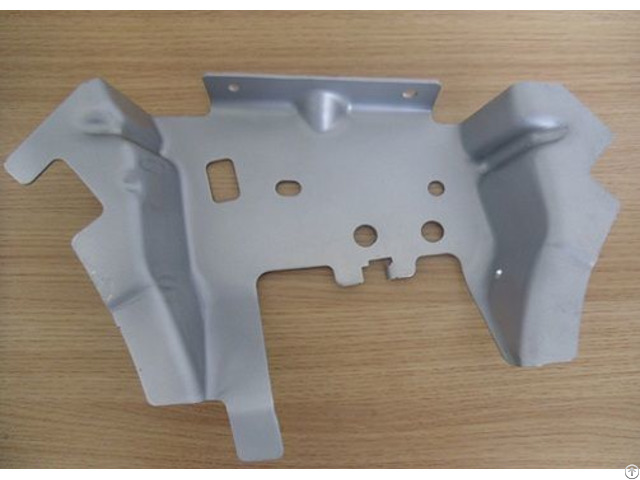

Steel Stampings - China

price: 1.00 Dollar US$

custom metal stampings, steel stampings, sheet metal parts

Cooperation model: OEM or ODM

As per customer specific requirements

or customer give us the specified sample;

or the customer conceptual or preliminary design;

or the customer sketched idea.

Accept drawing format: .

pdf /.

jpg / .

dwg / .

igs / .

stp etc.

Material: Sheet stock is of many materials, including carbon steel, alloy steel, stainless steel, aluminum, brass even plastics.

Material condition: On flat sheet, plate coil supplying condition

Hot rolled or cold rolled or cold drawn for options.

Material thickness: From 0.2mm~6mm

Application material standard:

If there is no any specially requirement, we often sugguest our customer to try the equivalent China National (GB) standard material that our engineering team proposes which to be properly converted from ANSI, ASTM, SAE, EN, DIN, BS, JIS, and etc., to contribute the material cost control.

If it is necessary to use exact designated material no., it is also possible choice.

Available processing (Technique):

Shearing - Crimping - Laser cutting - Bending -Stamping - Pressing - Deep drawing - Rolling -Forming - Fabricating - Drilling - Tapping - Riveting - Spot welding - TIG - Assembling

Precision: Average level: ±0.05mm, depending the part size and thickness and material

Company Contact:

- Posted By: Shijiazhuang Youzheng Machinery Co., Ltd

- Phone: 86 311 80663708

- Address: 1-1-2212, Huijing International Building, No 265 Zhongshan East Road, Shijiazhuang, China., Shijiazhuang , Hebei , China

- Email:

- Website: http://www.youzhengmetal.com/

Published date: February 22, 2017

- Business Description: As one of the largest and most diverse metal fabricators in the North of China, Shijiazhuang Youzheng Machinery starts as a metal fabricator and completes projects with sheet metal fabrication, tube fabrication, wire forming and fabrication, welding, powder coating, assembly, packing and fulfillment.

We have a large, experienced workforce, multiple shift operation and computer automation to increase efficiency and quality.

We are able to handle short or long run production runs and rely on the principle that total customer satisfaction should be our highest priority.

We now have 6 metal fabricating facilities.

We have added engineering staff for quoting and job processing.

Our growth has been in all aspects of sheet metal punching, laser cutting, forming, bending, rolling, welding, tube bending, wire forming, casting, machining, and powder coating.

We have grown from China customers to customers in USA, Canada, France, Australia, United Kingdom, Germany, Spain, Sweden, Netherlands, Belgium, Poland etc.

As the China precision metal fabricator, we are always looking for continuous improvement in metal fabrication equipment and in employees with skill sets that match or add to our core values.

ADVANTAGES:

PR OBLEM RESOLUTION

We understand that problems and issues will happen from time to time.

At Youzheng Machinery, you will deal directly with your account manager who will help in resolving any issue.

You have one point of contact and will never have to worry about anyone "passing the buck".

We want every experience with us to be a positive one.

So when there is a problem, your account manager will ensure it is immediately resolved directly through them so you can get back to feeling great about partnering with Youzheng Machinery.

QUALITY PARTS

When you purchase from Youzheng Machinery you are purchasing directly from us.

Our factories work directly with our certified engineers and quality control personnel to ensure that your parts meet the exact specifications of your prints and instructions.

Our policy is to check every shipment of parts, prior to delivery to your company, to ensure it meets our rigorous quality control checks.

We are committed to providing you a quality product time and time again.

Sheet metal fabrication

Over the last 10 years, Shijiazhuang Youzheng Machinery has built a reputation as an essential partner to companies worldwide through the specialized services we offer our clients.

Related listings

-

Bldc Motor Stator Rotor Core Stamping And LaminationMoldings - Shenzhen Jiaye Industrial Equipment co., ltd. - China - December 4, 2016 - 10.00 Dollar US$

Bldc Motor Stator Rotor Core Stamping And LaminationMoldings - Shenzhen Jiaye Industrial Equipment co., ltd. - China - December 4, 2016 - 10.00 Dollar US$Our service: 1. Motor stator and rotor core lamination 2. Motor stator customization with 3. Stator Punching and stamping mold design & manufacturing 4. Stator Prototype sample customization with wire cutting and laser welding. 5. Stator epoxy co...

-

Liquid Silicone Rubber Injection MoldingMoldings - Xiamen Better Silicone Co.,Ltd - China - November 23, 2016 - 8500.00 Dollar US$

Liquid Silicone Rubber Injection MoldingMoldings - Xiamen Better Silicone Co.,Ltd - China - November 23, 2016 - 8500.00 Dollar US$Liquid Silicone Rubber Molding Liquid Silicone Rubber Molding is also called Liquid Silicon Rubber Injection Mold & LIM, which is used to produce liquid silicone rubber products by injection machines, not traditional silicone rubber compression m...

-

Plastic Injection Mould For Meter CaseMoldings - EX Plastic Injection Mould Co.,Ltd. - China - November 14, 2016 - contact company for price

Plastic Injection Mould For Meter CaseMoldings - EX Plastic Injection Mould Co.,Ltd. - China - November 14, 2016 - contact company for priceChina Plastic Meter Case Injection Mould Manufacturer: Plastic Meter Case Mould made of stainless steel, DME mold base, Muti Cavity, Polished Surface. Mould Service: 50, 000, 000 shots. Mould Materials: Stainless Steel. Product Material: ABS, PC, PBT...

Safe Trade Tips

- Ask for business references and check them

- Use a payment method that offers better protection for all such as Letters of credit and verified professional escrow services. Avoid payments in advance such as money transfers

- Verify their business via their local Chamber of Commerce

- Search the internet using their website address, their business name, their phone and fax numbers, and their email addresses to see if you can find any feedback about them.

- Get to know more about scams and fraud to avoid: Internet Crime Complaint Center - Consumer Financial Protection Bureau

- This site is never involved in any transaction, and does not handle payments, shipping, guarantee transactions, provide escrow services, or offer "buyer protection" or "seller certification"