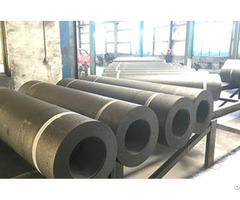

Manufacture Rp Graphite Electrode - China

price: contact company for price

RP Graphite Electrode, Industrial Graphite Electrode, High Density Graphite Electrodes Manufacturer

RP Graphite Electrode

Industrial Graphite Electrode

High Density Graphite Electrodes Manufacturer

Electric resistivity : 7.5-8.6

Bending strength: >=7.5

Elastic Modulus: <=9

Bulk density: 1.54-1.62

Ash: <=0.3

CTE: 2.20-2.60

Regular power graphite electrode is a graphite electrode with allowable current density lower than 17A/cm2 - RP graphite electrode is mainly used in the ordinary power electric furnace for steelmaking, silicon smelting and yellow phosphorus refining etc.

Physical and Chemical Index of Hign Power Graphite Electrode:

Item Unit HP 300~500 550~700

Electric Resistivity Electrode uΩ.

m 5.5~6.8 5.5~7.0 Nipple 4.0~5.5

Bending Strength Electrode MPa ≥10.0 ≥8.5 Nipple ≥18.0

Modulus of Elasticity Electrode GPa ≤13.0 Nipple ≤15.0

Bulk Density Electrode g/cm3 1.62~1.70 Nipple 1.72~1.80

Ash Content Electrode % ≤0.3 Nipple The Coefficient of Thermal Expansion(CTE) Electrode 10-6/℃ 1.80~2.20 Nipple 1.50~1.80 High Power Graphite Electrode Current Carrying Capacity

Norminal Diameter HP Current Carrying Capacity Current Density

inch mm A A/cm2

12 300 13000~17400 17~24

14 350 17400~24000 17~24

16 400 21000~31000 16~24

18 450 25000~40000 15~24

20 500 30000~48000 15~24

22 550 34000~53000 14~22

24 600 38000~58000 13~21

28 700 45000~72000 12~19

32 800 / / Tolerance of Graphite Electrode Diameter and Length(mm)

Nominal Diameter Actural diameter Length

in mm max min Black surface min 12 300 307 302 299 1800/2000

14 350 358 352 349 1800/2000/2200

16 400 409 403 400 1800/2000/2200

18 450 460 454 451 1800/2000/2200

20 500 511 505 502 2000/2200/2400

22 550 562 556 553 2000/2200/2400/2700

24 600 613 607 604 2200/2400/2700/3000

28 700 714 710 707 2200/2400/2700/3000

29 800 816 812 809 2200/2400/2700/3000 Permissible Deviation of Graphite Electrode Length (mm)

Nominal Length Standard Deviation Short Length Deviation max min max min

1800 +100 -100 -100 -275

2000 +100 -100 -100 -275

2200 +100 -100 -100 -275

2400 +100 -100 -100 -275

2700 +200 -150 -150 -275

3000 +200 -150 -150 -300

Company Contact:

- Phone: 5365222183

- Address: Shouguang,Weifang, Shandong, China, weifang , shandong , China

- Email:

- Website: https://www.rongfuindustry.com/

Published date: January 7, 2019

- Business Description: Shandong Rongfu new material technology Co, Ltd., which is located in Shandong province, China, have been specialized in the graphite electrode field for more than 10 years since the year 2007 - Our graphite electrode has been exported to more than 20 countries and areas, including Iran, India, Russia, Germany, Italy, USA, South America, Japan, Korea, Taiwan, Hongkong and so on in the past years.

Our company always serves each customer at credible quality and quality service, and try our best to be most professional graphite electrode supplier in the world.

Graphite electrode is made from top quality low sulphur petroleum coke and high quality needle coke imported from Japan, using high grade coal pitch and other low ash material as adhesion agent.

