Clay Brick Automatic Stacking Systemlifter Device Electrical System Smooth Operation - China

price: contact company for price

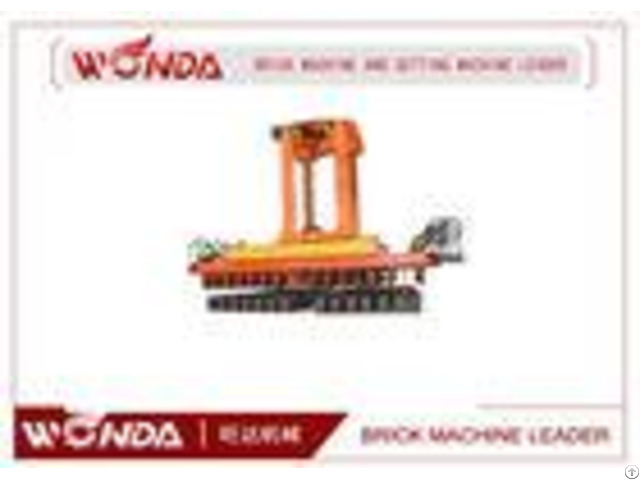

ZMP Series Auto Brick Setting Machine/ Clay Automatic Brick Stacking Machine/ Brick Lifter Brick Setting Machine Production Introduce ZMP Series Auto Brick Setting Machine / Clay Automatic Brick Stacking Machine / Brick Lifter Brick Setting Machine, The automatic hydralic brick setting machine (ZMP) is mainly used in tunnel kilns once brick stacking and firing and hoffman kilns twice brick stacking and firing, automatic contral and hydralic lifting with the feartures of energy-efficient, simple maintenance, low cost, stable and smooth operation.

The automatic hydralic brick setting machine is formed by walking car, chuck, separating machine, lifting guide pillar, rail, hydralic system and electrica system, etc.

Technical Parameters - - - - Name | Brick Setting Machine | Processing | Brick Production Line | Model Number | ZMP Series | Capacity | 12000 Pcs/H | Working Frequency | 40 (S/Time) | Load Weight | 1 Ton | Setting Capacity | 240(Piece/Time) | Highly | 0-1.725 (m) | - - - - Operating principle The operating principle of automatic hydralic brick setting machine: - - - - 1 | the cutting machine will push the wet bricks onto the storage transition table.

| 2 | when the pieces of wet bricks on the storage transition table reaches a number, the cutting machine will push the wet beicks again onto the intelligent separater table.

| 3 | The lifting cylinder will move down when the wet bricks are devided into strips on the separator table by the separatingsystem.

| 4 | Then the chuck will pick up the wet bricks by the driving of lifting cylinder to a predetermined height.

During the lifting period, the separating system will adjustt the stacking channel and brick brick space based on the kiln firing desigh.

| 5 | The wet bricks will be stacked onto the trolley car if the chuck opening the manganese plate by the cylinder.

| 6 | The brick setting machine can finish the brick stacking working through the cycle of all complete process as above.

All this functions are centralized control by electric, the operator just need to start the appropriate procedures, the brick setting machine can achieve the operating automatically.

| - - - - Production Parts The full-automatic brick setting machine is formed by moving trestle, clamp plate, separator, lifting guide pillar, rail, hydraulic system and electrical system, etc.

Characteristics 1 - The brick machine setting machine is automatic working, reduce the use of manpower, high efficiency, and large capacity 2 - ZMP series Automatic Setting Machine are applied to the first time sinter and the second sinter.

3 - And this can pick up the grouped billet automatic calmly (wet billet and dry billet) and then put down them to the assigned position in the billet lay car.

4 - There are many ways to putting down the billet, such as putting down billet in face up or putting down billet in side face.

5 - Toward to the different shape of kiln ways to putting down the billet, such as putting down billet in face up or putting down billet in side face.

6 - Toward to the different shape of kiln and different output, there are different automatic setting machines Service Policy Before-sales 1 - cept customer consultation, according to the customer demand; determine the scale of factory management, providing solutions.

