Dtf Printer Direct To Film Inks And Supplies - China

price: 4050.00 Dollar US$

DTF Printing Process | Making the DTF Transfer

Step 1: Print on the Film

Insert the PET film in the printer trays.

Hit Print.

The inkjet printer will print “direct to film”, transferring the image onto your PET film.

Be careful not to smudge the print when you remove it from the tray! Step 2: Spread the Powder

This step is the application of hot-melt powder on the film that has the printed image on it.

You have to apply the powder while the print is still wet! Make sure and spread the powder evenly.

Normally you would keep a tray next to the printer, sprinkle the power onto the web print, then seasaw back and forth until it covers the wet ink.

Then CAREFULLY shake off the excess.

Alternately, one can use automated shakers available for busier custom t-shirt shops.

Step 3: Melt the Powder

Just like the description indicates, your next step is to actually melt the powder in place.

The most common way to do this is just to put the direct to film DTF transfer in an oven for about 2 minutes.

Alternatively, if you’re already in the custom t-shirt business doing DTG or vinyl or white toner printer transfers you can use your heat press.

Just make sure you are hovering and not applying any pressure.

Or that the top of the press isn’t in contact with the transfer at all.

There are no times and temperatures for curing DTF transfers here on purpose.

It’s always best to check with the manufacturer! Step 4: Pre-Pressing the T-Shirt

It doesn’t have to be a t-shirt of course.

But whatever you’re going to apply your DTF transfer to should be completely smooth.

Any wrinkles will show up in the print! And maybe even more importantly it will completely dry the material.

You’d be surprised how much moisture fabric can absorb from humidity in the air, and that would affect print quality.

DTF Printing Process | Making the Custom T-Shirt

2 color dtf printed shirtStep 5: Applying the DTF Transfer

Once you’ve made a direct to film transfer you do NOT need to use it right away.

Like most other kinds of transfers, they store well.

That’s why so many small businesses focus on just selling the transfers themselves! If your wondering which DTF printer to buy? check out the link.

The PET film with the image and the melted powder is placed on the pre-pressed material in the heat press.

You’ll then heat press the transfer onto the shirt just like you would any other, following the current manufacturer’s instructions of course.

Unlike throwing a screen printed shirt into a tunnel dryer, this process is usually recommended to take less than : 30 - Step 6: Peel DTF Transfer

DTF uses a COLD PEEL.

100% of the time.

So after heat pressing onto a shirt, set it aside until the fabric and transfer are completely cooled off.

If you are doing a run of shirts you can just press them all, one after the other, and start peeling when they are all cooled off.

The hot-melt as it cools down acts as a binder that bind the colored pigment in the inks with the fibers of the fabric.

Once the film is cooled, peel off the transfer and leave the required design behind! Step 7: Direct to Film Finishing Press

This is an optional step, but you should definitely do it on every garment application.

Like with white toner printer transfers, DTF require that final press to really cement the longevity of the printer.

It improves wash “fastness” by leaps and bounds.

Normally, you’re just investing about 10 to 15 more second for this final step.

DTF (direct to film) doesn’t have the same limitations of sublimation – which can’t be applied to cotton – or DTG – which you can’t print onto dark polyesters.

It produces a pretty amazing transfer.

You can apply it to almost any fabric!

Company Contact:

- Phone: +8613424831086

- Address: Second, Third And Fourth Floors, No. 33, Shahe Road, Dakang Community, Yuanshan Street, Shenzhen, Gu, ShenZhen , GuangDong , China

- Email:

- Website: https://byhsh.en.ec21.com/

Published date: April 18, 2023 - Modified date: April 18, 2023

- Business Description: Shenzhen Colorgood Intelligent Equipment Co., Ltd. is a high-tech enterprise combining R&D, production, marketing and service of digital printing equipment.

Our professional R&D and technical team with more than ten years of experience in digital printing equipment R&D.

Provide customers with high-quality and efficient application solutions.

Colorgood adhere to the concept of People-Oriented, Quality First, and serve to future as our are willing to coopertae with every customers, learning togther, researching togther and exploreing the bright future of digital printing! Colorgood main products: digital printing machines, DTF printers, digital printing ovens, pre-treatment liquid spraying machines and other products.

Related listings

-

Dtf Printer Direct To Film PrintingPrinting and publishing equipment - Shenzhen Colorgood Intelligent Equipment Co., Ltd - China - April 18, 2023 - 6500.00 Dollar US$

Dtf Printer Direct To Film PrintingPrinting and publishing equipment - Shenzhen Colorgood Intelligent Equipment Co., Ltd - China - April 18, 2023 - 6500.00 Dollar US$DTF Printing Process | Making the DTF Transfer Step 1: Print on the Film Insert the PET film in the printer trays. Hit Print. The inkjet printer will print “direct to film”, transferring the image onto your PET film. Be careful not to smudge the prin...

-

Catalog PrintingPrinting and publishing equipment - ZXCHINA INDUSTRIAL LIMITED - China - December 5, 2022 - 0.10 Dollar US$

Catalog PrintingPrinting and publishing equipment - ZXCHINA INDUSTRIAL LIMITED - China - December 5, 2022 - 0.10 Dollar US$Catalogue Printing Size: 8.5 x 11 inches. Cover: 350gsm pearl paper, sport UV, text 150gsm gloss art paper, all page over gloss varnish. Binding: pefect bound. Surface: three holed. Beautiful catalogue, high quality catalogue.

-

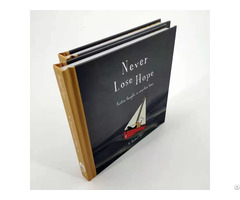

Hardcover Book PrintingPrinting and publishing equipment - ZXCHINA INDUSTRIAL LIMITED - China - December 5, 2022 - 0.10 Dollar US$

Hardcover Book PrintingPrinting and publishing equipment - ZXCHINA INDUSTRIAL LIMITED - China - December 5, 2022 - 0.10 Dollar US$High quality Hardboard book printing, 1. size: customized 2. paper materials: 600gsm C1S glossy art paper. 3. pages account : Customized 4. printing color: full color printing. 5. Finishing printing arts: glossy lamination for the cover and glossy UV...

Safe Trade Tips

- Ask for business references and check them

- Use a payment method that offers better protection for all such as Letters of credit and verified professional escrow services. Avoid payments in advance such as money transfers

- Verify their business via their local Chamber of Commerce

- Search the internet using their website address, their business name, their phone and fax numbers, and their email addresses to see if you can find any feedback about them.

- Get to know more about scams and fraud to avoid: Internet Crime Complaint Center - Consumer Financial Protection Bureau

- This site is never involved in any transaction, and does not handle payments, shipping, guarantee transactions, provide escrow services, or offer "buyer protection" or "seller certification"