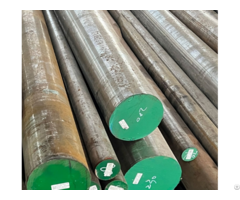

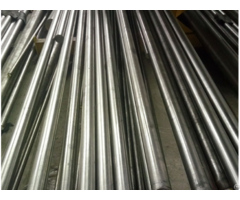

Nitriding Treatment Skd11 Mold Steel Wide Range Of Uses - China

price: 781.00 Dollar US$

skd11 mold steel nitriding treatment

after the nitriding treatment of the mold or workpiece, a layer of hardened structure with high hardness and certain corrosion resistance is formed on the surface.

the surface hardness of the workpiece nitrided at 525°c is about 1250hv.

the effect of nitriding time on the nitrided layer is as shown in the table below.

nitriding time (hours) 20 30 60 nitriding layer depth mm 0.25 0.30 0.35 soft nitriding treatment at 570℃

the surface hardness of the workpiece is approximately 950hv.

usually, after 2 hours of soft nitriding treatment, the depth of the hardened layer can reach 10-20um.

grinding the mold base or working in a low-temperature tempering state is prone to grinding cracking.

in order to prevent the occurrence of cracks, small grinding feeds should be used for multiple grinding times, and good water cooling conditions should be added.

when molds with complex shapes or large sizes are processed by wire cutting, cracking will usually occur when the molds are finally processed by wire cutting.

in order to prevent cracking, it is recommended to use gas quenching and high-temperature tempering to reduce heat treatment stress, or to perform cavity preprocessing on the mold base.

songshun specialized in special steel for almost 20 years.

we can supply mold steel, high speed steel, alloy steel, free cutting steel and etc.

welcome your contact 24 hours a day!!!songshun company website:

https: //songshunsteel.

com/

songshunsteel20240115

Company Contact:

- Posted By: Dongguan Songshun Mould Steel Co., Ltd.

- Phone: 076985475596

- Address: 1st Floor, No. 1, Dongda Fourth Street, Shatou Community, Chang'an Town, Dongguan , Guangdong , China

- Email:

- Website: https://songshunsteel.com/

Published date: May 5, 2024

- Business Description: Established in 2009,Songshun Steel supplies a wide range of carbon, alloy and tool steel products, including high speed tool steel, cold work tool steel, hot work tool steel, plastic mould steel, engineering steel and machine structural steel etc.

After more than 10 years development and growing, Songshun Steel becomes one comprehensive special steel factory, stockist and exporter.

Combined with experienced exporting team and professional technical knowledge, Songshun Steel offers both technical advice and support, as well as global professional steel solution and service.

Due to satisfactory reliable quality and professional service, Songshun expands our market worldwide, such as Colombia, Chile, Spain, Turkey, Iran, Vietnam, Malaysia ,UAE, Canada, Brazil, Mexico and so on.

Songshun specialized in Special Steel for almost 20 years.

We can supply mold steel, high speed steel, alloy steel, free cutting steel and etc.

Welcome your contact 24 hours a day!!!

Skype/Whatsapp/We chat: +86-18269260283

Songshun Tiktok: mikizhuo

Songshun Facebook: Songshun Steel

Songshun YouTube: MiKi Zhuo

songshunmoldsteel414 04340

Related listings

-

Excellent Hardness And Durability Cr12mov MaterialMinerals and ores and metals - Dongguan Songshun Mould Steel Co., Ltd. - China - May 5, 2024 - 695.00 Dollar US$

Excellent Hardness And Durability Cr12mov MaterialMinerals and ores and metals - Dongguan Songshun Mould Steel Co., Ltd. - China - May 5, 2024 - 695.00 Dollar US$cr12mov material is known for its excellent wear resistance, hardness, strength, heat resistance and fatigue resistance. it is widely used in tool manufacturing, mold manufacturing and mechanical parts processing, and is favored by many industries. c...

-

High Quality Production Gb Cr12mov Mold Steel In ChinaMinerals and ores and metals - Dongguan Songshun Mould Steel Co., Ltd. - China - May 5, 2024 - 699.00 Dollar US$

High Quality Production Gb Cr12mov Mold Steel In ChinaMinerals and ores and metals - Dongguan Songshun Mould Steel Co., Ltd. - China - May 5, 2024 - 699.00 Dollar US$gb cr12mov mold steel has excellent hardness and strength. after proper heat treatment, it can reach a hardness of hrc60-62, making it excellent in processes such as cutting and stamping. at the same time, its strength is also very high, it can withs...

-

Heat Treatment X210cr12 Material Cold Work Tools SteelMinerals and ores and metals - Dongguan Songshun Mould Steel Co., Ltd. - China - May 5, 2024 - 716.00 Dollar US$

Heat Treatment X210cr12 Material Cold Work Tools SteelMinerals and ores and metals - Dongguan Songshun Mould Steel Co., Ltd. - China - May 5, 2024 - 716.00 Dollar US$the characteristics of x210cr12 material are as follows: high hardness: after proper heat treatment, the hardness of x210cr12 can reach 58~62 hrc, which allows the tool to remain sharp after long-term use and is not easy to lose cutting ability. impa...

Safe Trade Tips

- Ask for business references and check them

- Use a payment method that offers better protection for all such as Letters of credit and verified professional escrow services. Avoid payments in advance such as money transfers

- Verify their business via their local Chamber of Commerce

- Search the internet using their website address, their business name, their phone and fax numbers, and their email addresses to see if you can find any feedback about them.

- Get to know more about scams and fraud to avoid: Internet Crime Complaint Center - Consumer Financial Protection Bureau

- This site is never involved in any transaction, and does not handle payments, shipping, guarantee transactions, provide escrow services, or offer "buyer protection" or "seller certification"