2 - r customer training and technical personnel 3 - cording to customer request, design and manufacture products 4 - company sent engineering and technical personnel to the user scene, planning for the optimal design of the flow field, and the solutions.

5 - customers in relevant technical documents.

Medium-sales 1 - ceptance of the product 2 - sist client protocol construction scheme After-sales 1 - aining personnel 2 - point special after-sale service staff, arrived at the scene guide clients installation and commissioning.

3 - gular visit customer, consult with the customer feedback, come true with the customer's two-way communication Customer Visit Welcome to us, we have professional team.

We can show you our workshop to kown us more.

Engineer guide We provided installing and debugging .

About us Established in 1976s, Wangda machinery has developedinto a famous manufacturer through 40 years struggling and progressing, specialized in producing vacuum extruder, clay brick making machine, hollow brick making machine, Fired brick, Solid clay brick making machine.

Company Contact:

- Posted By: WANGDA Machinery Factory

- Phone: 86-371-64388011

- Address: No.34,XiaoYi Road,GongYi City,HeNan,China, Gongyi , Henan , China

- Email:

Published date: March 14, 2018

- Business Description: Founded in1972 , Wangda Machinery factory was formerly known as telecom tool works which belongs to Post and Telegraph Department of the Fourth Engineering company .

It locates in Gongyi City and only 600 meters away from railway station.

Related listings

-

Qp280 Fly Ash Fired Clay Brick Cutting Machinesteel Material Auto MethodPneumatic machinery - WANGDA Machinery Factory - China - March 14, 2018 - check with company for price

Qp280 Fly Ash Fired Clay Brick Cutting Machinesteel Material Auto MethodPneumatic machinery - WANGDA Machinery Factory - China - March 14, 2018 - check with company for priceQP280 Senes Double Wire Frame Clay Red Brick Cutting Machine Product Description QT-26QP280 senes full-automatic strip cutting and blank cutting machine is mainly used to cut wud which is squeezed from extruder into qualified clay brick in the proces...

-

Fully Automatic Brick Stacking Machine Pneumatic Pressure Energy Saving Mpj4 0Pneumatic machinery - WANGDA Machinery Factory - China - March 14, 2018 - check with company for price

Fully Automatic Brick Stacking Machine Pneumatic Pressure Energy Saving Mpj4 0Pneumatic machinery - WANGDA Machinery Factory - China - March 14, 2018 - check with company for priceMPJ4.0 Fully Automatic Steel Pneumatic Brick Setting Machine Wet Brick Production Introduction Automatic series brick setting machine can meet the requirement of all kinds of tunnel kiln.The setting machine with its characteristics of stability, high...

-

Gds 3000 Steel Roller Screen Concrete Block Crushersingle Deck 9r Min Rotate SpeedPneumatic machinery - WANGDA Machinery Factory - China - March 14, 2018 - check with company for price

Gds 3000 Steel Roller Screen Concrete Block Crushersingle Deck 9r Min Rotate SpeedPneumatic machinery - WANGDA Machinery Factory - China - March 14, 2018 - check with company for priceGDS 3000 Steel roller screen for Brick Crushing Machine Automatic Product Description This series roller screen have high yield, simple structure, easy maintenance, and with hit device.The hit roller repeatedly his screening surface as roller screen ...

Safe Trade Tips

- Ask for business references and check them

- Use a payment method that offers better protection for all such as Letters of credit and verified professional escrow services. Avoid payments in advance such as money transfers

- Verify their business via their local Chamber of Commerce

- Search the internet using their website address, their business name, their phone and fax numbers, and their email addresses to see if you can find any feedback about them.

- Get to know more about scams and fraud to avoid: Internet Crime Complaint Center - Consumer Financial Protection Bureau

- This site is never involved in any transaction, and does not handle payments, shipping, guarantee transactions, provide escrow services, or offer "buyer protection" or "seller certification"