Gi Steel Tile Roll Forming Machine 75mm Shaft Diameter Custom Design - China

price: check with company for price

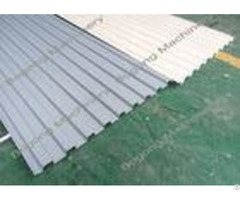

Steel Roof Tile Roll Forming Machine / GI Steel Tile Roof Forming Machine Description Steel metal tile roof is roll formed by Steel Roof Tile Roll Forming Machine / GI Steel Tile Roof Forming Machine, this is the special steel roof with steps, same as no step colorroof, it is also layout on steel construction as roof, it can keep building lookbeautiful andbe more long time using life.

Xiamen Bogong Machinery brandSteel Roof Tile Roll Forming Machine / GI Steel Tile Roof Forming Machine produce very economy material for steel sturcture house, so the big advantage of steel structure house is economy.

The metal step tile roof is matched with heavy structure, we called steel C purlin or steel Z purlin.

We Bogong Machinery also manufactureinterchangeabl eC & Z purlineroll forming machine, standing seam roof roll forming machine, steel gutter roll forming machine and ridge cap roll forming machine.

Welcome to contact with us for other steel profile roll forming machine.

Technical Parameter - - - -

Parameters | Specification | Voltage | 380V/50HZ/3PH | Driving Motor | 5.5KW | Hydraulic Press/Cuting Motor | 5.5KW | Forming Steps | 16 | Working Speed | 2-4m/min | Roofing Height | 29mm | Effective Width | 970mm | Material Width | 1220mm | Thickness for Steel | 0.3-0.7mm | Shaft Diameter | 75mm | Shaft Material | High grade 45# forged steel | Roller Material | 45# steel with polished and heat treatment | PLC Cabinet | Schneider, Mitsubishi or Delta | Encoder | Omron | Sprocket Wheel | 45 steel high-frequencies quench | Cutting Blade Material | Cr12 steel | Machine Frame Material | Fine welded structural steel; | Roofing Material | PPGI, GI steel G245-345 | Painted Color | Blue+Gray White Or Customization | Overall Size | 9000*1600*1600mm | Weight | 6000KGS | - - - - Roof Tile Design drawing This Steel Roof Tile Roll Forming Machine / GI Steel Tile Roof Forming Machine raw material is 1220mm, effective width is about 960mm, roll forming common roof shape at first, then forming steps by step mould and press by hydraulic action driving.

The step tile length can be set according to user's requirements on touch screen.

Shining Roll Forming Rollers and Shafts

Company Contact:

- Posted By: Xiamen Bogong I & E Co., Ltd.

- Phone: 86-592-6382566

- Address: Area 5, No. 788 Jimei North Road, Jimei District, Xiamen, China, Xiamen , fujian , China

- Email:

Published date: April 25, 2018

- Business Description: With good faith in roll forming machines industrial, Xiamen Bogong Automatic Technology Co.

Ltd has been on effort for kinds of roll forming machines more than 10 years.

During this period, except ourselve roll forming machines, many oversea customers need other assistant help such steel coil.

Related listings

-

Guide Rails Shutter Door Roll Forming Machine For Light Steel ConstructionRope and chain and cable and wire and strap - Xiamen Bogong I & E Co., Ltd. - China - April 25, 2018 - check with company for price

Guide Rails Shutter Door Roll Forming Machine For Light Steel ConstructionRope and chain and cable and wire and strap - Xiamen Bogong I & E Co., Ltd. - China - April 25, 2018 - check with company for priceSilencer Cotton Shutter Door Guider Guide Rails Roll Forming Machine Steel Rollers Main Features Metal Rollers Silencer Shutter Door Guide Rails Roll Forming Machine YX55-42 choose roll forming method, forming part ofshutter door guider shape at firs...

-

Custom Steel Sheet Roller Shutter Door Roll Forming Machine 75mm Shaft DiameterRope and chain and cable and wire and strap - Xiamen Bogong I & E Co., Ltd. - China - April 25, 2018 - check with company for price

Custom Steel Sheet Roller Shutter Door Roll Forming Machine 75mm Shaft DiameterRope and chain and cable and wire and strap - Xiamen Bogong I & E Co., Ltd. - China - April 25, 2018 - check with company for priceCustom Steel Sheet Roller Shutter Door Panel Roll Forming Machine Introduction Of Rolling Shutter Door Machine This Custom Steel Sheet Roller Shutter Door Panel Roll Forming Machine has been designed for producing the corrugation sheet panels which a...

-

Galvanized Coil Floor Deck Roll Forming Machine Plc Control With EmbossingRope and chain and cable and wire and strap - Xiamen Bogong I & E Co., Ltd. - China - April 25, 2018 - check with company for price

Galvanized Coil Floor Deck Roll Forming Machine Plc Control With EmbossingRope and chain and cable and wire and strap - Xiamen Bogong I & E Co., Ltd. - China - April 25, 2018 - check with company for priceGalvanized Coil Floor Decking Roll Forming Machine With Embossing 76-305-915 Product Description - - - - Type | Roll former for decking profile | Thickness | 0.8mm-1.2mm | Feeding Width | 1250mm | Frame Design | Wall-plate-frame-design | Roll Stages ...

Safe Trade Tips

- Ask for business references and check them

- Use a payment method that offers better protection for all such as Letters of credit and verified professional escrow services. Avoid payments in advance such as money transfers

- Verify their business via their local Chamber of Commerce

- Search the internet using their website address, their business name, their phone and fax numbers, and their email addresses to see if you can find any feedback about them.

- Get to know more about scams and fraud to avoid: Internet Crime Complaint Center - Consumer Financial Protection Bureau

- This site is never involved in any transaction, and does not handle payments, shipping, guarantee transactions, provide escrow services, or offer "buyer protection" or "seller certification"