Customer Case Study For Wingtat - China

price: contact company for price

Challenges Faced by Zhongqing:

1 - High-Transparency Material Issues:

- Difficulty achieving desired transparency in molded components.

- Instances of fusion lines affecting the surface quality.

2 - Molding Fusion Line Control:

- Fusion lines appearing at convergence points during the injection molding process.

- Adverse effects on product strength and aesthetics.

3 - Large Injection Molding Machine (1200T) Constraints:

- Inability to meet the production demands efficiently.

- Hindered the smooth flow of the manufacturing process.

Wingtat's Comprehensive Solutions:

1 - Mold Design for Transparency and Fusion Lines:

- Employed advanced Moldflow simulations for accurate prediction of fusion line locations.

- Implemented precise timing of sequential hot runners to eliminate transparency and fusion line issues effectively.

2 - Addressing Common Molding Issues:

a.

Insufficient Melt Flow:

- Increased melt temperature to enhance flow characteristics.

- Accelerated injection speed to prevent melt cooling before reaching convergence points.

- Elevated mold temperature to minimize melt temperature reduction.

- Optimized gate design and part thickness to reduce flow resistance.

b.

Air or Volatile Components:

- Integrated venting through parting lines and designed dedicated venting channels.

- Ensured effective removal of air or volatile components during the molding process.

c.

Release Agent Impact:

- Minimized the use of release agents, especially those containing silicon.

- Mitigated potential issues arising from the interaction of release agents with the melt.

d.

Colorant Influence:

- Acknowledged challenges in eliminating fusion lines caused by the addition of colorants.

- Collaborated closely with Zhongqing to optimize colorant choices for improved results.

3 - Mold Defects and Structural Modifications:

- Implemented structural modifications to address persistent fusion line issues.

- Adjusted gate placement to minimize the visibility of fusion lines.

- Balanced system parameters to ensure consistent and optimal results.

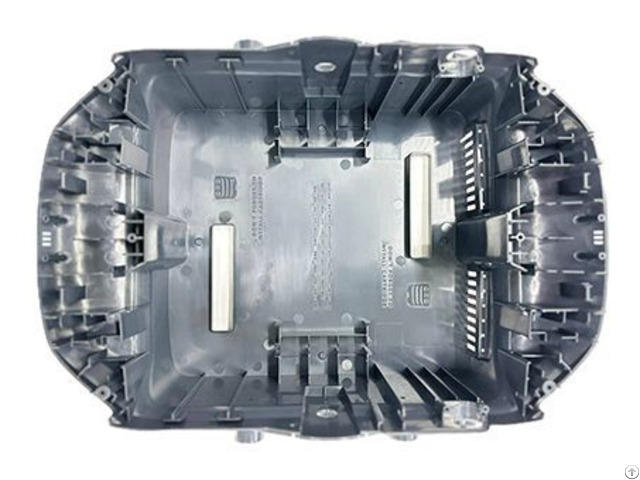

Project Details:

- Client: Beijing Zhongqing Technology Co., Ltd.

- Product Specifications:

- Dimensions: 460X680X178

- Material: ASA-PW978 B

- Mold Cavities: 1*1

- Cycle Time: 120 seconds

- Design Period: 8 working days

- Manufacturing Period: 45 working days

- Manufacturing Date: February 2023 Outcomes:

Wingtat's meticulous approach to mold design, process optimization, and structural modifications successfully addressed Zhongqing's challenges.

The collaboration resulted in improved transparency, resolved fusion line issues, and enhanced production capabilities, leading to a high level of client satisfaction and confidence in ongoing partnerships.

Company Contact:

- Posted By: Wing Tat Industrial (HK) Co., Ltd

- Phone: 852-24670218

- Address: No. 3, Lindong 3rd Road, Lincun, Tangxia Town, Dongguan , Guangdong , China

- Email:

Published date: June 25, 2024

- Business Description: Wingtat Plastic Hardware (Hong Kong) Co., Ltd. was established in 1988 - It is an injection mold manufacturer specializing in the design and manufacture of high-quality plastic products.

Our company is located in Dongguan City, about 45 kilometers away from Shenzhen.

The factory covers an area of more than 15000m2 and has more than 200 employees, including experienced engineers and technical consultants to provide overall solutions for OEM/ODM projects, as well as well-trained workers and inspectors to produce process products.

Our Products:

- Customer Case Study For Wingtat

- Medical Device Parts Molding Manufacturing

- Rapid Tooling For Injection Molding

- Uwatec Warpage Control Challenges And Wingtat S Solutions

Related listings

-

Songshun Manufacturing Provided Skd10 Mold SteelMoldings - Dongguan Songshun Mould Steel Co., Ltd. - China - May 6, 2024 - check with company for price

Songshun Manufacturing Provided Skd10 Mold SteelMoldings - Dongguan Songshun Mould Steel Co., Ltd. - China - May 6, 2024 - check with company for pricewith the continuous development of manufacturing industry, the performance requirements of mold steel are getting higher and higher. as a high-quality mold steel, skd10 mold steel has been widely used in the field of mold manufacturing due to its exc...

-

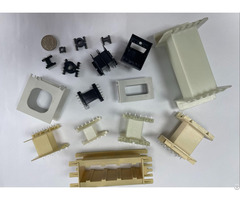

Transformer Bobbins And Custom MoldingsMoldings - CB Magnetics Co.,Limited - China - April 25, 2024 - contact company for price

Transformer Bobbins And Custom MoldingsMoldings - CB Magnetics Co.,Limited - China - April 25, 2024 - contact company for priceSince 2009, we have averagely produced 30 custom molding tools each month. Our professional experience and experts make us skilled at the designing and manufacturing of precision engineered thermoplastic and thermoset parts. We have technologically a...

-

Graphite BoxMoldings - Henan Unitfine Graphite Products Co., Ltd. - China - December 26, 2023 - 10.00 Dollar US$

Graphite BoxMoldings - Henan Unitfine Graphite Products Co., Ltd. - China - December 26, 2023 - 10.00 Dollar US$The Graphite Box is a versatile and innovative product widely employed in various fields, offering users convenient and efficient solutions. Below is an introduction to the applications of the Graphite Box in different domains: Metal Melting: Crafted...

Safe Trade Tips

- Ask for business references and check them

- Use a payment method that offers better protection for all such as Letters of credit and verified professional escrow services. Avoid payments in advance such as money transfers

- Verify their business via their local Chamber of Commerce

- Search the internet using their website address, their business name, their phone and fax numbers, and their email addresses to see if you can find any feedback about them.

- Get to know more about scams and fraud to avoid: Internet Crime Complaint Center - Consumer Financial Protection Bureau

- This site is never involved in any transaction, and does not handle payments, shipping, guarantee transactions, provide escrow services, or offer "buyer protection" or "seller certification"