These raw materials go through the procedure of crushing, calcining, dosing, kneading, forming, multiple roasting, impregnating, graphitizing, mechanical treating, and finally come into graphite electrode.

Graphite electrode is one kind of high temperature and oxidation resistant conductive material.

Graphite electrode has many advantages such as structure uniformity, low ash material, low electric resistivity, low impurity content, low coefficient of thermal expansion, good electrical and thermal conductivity, good oxidation resistance, strong ability of thermal and mechanical vibration resistance, high mechanical strength, high machining accuracy, matching precision of electrode and joint fit.

Graphite electrode is a good conductor of heat and electricity and is widely used in the steelmaking electric arc furnace, refinery furnace, submerged arc furnace and other smelting furnace with high temperature produced by electric arc.

Graphite electrode is excellent material for the production of alloy steel and other metallic non-metallic materials by electric arc furnace.

Graphite electrode is also excellent material for the smelting production of iron alloy, industrial silicon, yellow phosphorus, corindon by submerged arc furnace.

Our graphite electrode contains more than 30 kinds of diameter specifications covering from 200mm to 800mm.

It divide into regular power graphite electrodes , high power graphite electrodes, ultra high power graphite electrode depending on raw material and production process, and different power and current carrying capacity in use.

Special specifications of graphite electrodes and special-shaped graphite products can be produced according to the special requirements of users.

Related listings

-

Manufacture Hp Graphite ElectrodeMinerals and ores and metals - Shandong Rongfu new material technology Co,Ltd - China - January 7, 2019 - contact company for price

Manufacture Hp Graphite ElectrodeMinerals and ores and metals - Shandong Rongfu new material technology Co,Ltd - China - January 7, 2019 - contact company for priceHP Graphite Electrode HP Graphite Electrodes For Arc Furnaces HP Graphite Electrode Manufacture Electric resistivity : 5.5-6.8 Bending strength: >=10.0 Elastic Modulus: <=13 Bulk density:1.62-1.70 Ash: <=0.3 CTE: 1.80-2.20 High power graphit...

-

Hp Graphite Electrodes For Arc FurnacesMinerals and ores and metals - Shandong Rongfu new material technology Co,Ltd - China - January 7, 2019 - contact company for price

Hp Graphite Electrodes For Arc FurnacesMinerals and ores and metals - Shandong Rongfu new material technology Co,Ltd - China - January 7, 2019 - contact company for priceHP Graphite Electrodes For Arc Furnaces HP Graphite Electrode Manufacturer Electric resistivity : 5.5-7.0 Bending strength: >=8.5 Elastic Modulus: <=13 Bulk density: 1.62-1.70 Ash: <=0.3 CTE: 1.80-2.20 High power graphite electrode is a grap...

-

Manufacture Uhp Graphite ElectrodeMinerals and ores and metals - Shandong Rongfu new material technology Co,Ltd - China - January 7, 2019 - contact company for price

Manufacture Uhp Graphite ElectrodeMinerals and ores and metals - Shandong Rongfu new material technology Co,Ltd - China - January 7, 2019 - contact company for priceShandong Rongfu new material technology Co, Ltd., which is located in Shandong province, China, have been specialized in the graphite electrode field for UHP Graphite Electrodes, Oxidation Resistance Graphite Electrode, UHP Graphite Electrodes Oxidat...

Safe Trade Tips

- Ask for business references and check them

- Use a payment method that offers better protection for all such as Letters of credit and verified professional escrow services. Avoid payments in advance such as money transfers

- Verify their business via their local Chamber of Commerce

- Search the internet using their website address, their business name, their phone and fax numbers, and their email addresses to see if you can find any feedback about them.

- Get to know more about scams and fraud to avoid: Internet Crime Complaint Center - Consumer Financial Protection Bureau

- This site is never involved in any transaction, and does not handle payments, shipping, guarantee transactions, provide escrow services, or offer "buyer protection" or "seller certification"