Syrup ProductionMachinings - Jiaozuo Doing Machanical Equipment Co., Ltd - China - November 26, 2017 - 2450000.00 Dollar US$Introduction of high fructose corn syrup production machine High-fructose corn syrup (HFCS) is a product of maize (corn) that has been processed into a syrup with a higher than normal fructose-glucose ratio. Here is the processing line of high frutco...

Safe Trade Tips

- Ask for business references and check them

- Use a payment method that offers better protection for all such as Letters of credit and verified professional escrow services. Avoid payments in advance such as money transfers

- Verify their business via their local Chamber of Commerce

- Search the internet using their website address, their business name, their phone and fax numbers, and their email addresses to see if you can find any feedback about them.

- Get to know more about scams and fraud to avoid: Internet Crime Complaint Center - Consumer Financial Protection Bureau

- This site is never involved in any transaction, and does not handle payments, shipping, guarantee transactions, provide escrow services, or offer "buyer protection" or "seller certification"